Mc-64p/s concrete mixer — maintenance (mixer) – Multiquip MC64P User Manual

Page 28

PAGE 28 —MC-64P/S CONCRETE MIXERS — OPERATION & PARTS MANUAL — REV. #7 (09/15/11)

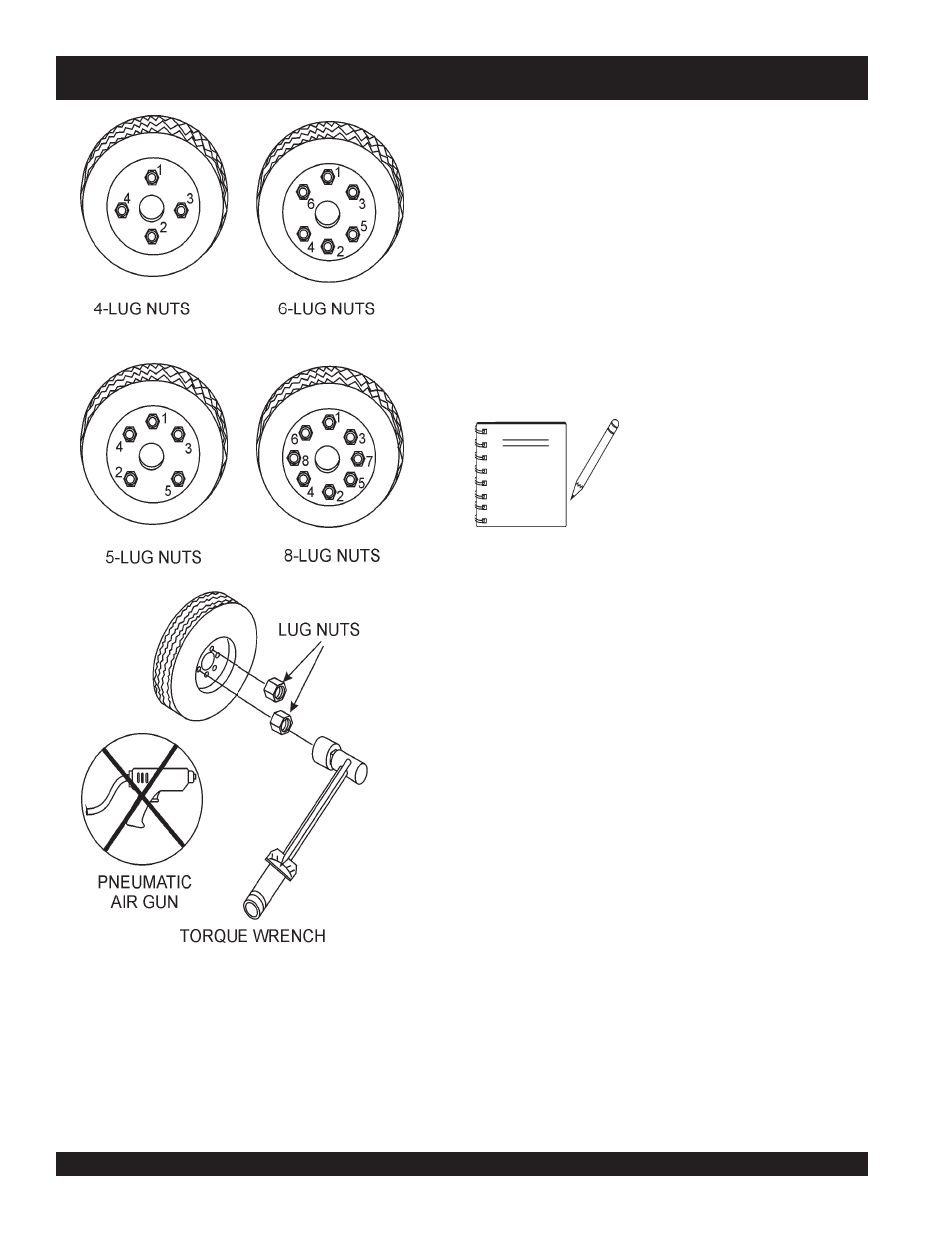

Lug Nut Torque Requirements

It is extremely important to apply and maintain proper wheel

mounting torque on the trailer. Be sure to use only the fas-

teners matched to the cone angle of the wheel. Proper pro-

cedure for attachment of the wheels is as follows:

1. Start all wheel lug nuts by hand.

2. Torque all lug nuts in sequence. See Figure 31. DO NOT

torque the wheel lug nuts all the way down. Tighten each lug

nut in 3 separate passes as defined by Table 10.

3. After first road use, retorque all lug nuts in sequence. Check

all wheel lug nuts periodically.

NEVER! use an pneumatic air gun

to tighten wheel lug nuts.

Figure 31. Wheel Lug Nuts Tightening Sequence

NOTE

Mixer Storage

For storage of the mixer for over 30 days, the following is

recommended:

Drain the fuel tank completely, or add STA-BIL to the

fuel.

Run the engine until the fuel is completely consumed.

Completely drain used oil from the engine crankcase

and fill with fresh clean oil, then follow the procedures

described in the engine manual for engine storage.

Clean the entire mixer and engine compartment.

Place the mixing drum in the down position (mouth facing

downward).

Cover the mixer and place it a clean dry area, that is

protected from harsh elements.

MC-64P/S CONCRETE MIXER — MAINTENANCE (MIXER)