Technical data, Combination d-sub connectors – Northern Connectors Conec D-Sub Combination Connectors User Manual

Page 5

6|4

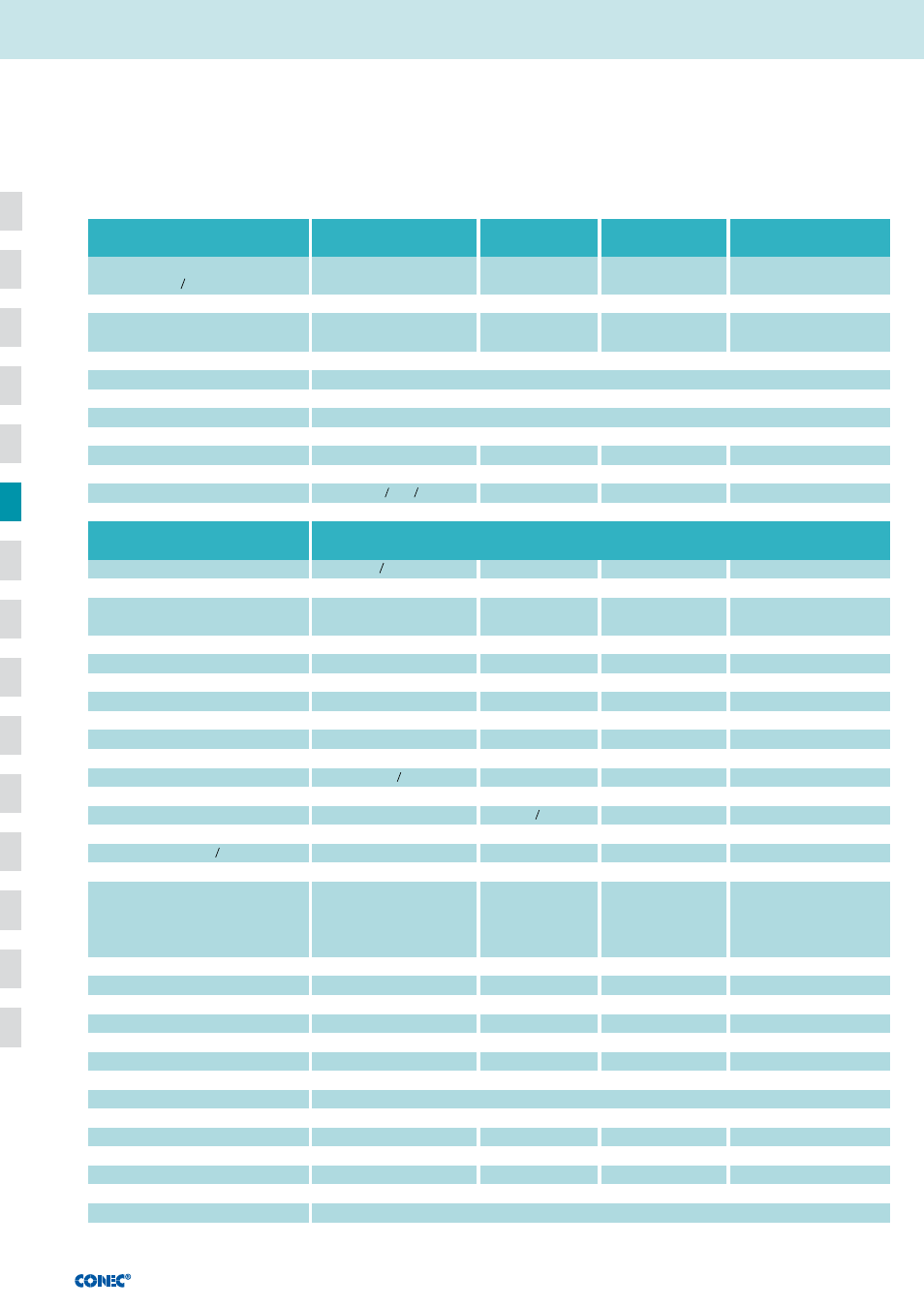

Technical Data

Materials

Connector

with signal contacts

Coaxial contacts High power contacts High voltage contacts

PBTP, GV

(UL94 V-O)

steel tin plated

Brass or stainless steel on request

Gold plated over nickel

CU alloy

CU alloy

CU alloy

PI

PTFE PBTP PI

PTFE

7.5 A (UL) 5 A (CSA, VDE)

1000 V, 50Hz

1 min.

2.7mΩ

5GΩ

10

7

mΩ

5GΩ

2x10

7

mΩ

10

16

Ωcm

50KV mm

50 75

2.7mΩ

2.7mΩ

1mΩ

2.7mΩ

1.2

1.3

1.5

750V 50Hz

3.8kV

0-2GHz

250 V

250 V

max. 2.8kV

-55°C to +125°C

3,4N

7N

7N

5N

0,2N

7N

ca. 5N

ca. 2.5N

A = Quality class 3 = 50 mating cycles, B = Quality class 2 = 200 mating cycles, C = Quality class 1 = 500 mating cycles

Combination D-SUB Connectors

Technical alterations are subject to change without notice.

Mechanical and electrical

characteristics

Insulator

Green standard black crimp

Shell

Contact plating

Contact material

PCB clip

Insulator

Current rating

Test voltage between 2 contacts

contact and shell

Resistance between mated contacts

Insulation resistance

Contact resistance

Dielectric impedance

Characteristic impedance

Contact resistance inner outer conductor

VSWR-value at according

MIL-C-39012

1.2GHz

1.5GHz

2.0GHz

Dielectric voltage

Frequency range

Working voltage

Temperature range

Insertion force per contact

Extraction force per contact

Mating cycles