Availability, Printing parameters, Recommended reflow profile – HMC Electronics R562 Kester Solder Paste User Manual

Page 2: Cleaning, Storage, handling, and shelf life, Health & safety

Application Notes

Availability:

R562 is commonly available in the Sn63Pb37 and Sn62Pb36Ag02 alloys. Type 3 powder mesh is

recommended, but different powder particle size distributions are available for standard and fine pitch

applications. For specific packaging information see Kester's Solder Paste Packaging Chart for available

sizes. The appropriate combination depends on process variables and the specific application.

Printing Parameters:

Squeegee Blade

80 to 90 durometer polyurethane or stainless steel

Squeegee Speed

Capable to a maximum speed of 150 mm/sec (6 in/sec)

Stencil Material

Stainless Steel, Molybdenum, Nickel Plated, Brass

Temperature/Humidity

Optimal ranges are 21-25°C (70-77°F) and 35-65% R.H.

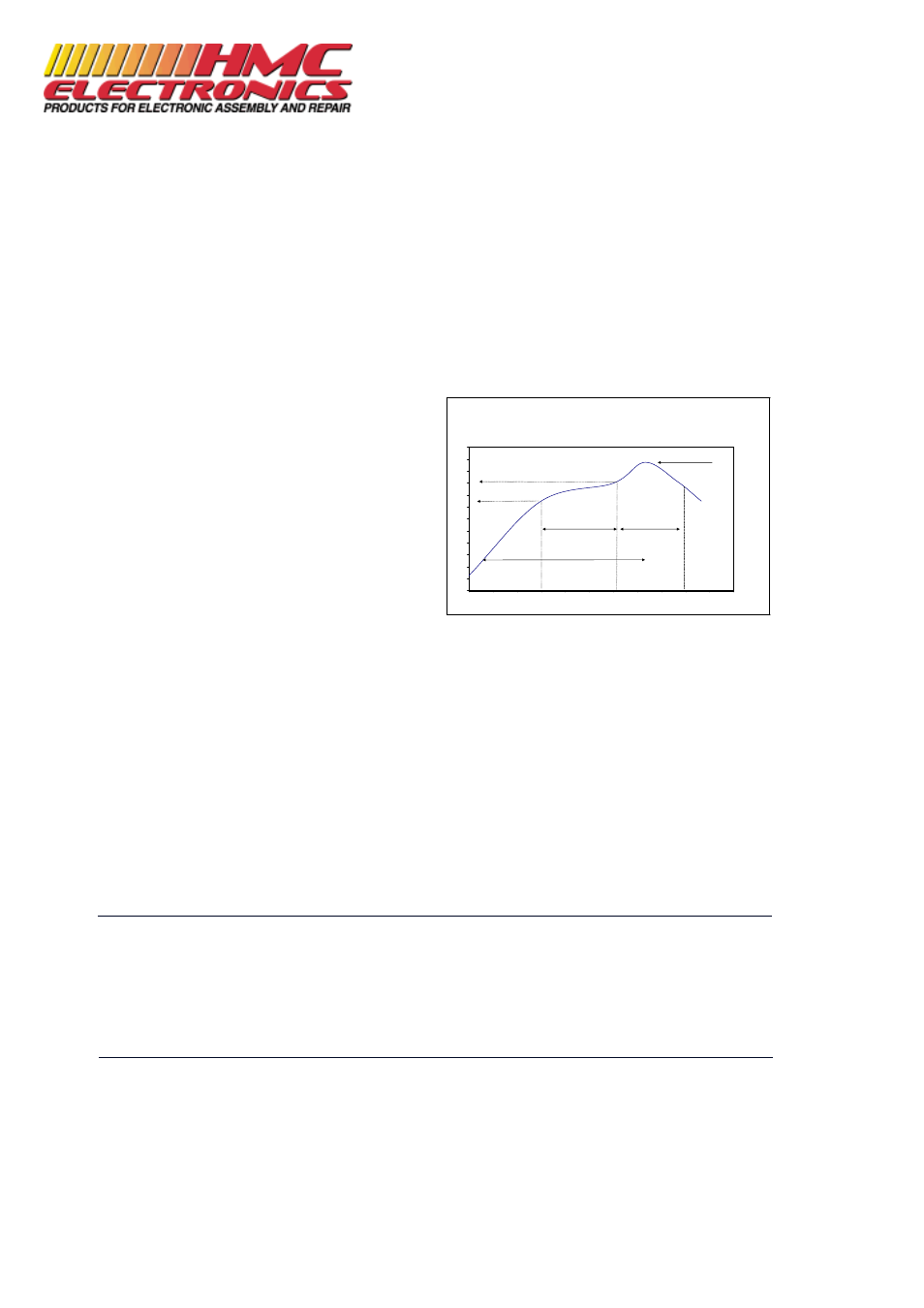

Recommended Reflow Profile:

The recommended reflow profile for R562 made with

either the Sn63Pb37 or Sn62Pb36Ag02 is shown

here. This profile is simply a guideline. Since R562 is

a highly active solder paste, it can solder effectively

over a wide range of profiles. Your optimal profile may

be different from the one shown based on your oven,

board and mix of defects. Please contact Kester if you

need additional profiling advice.

Cleaning:

R562 residues are best removed using automated cleaning equipment (in-line or batch) within 96 hours of

soldering. De-ionized water is recommended for the final rinse. Water temperatures should be 49-60°C

(120-140°F). Kester's 5768 Bio-Kleen

®

saponifier can also be used in a 1-2% ratio for aqueous cleaning

systems.

Storage, Handling, and Shelf Life:

Refrigeration is the recommended optimum storage condition for solderpaste to maintain consistent viscosity,

reflow characteristics and overall performance. R562 should be stabilized at room temperature prior to printing.

R562 should be kept at standard refrigeration conditions, 0-10°C (32-50°F). Please contact Kester if you

