Gast VG-260-08-00 User Manual

Page 2

INSTALLATION and OPERATING INSTRUCTIONS for

PLASTIC MULTI-STAGED VACUUM GENERATORS

SAFETY

This is the safety alert symbol. When you see this symbol, per-

sonal injury is possible. The following signal words show the degree

of injury. Read the information carefully before proceeding.

DANGER

Severe personal injury or death will

occur if hazard is ignored.

WARNING

Severe personal injury or death can

occur if hazard is ignored.

CAUTION

Minor injury or property damage

can occur if hazard is ignored.

GENERAL INFORMATION

Ambient temperature for normal operation should not exceed

125

o

F (52

o

C). The low atmospheric pressure at high altitudes re-

duces performance of this unit. Materials used in the construction of

the vacuum generator include Delrin and Neoprene. If the unit will

see substances other than air, consult your local Gast representa-

tive for compatibility.

INSTALLATION

CAUTION Supply pressure regulated air to inlet of vacuum gen-

erator. Excess pressure can cause parts to burst.

1. The Gast vacuum generator may be mounted in any position

Mounting holes are provided in the aluminum head. Shock

mounting is not required. Round body area must not contact

any rigid frame to maintain alignment.

2. Connect a supply of clean, dry, regulated air to the inlet port in

the aluminum head. Regulator setting should be between

30 and 70 psig (2-5 bar). Best setting is 68 psig (4,6 bar). NO

LUBRICATION should be used with the Gast vacuum

generator.

3. The Gast vacuum generator has multiple inlet ports for con-

nection to the system to be evacuated. Unused ports

should be plugged. Connections to the system must be

equal or larger than the port. Smaller piping will cause lower

vacuum flows. Sealant should be used on all threads to prevent

leakage. Be sure to keep excess sealant from being drawn

into the vacuum generator. Dusty or dirty applications should

have a filter installed to prevent material from being drawn into

the generator. Gast filter AB665 is suggested.

WARNING Restriction of the exhaust air can cause the vacuum

port to become pressurized. Components not designed for full

line pressure can burst causing injury or death.

4. The exhaust port is located in the round end opposite the inlet

port. The muffler supplied should be attached to this port. DO

NOT RESTRICT the outlet of this muffler. This would reduce

both flow and maximum vacuum.

OPERATION

WARNING Solid or liquid material exiting the muffler outlet can

cause eye damage or skin cuts. Keep away from air stream.

To operate the vacuum generator, turn on the regulated air supply.

Air flowing through the unit causes vacuum to develop at the intake

ports. Material can enter the vacuum generator either in the com-

pressed air stream or at the vacuum port, it will be ejected through

the exhaust muffler.

Units with multiple stages contain valves which close as vacuum

levels increase. This gives higher flows at low vacuums, reducing

the amount of time required to evauate a system.

Adjust the regulator to 68 psig (4, 5 bar) for best vacuum genera-

tion. Block off vacuum line to check for maximum vacuum. Lower

than specified vacuum may be the result of system leaks. If this

condition appears, check and seal leaks.

SERVICING

CAUTION Shut off compressed air supply before servicing.

Parts may burst if air is on when unit is disassembled.

Your Gast vacuum generator requires no scheduled maintenance.

If performance drops, it may require cleaning. In most cases it is

not necessary to remove the vacuum generator from the system.

1. Turn off or disconnect air supply.

2. Remove muffler. Remove (2) nuts on the exhaust end of the

tie rods.

3. Slip aluminum tube off of round portion. Hold exhaust end in

place while removing tube.

