Plumbing requirements, Initial set-up, Page 6 – Bunn Axiom 39130.0000J User Manual

Page 6: For more than 25 feet from the

Page 6

39130 020608

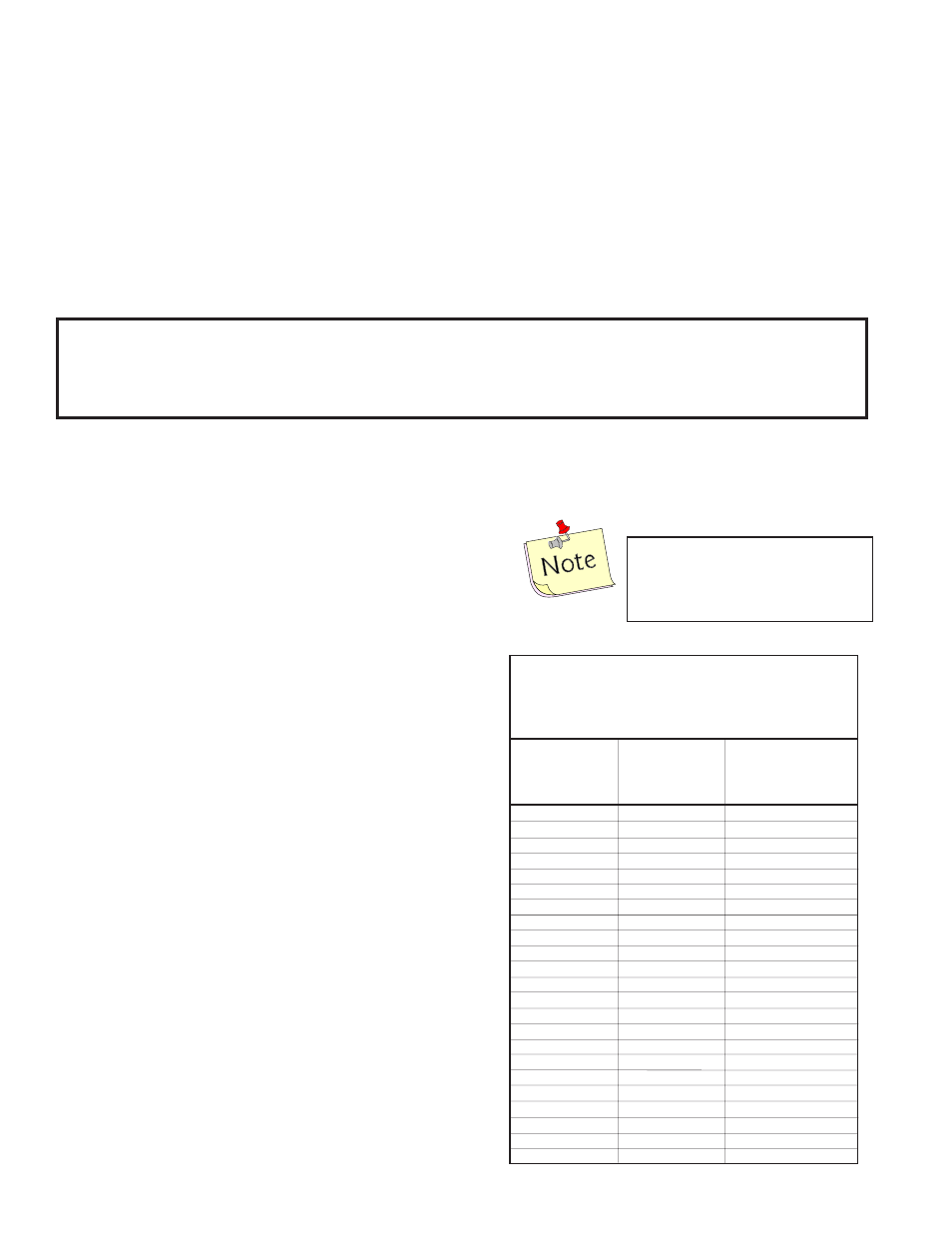

-1000

213.8

101.0

200

93.3

-500

212.9

100.5

200

93.3

0

212.0

100.0

200

93.3

500

211.1

99.5

200

93.3

1000

210.2

99.0

200

93.3

1500

209.3

98.5

200

93.3

2000

208.4

98.0

200

93.3

2500

207.4

97.4

200

93.3

3000

206.5

96.9

199

92.8

3500

205.6

96.4

198

92.2

4000

204.7

95.9

197

91.7

4500

203.8

95.4

196

91.1

5000

202.9

94.9

195

90.6

5500

201.9

94.4

195

90.6

6000

201.0

93.9

194

90.0

6500

200.1

93.4

193

89.4

7000

199.2

92.9

192

88.9

7500

198.3

92.4

191

88.3

8000

197.4

91.9

190

87.8

8500

196.5

91.4

189

87.2

9000

195.5

90.8

188

86.7

9500

194.6

90.3

187

86.1

10000

193.7

89.8

186

85.6

Brew water temperature is factory set at 200

° F (93.3° C)

Areas of high altitude will require lowering this tempera-

ture to prevent boiling. This chart should be used as a

guide when readjusting the brew water temperature.

Altitude

(Feet)

Boiling point

of water

° F ° C

Recommended

water temperature

° F ° C

1. Flush the water line and securely attach it to the inlet fitting at the rear of the brewer.

2. Turn on the water supply.

PLUMBING REQUIREMENTS

These brewers must be connected to a cold water system with operating pressure between 20

and 90 psi (138 and 620 kPa) from a

1

⁄

2

" or larger supply line. A shut-off valve should be installed in

the line before the brewer. Install a regulator in the line when pressure is greater than 90 psi (620

kPa) to reduce it to 50 psi (345 kPa). The water inlet fitting is

1

⁄

4

" flare.

NOTE - Bunn-O-Matic recommends

1

⁄

4

" copper tubing for installations of less than 25 feet and

3

⁄

8

"

for more than 25 feet from the

1

⁄

2

" water supply line. A tight coil of copper tubing in the water line will