require additional advice with regard storage and handling of this material. Shelf life is 6 months from date

of manufacture when handled properly and held at 0-10°C (32-50°F).

Health & Safety:

This product, during handling or use, may be hazardous to health or the environment. Read the Material

Safety Data Sheet and warning label before using this product.

World Headquarters: 800 West Thorndale Avenue, Itasca, Illinois, 60143-1341 USA

Phone: (+1) 630-616-4000 • Email: [email protected] • Website: www.kester.com

Kester Reflow Profile

Alloy: Sn63Pb37 or Sn62Pb36Ag02

0

20

40

60

80

100

120

140

160

180

200

220

240

0

30

60

90

120

150

180

210

240

270

300

330

Time (sec.)

Temperature (C)

Time to Peak Temperature

3.5-5.0 min. typical

5.5 min max

Soaking Zone

(120 sec. max.)

30-60 sec. typical

Reflow Zone

45-75 sec. typical

Peak Temp.

210 - 225 C

<1.8 C/Sec

Asia Pacific Headquarters

500 Chai Chee Lane

Singapore 469024

(+65) 6449-1133

European Headquarters

Ganghoferstrasse 45

D-82216 Gernlinden

Germany

(+49) 8142-47850

Japanese Headquarters

20-11 Yokokawa 2-Chome

Sumida-Ku

Tokyo 130-0003 Japan

(+81) 3-3624-5351

The data recommendations presented are based on tests, which we consider reliable. Because Kester has no control over the conditions of use, we disclaim any responsibility connected with the

use of any of our products or the information presented. We advise that all chemical products be used only by or under the direction of technically qualified personnel who are aware of the poten-

tial hazards involved and the necessity for reasonable care in their handling. The technical information contained herein is consistent with the properties of this material but should not be used in

the preparation of specifications as it is intended for reference only. For assistance in preparing specifications, please contact your local Kester office for details.

R562

Rev: 21Sep09

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440