Welding wires – Longevity PROMTS 252i User Manual

Page 14

PROMTS 252i

13

Shielding Gas

Co2 should be used with thick materials, but is too hot for thinner materials.

Thin steel should be used with 75% Argon/25% Co2.

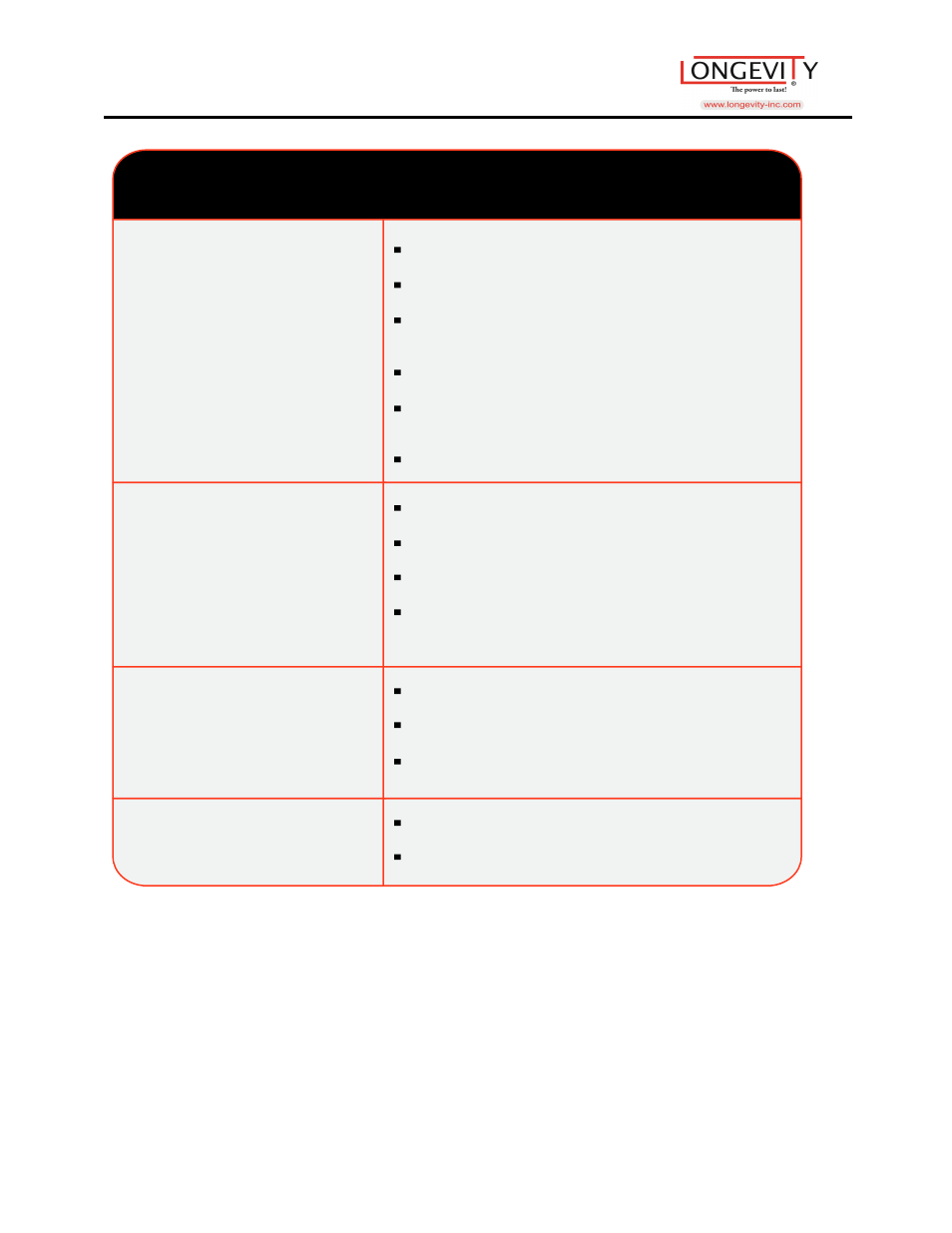

WELDING WIRES

Shielding gas- C02 or 75%Argon/25%

CO2 is recommended and will give you deeper penetration

75%Argon/25% will give you less splatter and a nicer

lookingbead

Should be used indoors, where wind cannot harm you weld.

Allows you to weld materials thinner than what you would

weld with flux cored wires

Great for auto body work

.

Shielding gas- not needed

Can be used outside, wind will not harm your weld

Great for use on aged or rusty metals

Burns hotter than solid wires, allowing for welding of

materials thicker than 18 gauge

.

Shielding gas- Argon only

Should be used with a spool gun

Gives you a strong weld

.

Shielding gas- Trimix

Use on stainless metals 301-305 and 308

.

Solid

Carbon-Steel

ER70S-6

Aluminum

ER5356

Flux Cored/

Carbon-Steel

E71TGX

Stainless Steel

ER308L