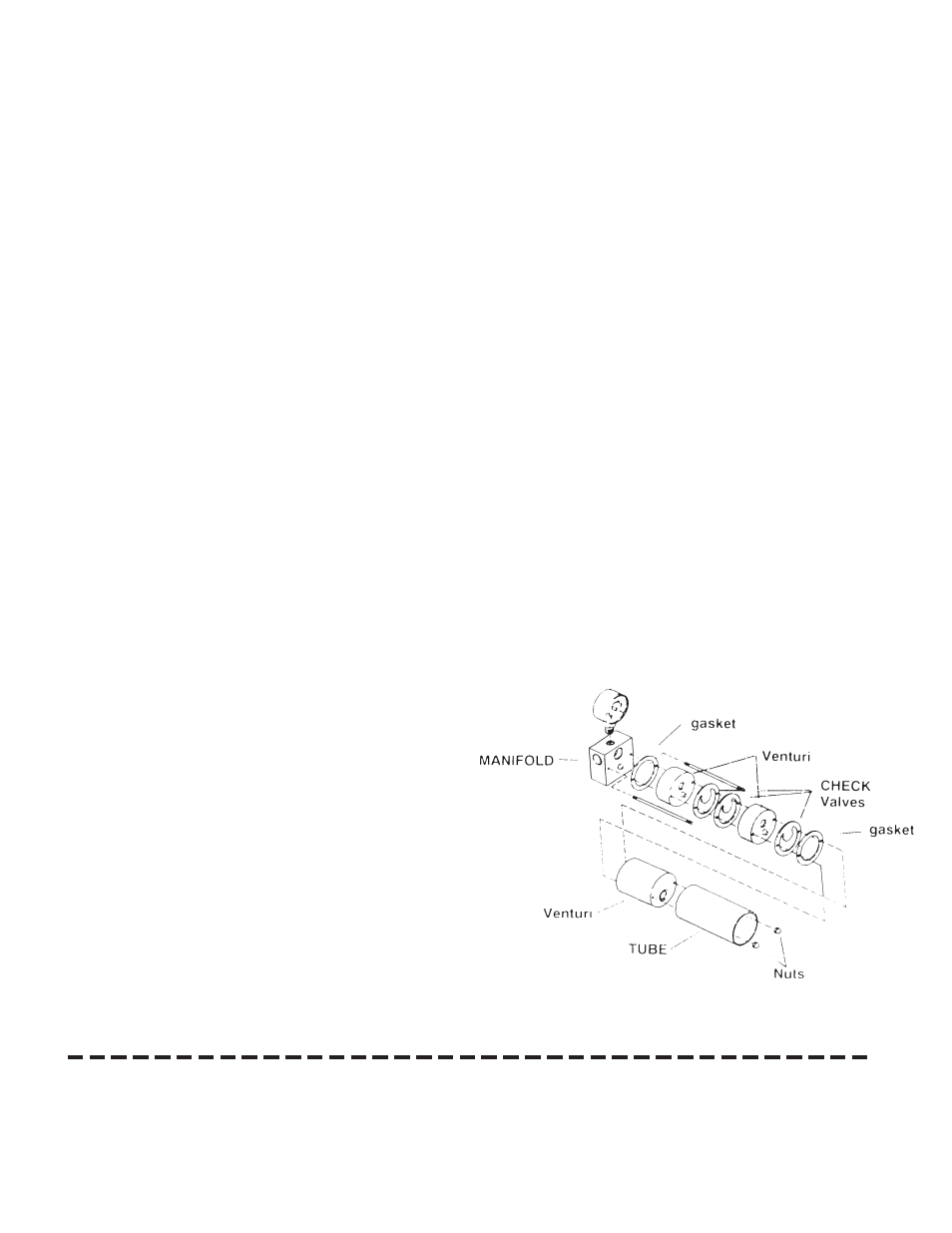

4. Remove each venturi stage and gaskets. Note the position of

each valve, gasket and venturi.

5. Remove any solid material and wash all parts in MILD DE-

TERGENT and WARM WATER to clean. Use of solvents

may damage parts.

6. If new gaskets and valves are required, use Gast Repair

Kit K549. Note not all parts included are required for each

model. Refer to drawing for proper installation.

7. Reassemble in reverse order. Torque nuts to 3in.-lb. (0,3 Nm).

.

Gast Manufacturing, Inc.

P.O. Box 97

2300 Highway M139

Benton Harbor, MI 49022

Ph: 269/926-6171

FAX: 269/925-8288

www.gastmfg.com

Gast Group Limited, United Kingdom

Unit 11, The I O Centre Nash Road

Redditch, B98 7AS

United Kingdom

ph: +44 (0) 1527 504040

Fax: +44 (0) 1527 525262

www.gastmfg.com

Gast Hong Kong

Unit 12, 21/F, Block B New Trade Plaza

6, On Ping Street, Shatin

N. T. Hong Kong

Ph: (852) 2690 1008

Fax: (852) 2690 1012

www.gasthk.com

We have Gast Certified Service Centers throughout the world. For the most up-to-date listing, contact one of our sales offices below: