Kifco T40x1320 360,000 - 380,539 Operator Manual User Manual

Page 33

32

--Maintenance and Adjustment--

Caution! Never attempt to retime the Water-Reel without first

pulling all the tube out. Changing the timing with some of the tube

still on the spool may result in damage to the irrigation tube and/or

the Water-Reel.

2. Observe the position of the levelwind carrier drive lug on the horizontal levelwind

chain. (The chain that runs left to right just behind of the compensation bar).

The drive lug must be in its most extreme position (half way around the sprocket

and on the same side of the Water-Reel as the spool elbow. (See diagram).

3. To change the timing, remove the shield and the cap screws from the levelwind

input sprocket. Rotate the hub of the gearbox shaft until the drive lug is

positioned as described in step #2. Re-install the cap screws in the new position.

Reinstall the levelwind drive chain shield.

Gear Box Neutral-Shift and Handle

The gearbox must be shifted to neutral prior to tube pull out, and re-engaged at the

beginning of the irrigation run.

Drive Roller Adjustment

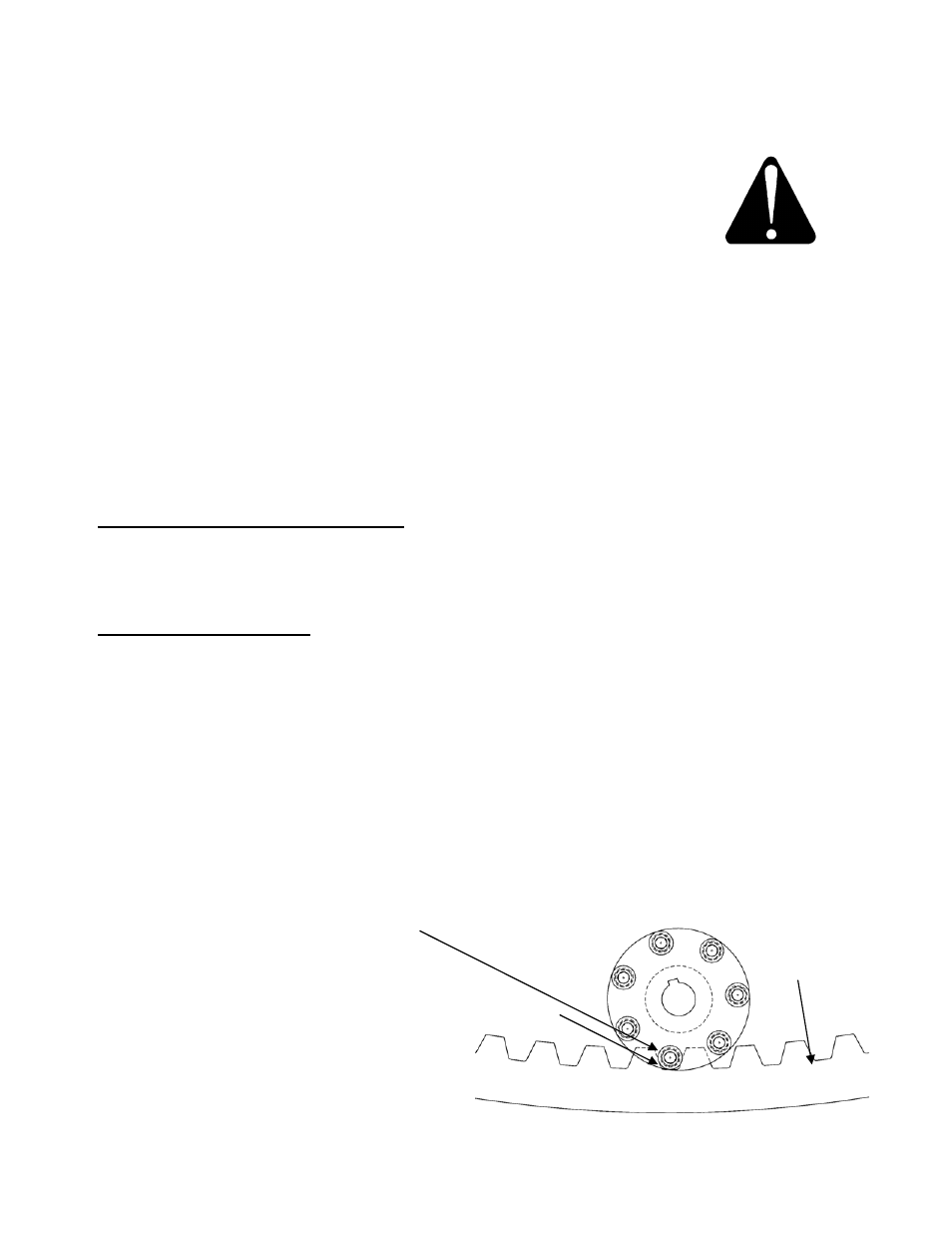

If the drive system has been disassembled, it will be necessary to adjust the mesh of the

ring gear teeth to the gearbox drive roller. The ring gear is a large part that will not be

perfectly concentric. Tape or fix a felt tip marker to a frame member and rotate the drum

with the marker touching the outside face of the main gear. This will mark the point in

which the ring gear teeth are closest to the drive roller. Rotate to this point on the ring gear

so it is exactly at the drive roller. The clearance is adjusted by moving the clamps that

fasten the gearbox mount to the frame of the Water-Reel. Lower the gearbox until the drive

roller just contacts the crotch of the teeth of the ring gear, then tighten the gearbox

mounting bolts. A scissor jack is ideal for raising & lowering the gearbox. Rotate the spool

to be sure the roller to ring gear setting is correct with no interference.

Pinion drive roller

Ring

gear

Point on ring gear that is closest to pinion drive rollers

- E37x1220 360,000 - 380,539 Operator Manual T37x1220 360,000 - 380,539 Operator Manual E33x1120 360,000 - 380,539 Operator Manual E30x1200 360,000 - 380,539 Operator Manual T33x1120 360,000 - 380,539 Operator Manual T30x1200 360,000 - 380,539 Operator Manual E30x980 360,000 - 380,539 Operator Manual T30x980 360,000 - 380,539 Operator Manual