Maintenance – Multiquip WBH16EAWD User Manual

Page 26

page 26 — WBH16eaWD epa poWer Buggy • operation anD parts manual — rev. #0 (09/09/13)

pump Control lever aDjustment

If the power buggy tends to creep in the forward or reverse

direction after you release the speed control lever, the pump

control lever requires adjustment.

3. Place the machines drive wheels on jacks or blocks

free from ground contact.

4. Locate the pump control lever adjusting bolt.

5. Loosen the jam nut.

6. Start the engine and place the buggy's directional

control lever in the forward then reverse directions

while observing for wheel movement.

7. The pump lever has a very sensitive neutral position

of about 1/32" to 1/16". If the wheels are creeping,

turn the adjusting bolt in very slight increments. If

wheels are creeping in reverse, turn the adjusting bolt

counterclockwise. If wheels are creeping forward, turn

the adjusting bolt clockwise.

tires/WHeels/lug nuts

Tires and wheels are very important and critical components

of the buggy. When specifying or replacing the wheels, it

is important that the wheels, tires, and axle are properly

matched.

tires Wear/inFlation

Tire inflation pressure is the most important factor in tire life.

1. Check tire pressure when the tires are cold before

operation.

2. Do not bleed air from tires when they are hot.

3. Check inflation pressure weekly during use to ensure

the maximum tire life and tread wear.

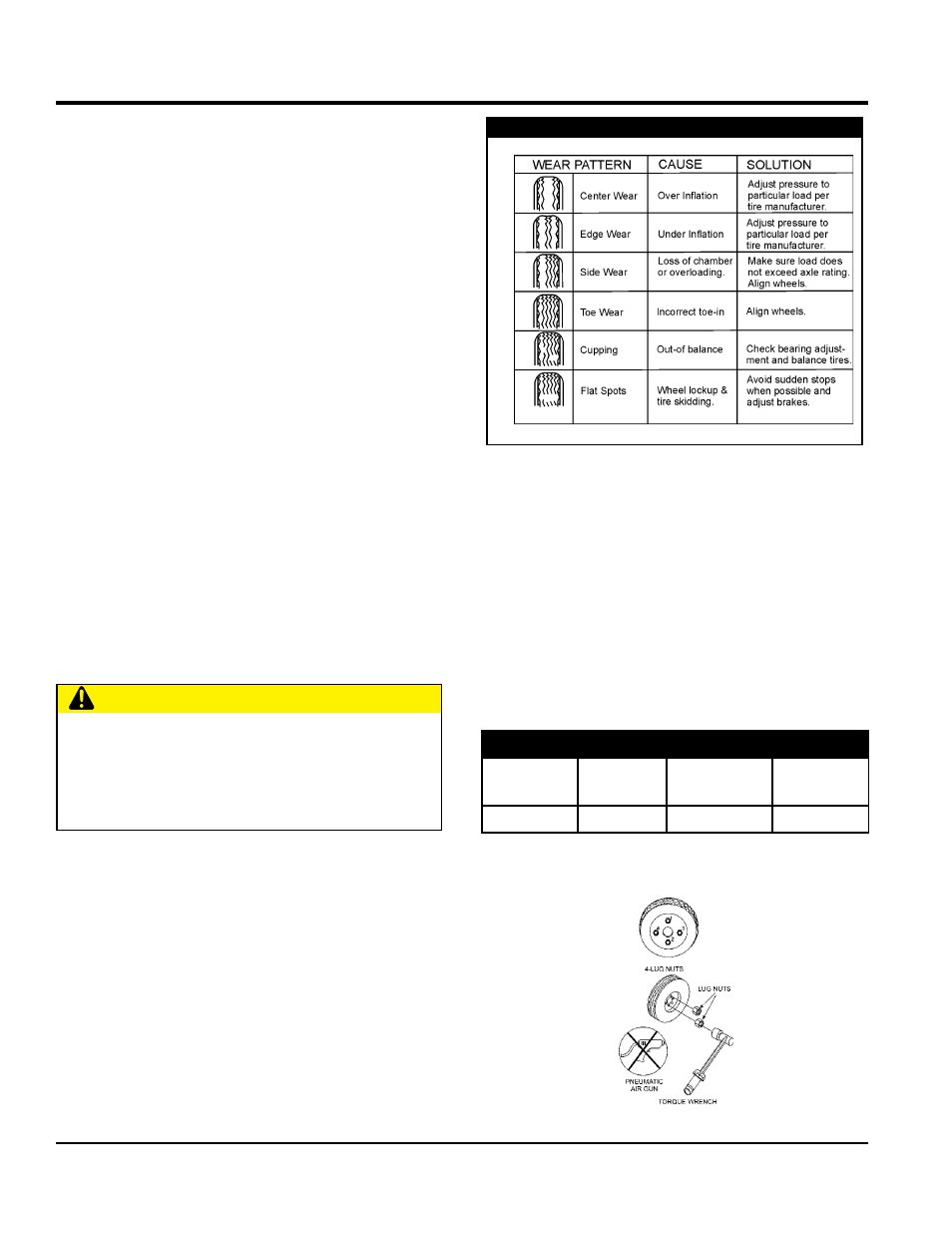

4. Refer to Table 4 (Tire Wear Troubleshooting) to pinpoint

the causes and solutions of tire wear problems.

Caution

Do not attempt to repair or modify a wheel. Do not

install an inner tube to correct a leak through the rim.

If the rim is cracked, the air pressure in the inner tube

may cause pieces of the rim to explode (break-off) with

great force and can cause serious eye or bodily injury.

MAINTENANCE

lug nut torque requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the

fasteners matched to the cone angle of the wheel. Proper

procedure for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 25. DO

NOT torque the wheel lug nuts all the way down.

Tighten each lug nut in 3 separate passes as defined

by Table 5.

3. After first road use, retorque all lug nuts in sequence

(Figure 25). Check all wheel lug nuts periodically.

Figure 25. Lug Nut Torque Sequence

table 4. tire Wear troubleshooting

table 5. tire torque requirements

Wheel Size First Pass

FT-LBS

Second Pass

FT-LBS

Third Pass

FT-LBS

480 x 8 in.

20-25

35-40

50-65