Specifi cations, Operating instructions – HMC Electronics ESL324P-ESD Delta Regis Electric Screwdriver, Push Start User Manual

Page 4

Page 4

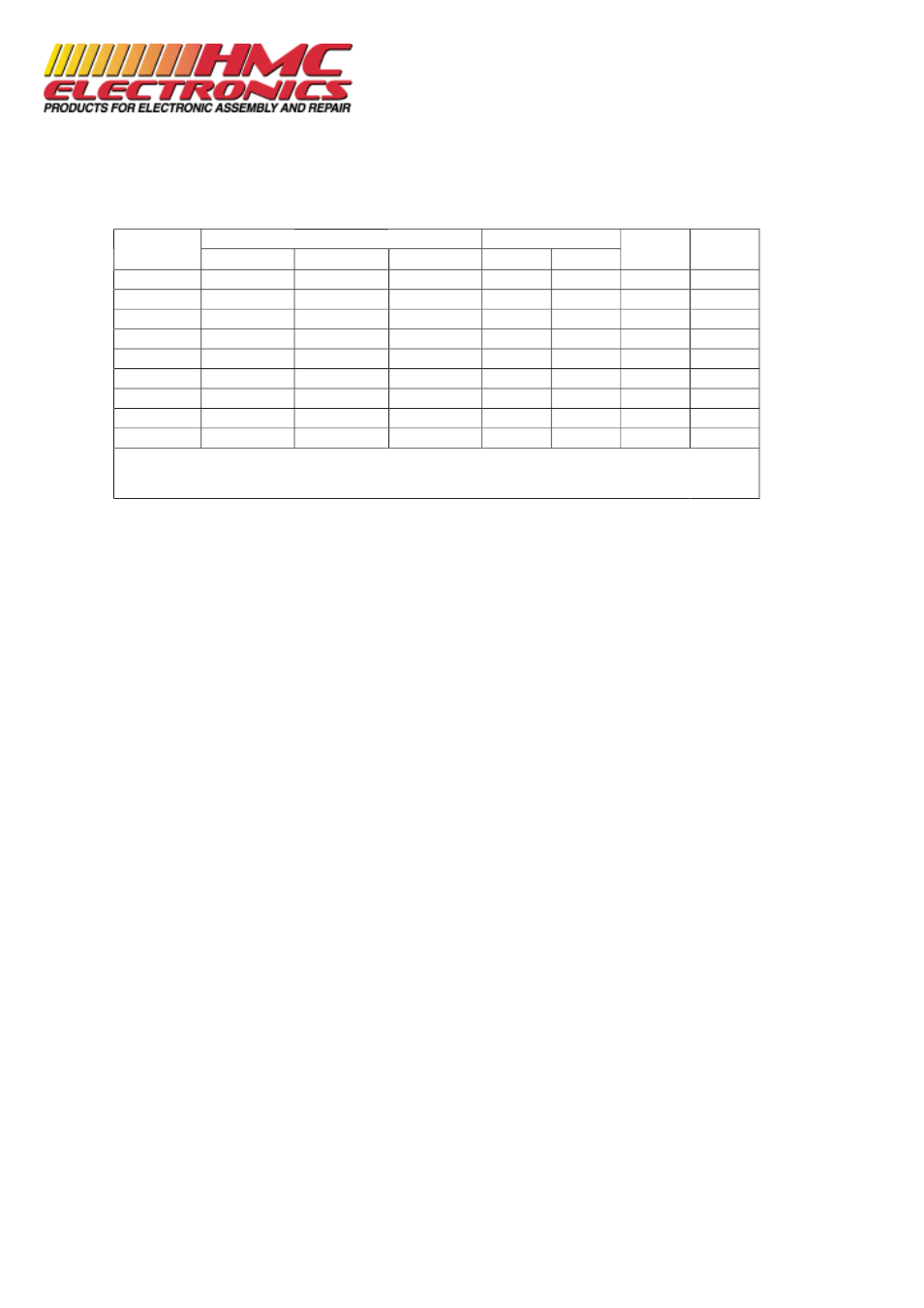

Specifi cations

Model

Torque

Speed (RPM)*

Weight

(gr)

Length

(mm)

in-lb

Nm

kgf-cm

Hi (32V)

Lo (20V)

ESL310-ESD

0.2 – 3.1

0.02 – 0.34

0.2 – 3.5

1000

600

270

205

ESL310S-ESD

0.2 – 3.1

0.02 – 0.34

0.2 – 3.5

500

350

270

205

ESL311-ESD

0.4 – 6.2

0.05 – 0.69

0.5 – 7

1000

600

270

205

ESL312-ESD

0.9 – 8.8

0.10 – 0.98

1 – 10

670

400

270

205

ESL323-ESD

1.5 – 10.6

0.17 – 1.2

1.7 – 12

1000

600

480

230

ESL324-ESD

3.0 – 14

0.34 – 1.58

3.5 - 16

1000

600

480

230

ESL327-ESD

6 - 21

0.69 - 2.37

6.9 - 24.2

750

450

600

260

ESL328-ESD

7 - 26.4

0.79 - 2.98

8.1 - 30.4

530

300

600

260

ESL329-ESD

14 - 42

1.6 - 4.7

17.3 - 47.9

530

300

700

269

Note:

• Specifi cations are applicable to push-start versions

• All models are intended for use with one of the following controllers: ECT300; ECT320; ECT345; ECT326*; ECT326V*

* RPM indicated is free speed based on using ECT326/326V Controller

Operating Instructions

Getting Started

• Connect the cord to the driver and power supply. Take care to align the key and the pins on the connectors.

• Plug the power supply/controller into the appropriate power outlet.

• Turn on the power supply/controller by pressing the power switch. Select the HI or LO speed via the speed selection

switch.

Installing Driver Bits

• Retract the sleeve on the bit holder.

• Insert the desired ¼” hex power bit.

• Release sleeve.

Recommended Grip

• It is recommended to grip the tool with the forefi nger on the trigger. This orientation allows the thumb to control

the forward/reverse switch. It also allows more contact between the operator’s palm and the tool – this is especially

important when operating at higher torques. The housing has been designed to conform to the operator’s hand in this

position.

Driving the Fastener

• Squeeze the trigger and hold until the clutch reacts and the tool shuts down.

• If using a push-to-start model, apply adequate downwards force to start the tool and hold until the clutch reacts and

the tool shuts down.

• The preset torque will not be reached if the trigger is released before the clutch activates.

• Ensure that enough downwards force is applied to prevent the screwdriver bit from camming out of the fastener.

Calibrating the Driver

• Torque is set by turning the torque adjusting nut on the nose of the driver.

• Torque is increased as the nut covers increasingly higher numbers on the scale.

• The numbers on the scale are for reference only and are not an indication of actual torque.

• Drivers should be calibrated on a torque tester suited for measuring the torque of power drivers. There should be a

rundown device that allows the driver to get up to speed and simulates the application’s actual joint characteristics

(ie. soft, medium, or hard joint).

Documentation Provided By HMC Electronics

33 Springdale Ave. Canton, MA 02021

(800) 482-4440