Hth — maintenance – Multiquip HTH_SERIES User Manual

Page 23

HTH-8 FT. RIDE-ON POWER TROWEL — OPERATION AND PARTS MANUAL — REV. #6 (02/22/11) — PAGE 23

HTH — MAINTENANCE

Changing A Blade

Whiteman recommends that all the blades on the entire ma-

chine be changed at the same time. If only one or some of the

blades are changed at one time, the machine will not finish

concrete consistently and the machine may wobble or bounce.

1. Place the machine on a flat, level surface. Adjust the blade

pitch control to make the blades as flat as possible. Note

the blade orientation on the trowel arm. This is important

for ride-on trowels as the two sets of blades counter-rotate.

Lift the machine up, placing blocks under the main guard

ring to support it.

2. Remove the bolts and lock washers on the trowel arm,

and then remove the blade.

3. Scrape all concrete and debris from the trowel arm. This

is important to properly seat the new blade.

4. Install the new blade, maintaining the proper orientation

for direction of rotation.

5. Affix the bolts and lock washers.

6. Repeat steps 2-5 for all remaining blades.

Checking Hydraulic Pressure

It should be mentioned that most hydraulic problems are a

result of low fluid levels. Before checking any other possibilities,

make sure the hydraulic fluid level is half way up the sight glass

which is located at the right end of the frame.

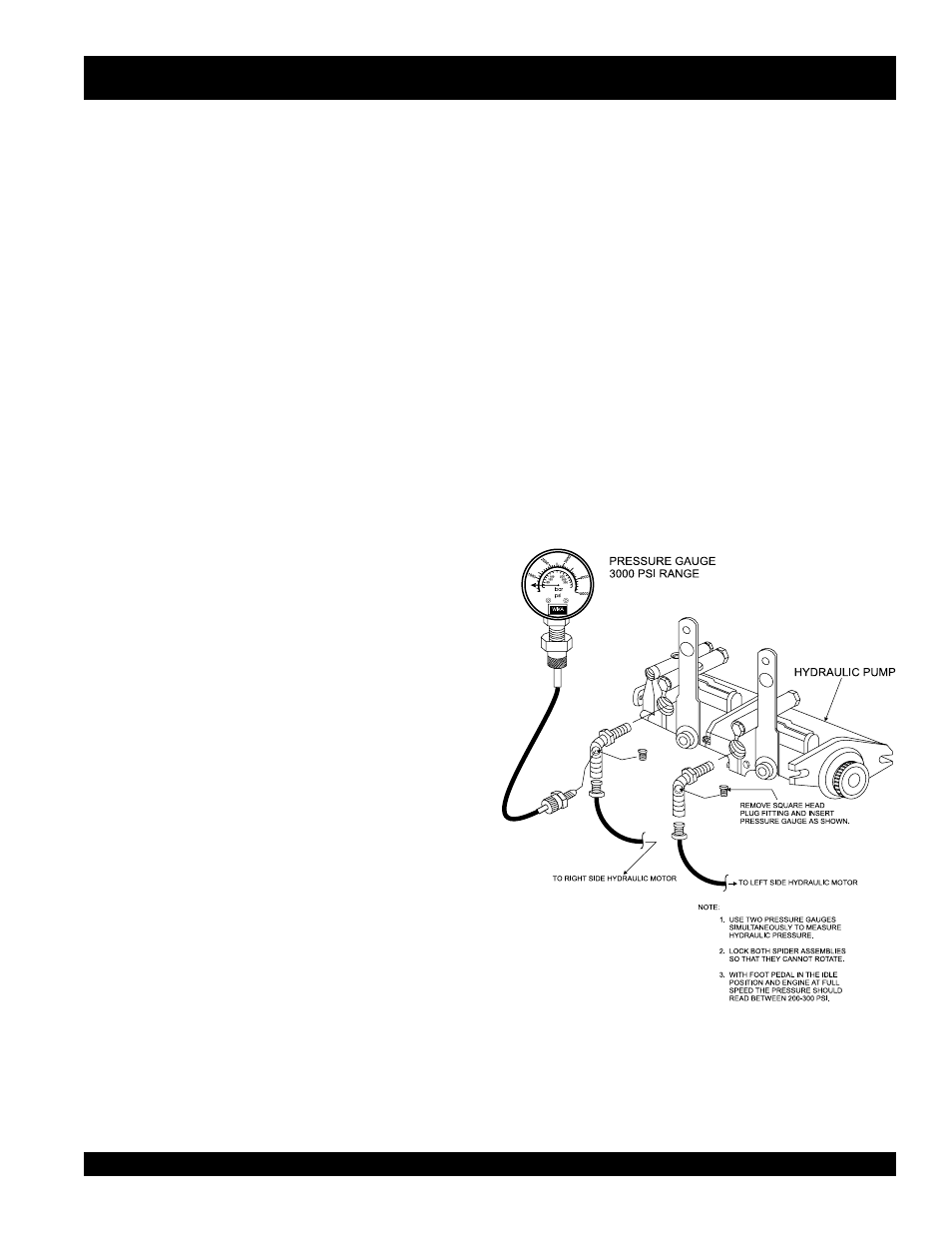

Hydraulic pressure can be checked using a pressure gauge

(Figure 18) with a range of at least 5,000 psi. The pressure taps

are located on the front side of the hydraulic pumps on elbows.

The 1/8" pipe plugs can be removed and a hose, attached to

the gauge, screwed into each port. It is best to use two gauges

simultaneously, but it is possible to use only one gauge and

repeat the procedure for each side.

To fully test the hydraulic system, the spiders will need to be

locked so that they cannot rotate. This can easily be done by

wrapping a chain around an arm on each spider, thus chaining

them together in the back of the trowel.

Figure 18. Pressure Gauge (Hydraulic Pump)

Once the pressure gauges are installed and the spiders chained

together, the system can be checked.

With the foot pedal in the idle position and the engine at full

speed, the pressure should be 200 to 300 psi. If the pressure is

less than 200 psi, the charge system may need to be inspected

and/ or serviced. In particular, the suction filter and charge

pump relief valve should be checked. The suction filter may

be plugged, or the relief valve may be stuck. Either condition

may cause low charge pressure.

With the engine at 50% to 70% of full speed, and spiders

chained together, slowly depress the foot pedal and read the

gauges. The pressure should get to at least 3,100 psi. If the

pressure will not attain 3,100 psi, the pump should be inspected

and/or serviced by an authorized service representative.