And roxul comfortboard, Vinyl wall components, Wood wall components – Roxul ComfortBatt User Manual

Page 14

14

Better

|

Best

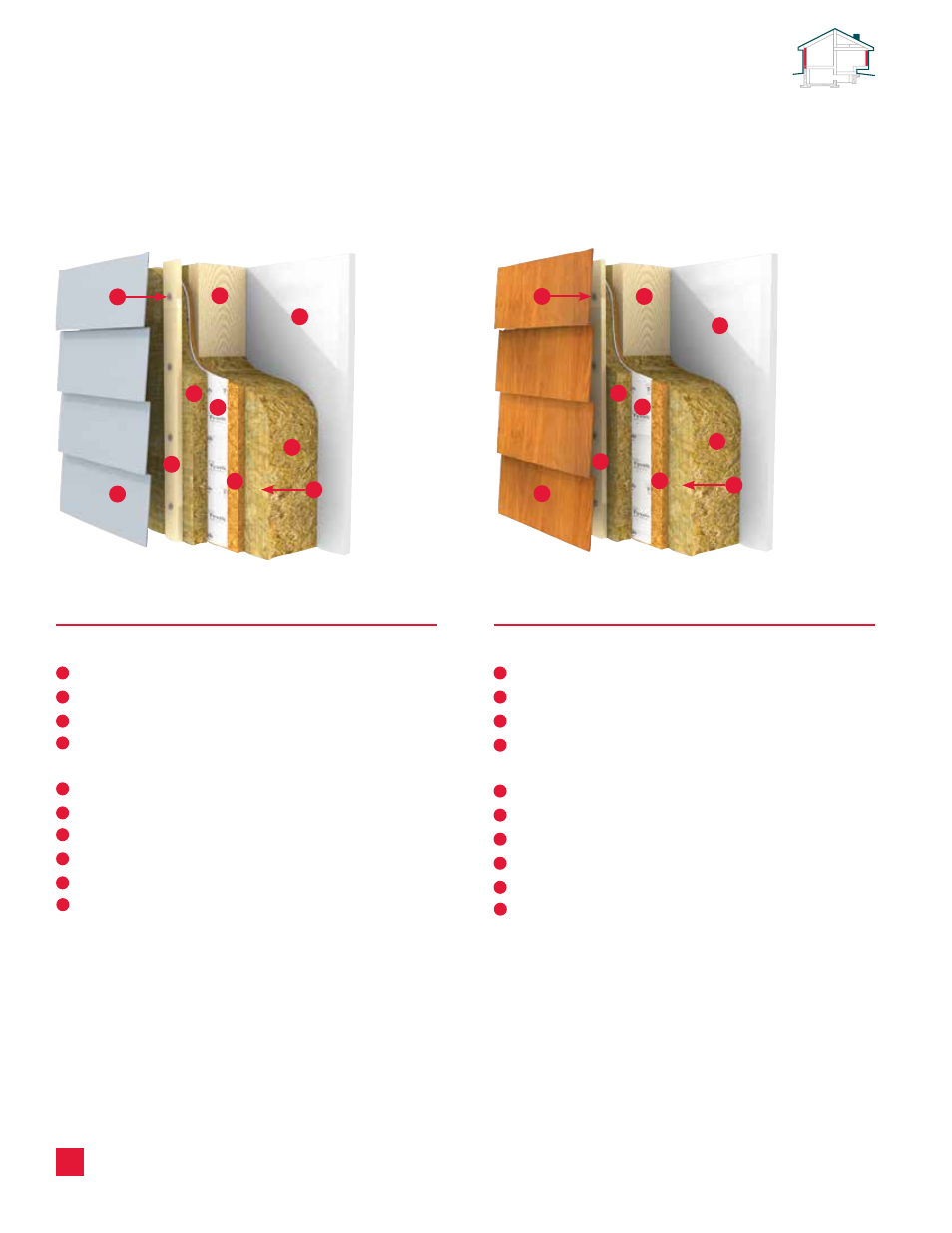

Vinyl wall components

(shown from outside to inside)

1

Vinyl siding

2

Fasteners

3

1 x 3 furring strips

4

1.25" (R5) to 3" (R12) of insulating

ROXUL COMFORTBOARd

™

IS sheathing

5

Exterior air/weather resistive barrier membrane

6

Sheathing

7

(2 x 6) stud wall

@

16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT

®

cavity insulation

9

Vapor control layer

*

10

Gypsum wall board

Wood wall components

(shown from outside to inside)

1

Wood siding

2

Fasteners

3

1 x 3 furring strips,

4

1.25" (R5) to 3" (R12) of Insulating

ROXUL COMFORTBOARd

™

IS Sheathing

5

Exterior air/moisture barrier membrane

6

Sheathing

7

(2 x 6) stud wall

@

16" o.c or best practice of 24" o.c.

8

ROXUL COMFORTBATT

®

cavity insulation

9

Vapor control layer

*

10

Gypsum wall board

Typical exterior wall claddings using ROXUL COMFORTBATT

®

and ROXUL COMFORTBOARd

™

IS.

Vinyl and wood siding

n

Minimum 1" x 3" furring strip to be placed vertically

with screw attachment of 16" OC for 16" on wood

studs and 12" OC for 24" on-center wood studs.

n

#8 or #10 screws recommended.

n

Each screw must have a minimum embedment of

1" into the wood stud or substrate.

Brick

n

Metal ties or anchors required for nailing into the

framing through the insulation boards

(to building code requirements).

n

1" (25 mm) space between the masonry and

insulation required.

1

1

2

9

9

2

3

3

4

4

7

7

5

5

6

6

8

8

10

10

*Check with your state/municipal building code for approved vapor barrier/retarder information.