Tig pulsing, Tigweld® 250 ex – Longevity TIGWELD 250 EX User Manual

Page 12

TIGWELD® 250 EX

11

TIG pulsing

The welding current set at the start of the welding procedure is not necessarily ideal for all

welding process:

- if the current is too low, the base material will not melt sufficiently,

- if overheating occurs, the liquid weld pool may drip.

The TIG pulsing function offers a solution (TIG welding with pulsing welding current): a low

base current I-G rises steeply to the significantly higher pulsing current I1 and, depending on the

set dcY (duty cycle) time, drops back to the base current I-G. In TIG pulsing, small sections of

the welding location melt quickly and then solidify again quickly.

In manual applications using TIG pulsing, the filler wire is applied in the maximum current

phase (only possible in the low frequency range: 0.25 - 5 Hz). Higher pulsing frequencies are

mainly used in automatic mode to stabilize the arc.

TIG pulsing is used for out-of-position welding of steel pipes or when welding thin sheet.

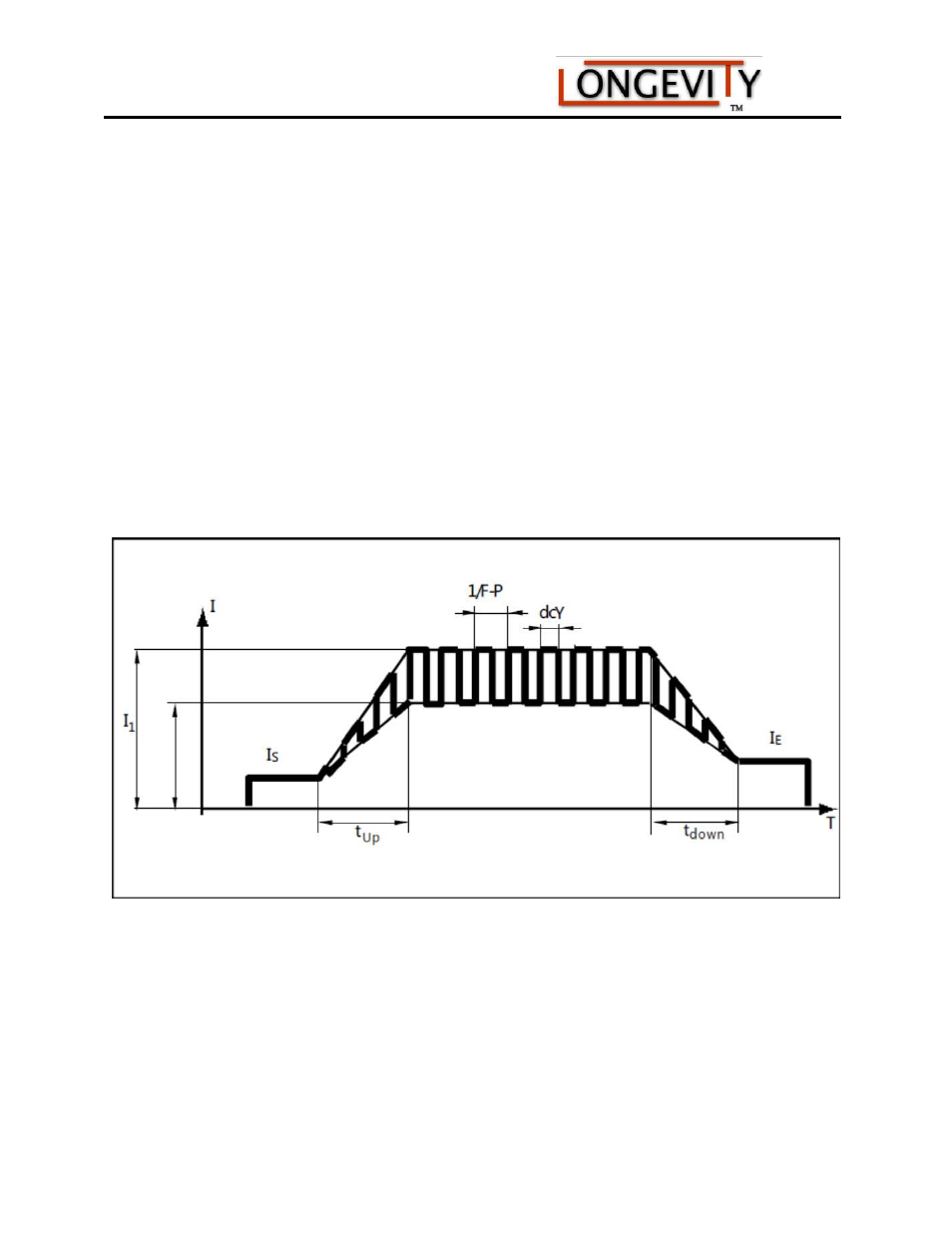

Mode of operation of TIG pulsing when TIG DC welding is selected:

Legend:

- IS Starting current

- IE Final current

- tUp Upslope

- tDown Downslope

- F-P Pulsing frequency

(1/F-P = time interval between 2

pulses)

- dcY Duty cycle

- I-G Base current

- I1 Main current