Mq street pro 1 saw — preparation/pre-inspection – Multiquip SP15E16 User Manual

Page 16

PAGE 16 — SP 1 SAW — OPERATION AND PARTS MANUAL — REV. #6 (06/09/08)

MQ STREET PRO 1 SAW — PREPARATION/PRE-INSPECTION

PREPARATION / PRE-INSPECTION

1. Read and fully understand this manual,

the safety intructions in particular, and

the engine manufacturer's manual

supplied with the saw.

2. Select the correct blade for each application. If abrasive

blades are used, MAKE CERTAIN they are designed for

use on a concrete floor saw. They must be reinforced and

have a hole for the driving pin. When wet cutting with an

abrasive blade, MAKE CERTAIN the blade is intended for

wet cutting. Water will destroy a dry cut abrasive blade.

Some diamond blades require water cooling and failure to

do so will destroy them almost immediately. Other diamond

blades can be used with or without water. Refer to the Blades

and Blade Placement sections on pages 18 and 19 for further

information.

3. Handle all blades with care and NEVER use a damaged

blade. NEVER use an abrasive blade that has been

dropped.

Electric Powered Saws

1.

The motor should be connected to a power source in

compliance with all local electrical codes. This must be

performed by a qualified electrician. After this connection

is made, it will be necessary to check the rotation of the

motor shaft. The shaft rotation MUST be counter-

clockwise when viewing the motor from the shaft extension

end. If the rotation of the shaft is incorrect make the

necessary changes for the correct shaft rotation.

2.

MAKE CERTAIN the rated line voltage is at the motor when

cutting. Motors can burn out when the voltage falls 10%

below the voltage rating of the motor. Also use the correct

heavy duty circuit breakers or fuses in the circuit.

3.

MAKE CERTAIN the correct size extension cord is used.

Undersize wires will burn out motors. Use the following

chart to determine the extension cord size.

s

e

z

i

S

d

r

o

C

n

o

i

s

n

e

t

x

E

.

3

E

L

B

A

T

R

O

T

O

M

E

G

A

T

L

O

V

'

0

5

G

N

O

L

'

5

7

G

N

O

L

'

0

0

1

G

N

O

L

5

P

H

e

s

a

h

p

e

l

g

n

i

s

0

3

2

0

1

.

O

N

8

.

O

N

6

.

O

N

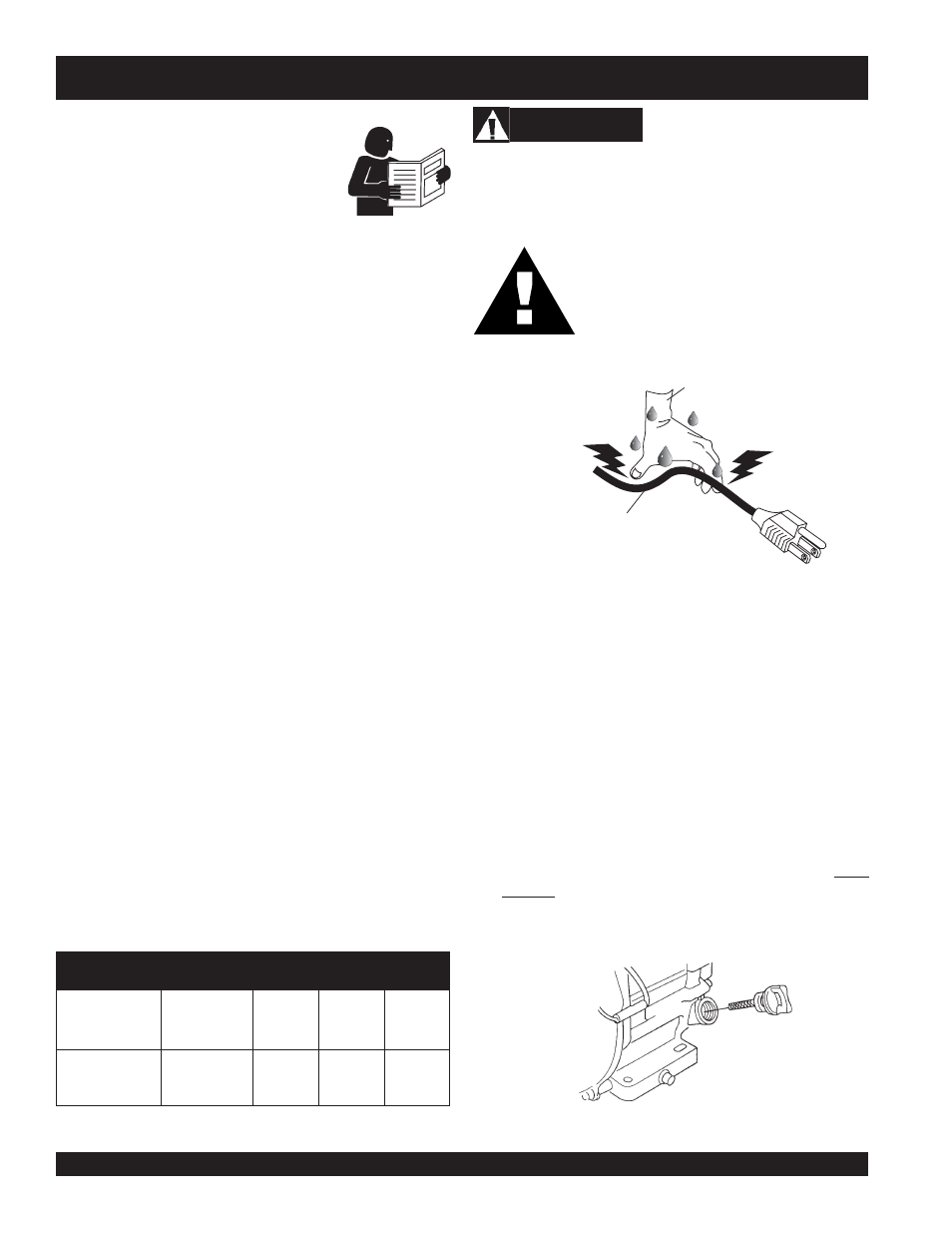

WARNING

ALWAYS use a grounded (3-wire) extension cord and MAKE

CERTAIN that the motor is connected to a properly grounded

electric circuit to protect the operator from possible electric shock.

Figure 6. Engine Oil Dipstick (Removal)

Gasoline Powered Saws

1. Clean the

saw,

removing dirt and dust, particularly the

engine cooling air inlet, carburetor and air cleaner.

2.

Check the air filter for dirt and dust. If air filter is dirty, replace

air filter with a new one as required.

3. Check carburetor for external dirt and dust. Clean with dry

compressed air.

4.

Check fastening nuts and bolts for tightness.

Engine Oil Check

1. To check the engine oil level, place the saw on secure level

ground with the engine stopped. The frame platform

must

be level

to accurately check the engine oil.

2. Remove the filler dipstick from the engine oil filler hole

(Figure 6) and wipe it clean.

NEVER!

touch the power cord (Figure 5) with

wet hands

or while

standing in water

when it is connected to a power source. The

possibly exists of electrical shock (electrocution)

even death.

NEVER!

spray water directly on

the electric motor.

POWER

CORD

(POWER ON)

WET

HANDS

Figure 5. Extension Cord (Wet Hands)