Em-90 plaster/mortar mixer — maintenance (mixer), Caution – Multiquip EM90P User Manual

Page 30

PAGE 30 — EM-90 PLASTER/MORTAR MIXER — OPERATION MANUAL — REV. #2 (12/11/06)

EM-90 PLASTER/MORTAR MIXER — MAINTENANCE (MIXER)

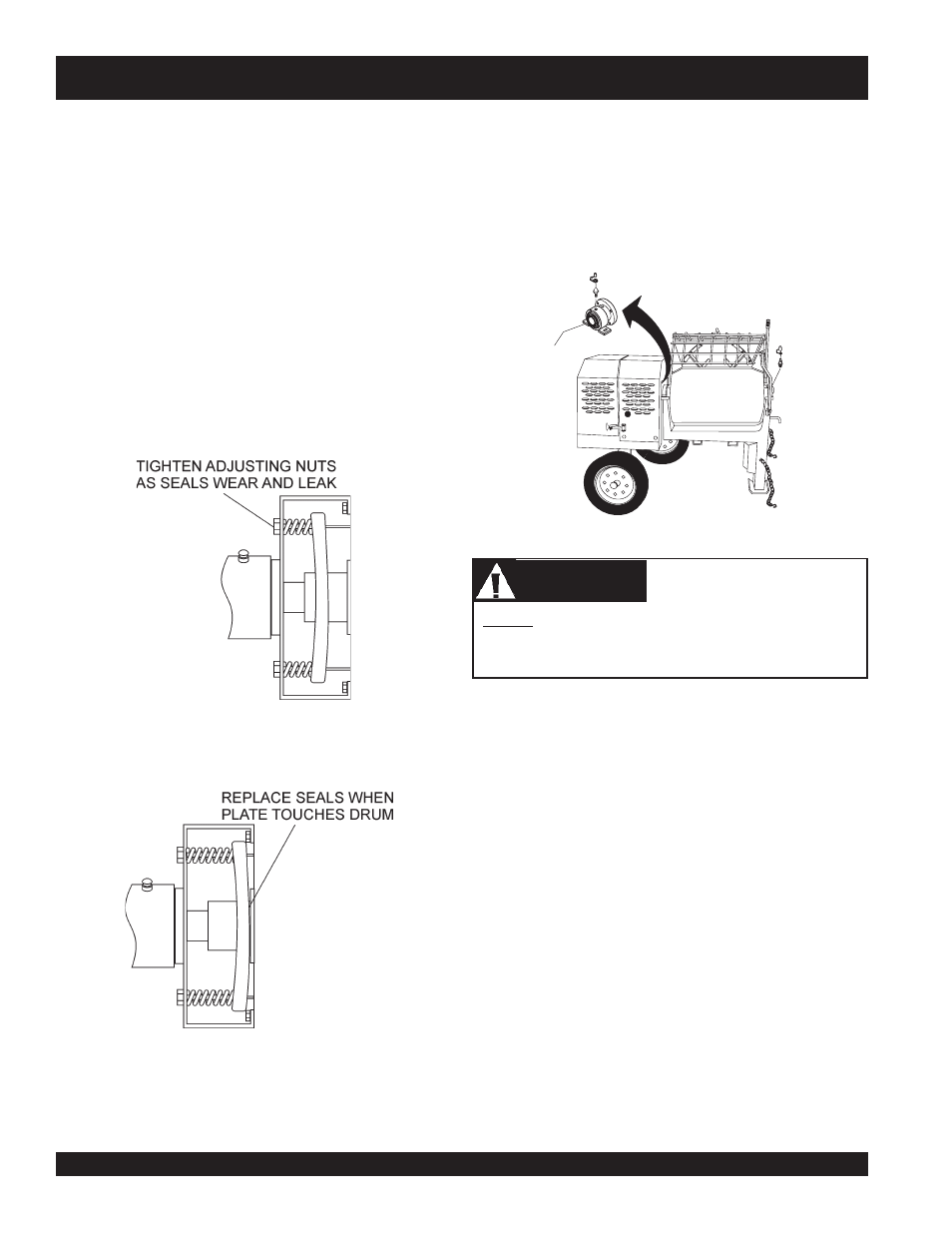

Drum Head Seals

On each end of the mixing drum there is a drum head

containing self-adjusting graphite seals. These seals consist

of packing rings, split gland and spring activated adjusters.

A properly maintained seal prevents material from working

around the shaft, causing excessive wear. The following is

the suggested procedure of maintenance for protection of

the paddle shaft.

1. Keep drum head clean of material build up so the spring

adjusters are free to work.

2. As the seals naturally wear, material will seep from the

drum head. Tighten the adjusting nuts equally until a

slight pressure is felt (Figure 27). The seals are now

tight. This procedure should be done periodically as the

seals leak.

Figure 27. Drum Seal Adjusting Nuts

3. Once the pressure plate touches the drum, its time to

replace the graphite seals (Figure 28).

Figure 28. Replacing Drum Seals

Drum Bearing Bracket Lubrication

There is 1 set of drum bearing brackets (Figure 29) that will

require lubrication. These brackets are intended to make

the drum rotate freely. Lubricate the grease fitting for each

drum bearing bracket

every month or when the drum

becomes difficult to position using multi-purpose grade

grease.

Figure 29. Grease Fittings (Dumping Mechanism)

GREASE FITTING

AND CAP

DRUM BEARING

BRACKET

GREASE FITTING

AND CAP

20

Failure to lubricate the drum bearing grease fittings

periodically will cause the dumping mechanism to stiffen,

making the mixing drum hard to dump.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

Lubricating the

Grease Fittings

Ball Socket and Clamp Face Maintenance

1.

If the towing vechicle is equipped with a ball socket,

smear socket periodically with multi-purpose grease.

This will keep the ball socket well lubricated.

2.

Periodically oil

pivot points and clamp face surfaces

of coupler with SAE 30 WT. motor oil.

3.

When parking or storing your mixer. Keep the coupler

off the ground so dirt will not build up in the ball socket.