facilitate moving the brewer to clean the counter top. Bunn-O-Matic does not recommend the use of

a saddle valve to install the brewer. The size and shape of the hole made in the supply line by this

type of device may restrict water flow.

1. Insert an empty funnel into the funnel rails.

2. Place an empty server under the funnel.

3. Connect the brewer to the power source.

4. Turn on the main ON/OFF switch located on the

left side of brewer (If equipped).

5. Water will flow into the tank and stop when the tank

is filled to its capacity. Display will show "

PLEASE

WAIT...TANK FILLING" until tank is filled with

water.

6. Wait approximately twenty minutes for the water

in the tank to heat to the proper temperature.

Display will show "

READY TO BREW...WATER

TEMP: 200°" when tank is at operating tempera-

ture. Some water will drip from the funnel during

this time; this is due to expansion and should not

occur thereafter.

7. Place a small container beneath the faucet and

open the faucet handle. Release it when you hear

the tank refilling.

8. Water volumes and flow settings have been preset

at the factory. Refer to adjustments for the Set

Brew Volumes section of this manual should the

volume need to be increased or decreased.

9. The brewer is now ready for use in accordance

with the instructions for Coffee Brewing.

10. Repeat steps 5-9 for remaining side on Twins.

INITIAL SET-UP

As directed in the International Plumbing Code of the International Code Council and the Food Code Manual

of the Food and Drug Administration (FDA), this equipment must be installed with adequate backflow pre-

vention to comply with federal, state and local codes. For models installed outside the U.S.A., you must

comply with the applicable Plumbing /Sanitation Code for your area.

If setting up new brewer in high mineral

locations, refer to programming (Enable

Brew Logic). Pertains to units with

software version 1.06 & up.