Setting exercise time, Generator maintenanc, Setting exercise timer – Briggs & Stratton 40220 User Manual

Page 17: Generator maintenance, Wire connections, Before initial start-up, Recommended torque values, Generator ac connection system, Grounding the generator, Generator control circuit connection

INSTALLATION

17

WIRE CONNECTIONS

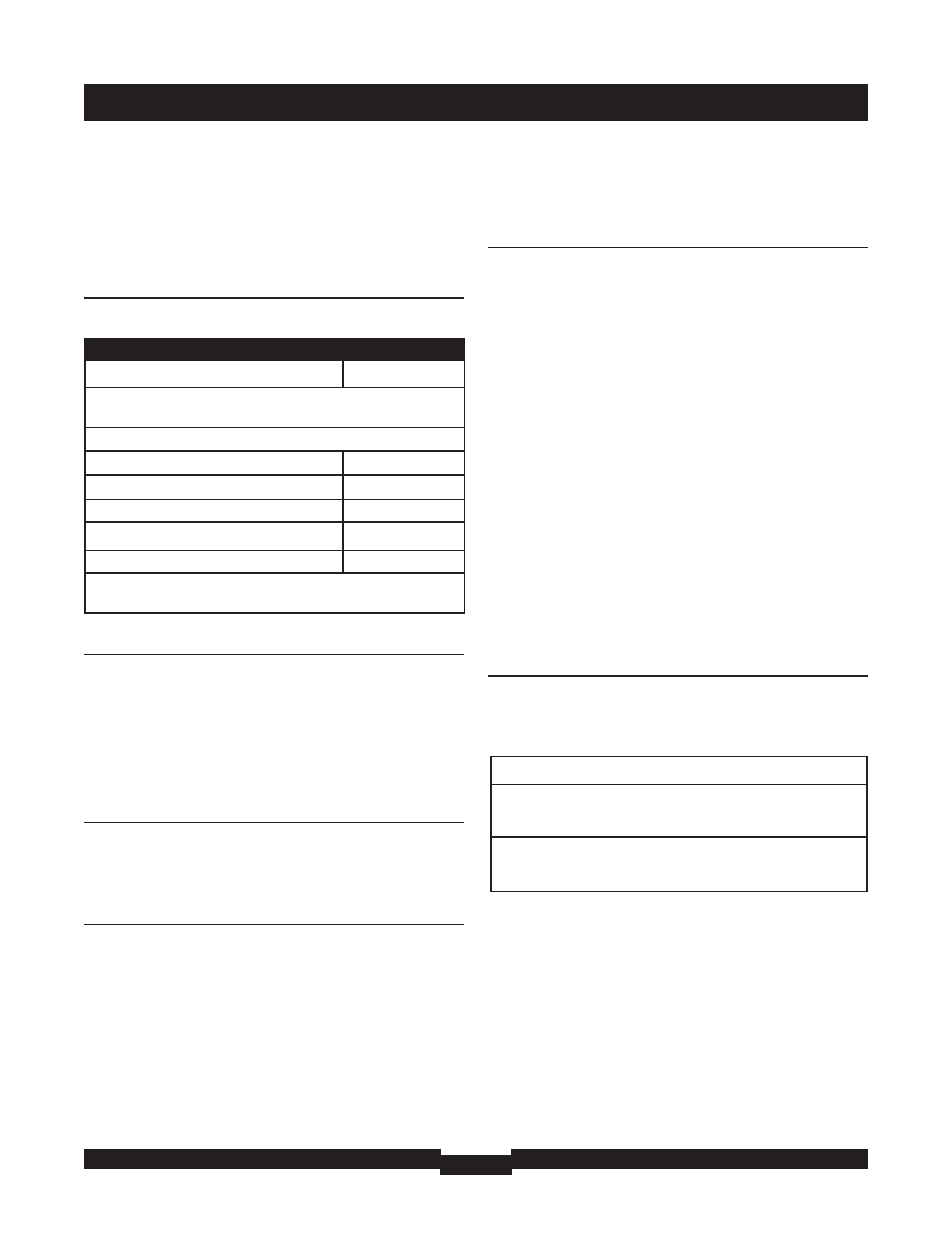

Recommended Torque Values

Torque all wire connections/fasteners to values recommended in

Figure 10. Suitable for copper wire of 60°/75°C rating.

Generator AC Connection System

A single-phase, three-wire AC connection system is used in

the Home Standby Generator. The stator assembly consists

of a pair of stationary windings with two leads brought out of

each winding. The junction of leads 22 and 33 forms the

neutral lead. A complete schematic and wiring diagram can

be found on pages 26-27.

NOTE: Neutral is not bonded to ground at generator.

Grounding the Generator

Ground the Home Generator System per applicable codes,

standards, and regulations. The GND lug is located in the

disconnect box.

Generator Control Circuit Connection

Control circuit interconnections consist of "240V AC Utility"

leads. These two leads must be routed in conduit. Control

lead functions are briefly described as follows:

• Leads deliver utility power to the generator’s circuit board,

optional battery warmer and oil heater and charge the

battery.

Using installer-supplied minimum 300V, 14 AWG copper

wire, connect control circuit terminals in the disconnect box

to the Transfer Switch.

Remote Diagnostic LED Plate

The light on the remote LED plate is referred to as the

Diagnostic LED. The LED will stay lit indicating the generator is

in ready mode and will turn on and off in a series of blinks if

certain faults are detected in the Home Standby Generator. A

mounting plate is supplied so that it can be installed at a

convenient indoor location. The owner will use it to observe

the status of the Home Standby Generator. Consult with the

owner for a convenient location.

To install the remote diagnostic LED plate:

• Mount installer-supplied electrical box to wall.

• Using installer-supplied wire, connect the remote LED

leads to the “Remote Status Light” in disconnect box.

NOTE: LED leads are polarity sensitive.

• Attach mounting plate to electrical box.

Refer to the section “Fault Detection System” on pages 21-22

for operation.

BEFORE INITIAL START-UP

Engine Oil

This engine is shipped from the factory filled with the

recommended oil. Before starting the engine, check oil level

and ensure that engine is serviced as described in the engine

operator’s manual.

Oil Considerations

Your Home Standby Generator is equipped with an engine

that has been pre-run at the factory and does not require the

traditional “break-in” procedure.

The generator is filled with synthetic oil (API SJ/CF 5W-

30W). This allows for generator operation in the widest range

of temperature and climate conditions.

NOTE: The use of synthetic oil DOES NOT alter the required

oil change intervals described in the engine operator’s

manual.

CONNECTIONS:

Torque Value

In Main Distribution Panel:

Refer to panel manufacturer specs

In Disconnect Box:

240V AC Utility

5 in-lb

Engine Start

5 in-lb

Remote Status

5 in-lb

Generator

17 in-lb

Ground

40 in-lb

Circuit Breakers:

Refer to circuit breaker manufacturer specs

Figure 10 — Recommended Torque Values

NOTICE

Any attempt to crank or start the engine before it has been

properly serviced with the recommended oil will result in

equipment failure.

• Refer to engine manual for oil fill information.

• Damage to equipment resulting from failure to follow this

instruction will void warranty.