C.b.s. scientific linear gradient maker 6, 2 components/assembly – C.B.S. Scientific GM-2000 User Manual

Page 6

C.B.S. Scientific

Linear Gradient Maker

6

Be sure that all gradient makers are secure either by attaching support rod to a ring stand or

mounting on a level surface.

SECTION 2

Description of Parts

2.1

Unpacking

Remove the gradient maker from the shipping container and place on a level surface in an

authorized area. Verify that the catalog number on the gradient maker matches the packing list.

Check for any damage which may have occurred during shipping. Contact C.B.S. Scientific

customer service immediately if any damage is found.

2.2 Components/Assembly

The gradient makers consist of the acrylic/teflon mixing chamber made either from a solid block

or tubing. Each gradient maker is supplied with an outflow control valve, which should be

attached to the male luer adapter on the side of the base.

SECTION 3

Instructions for Use

3.1

Gradient Maker Preparation

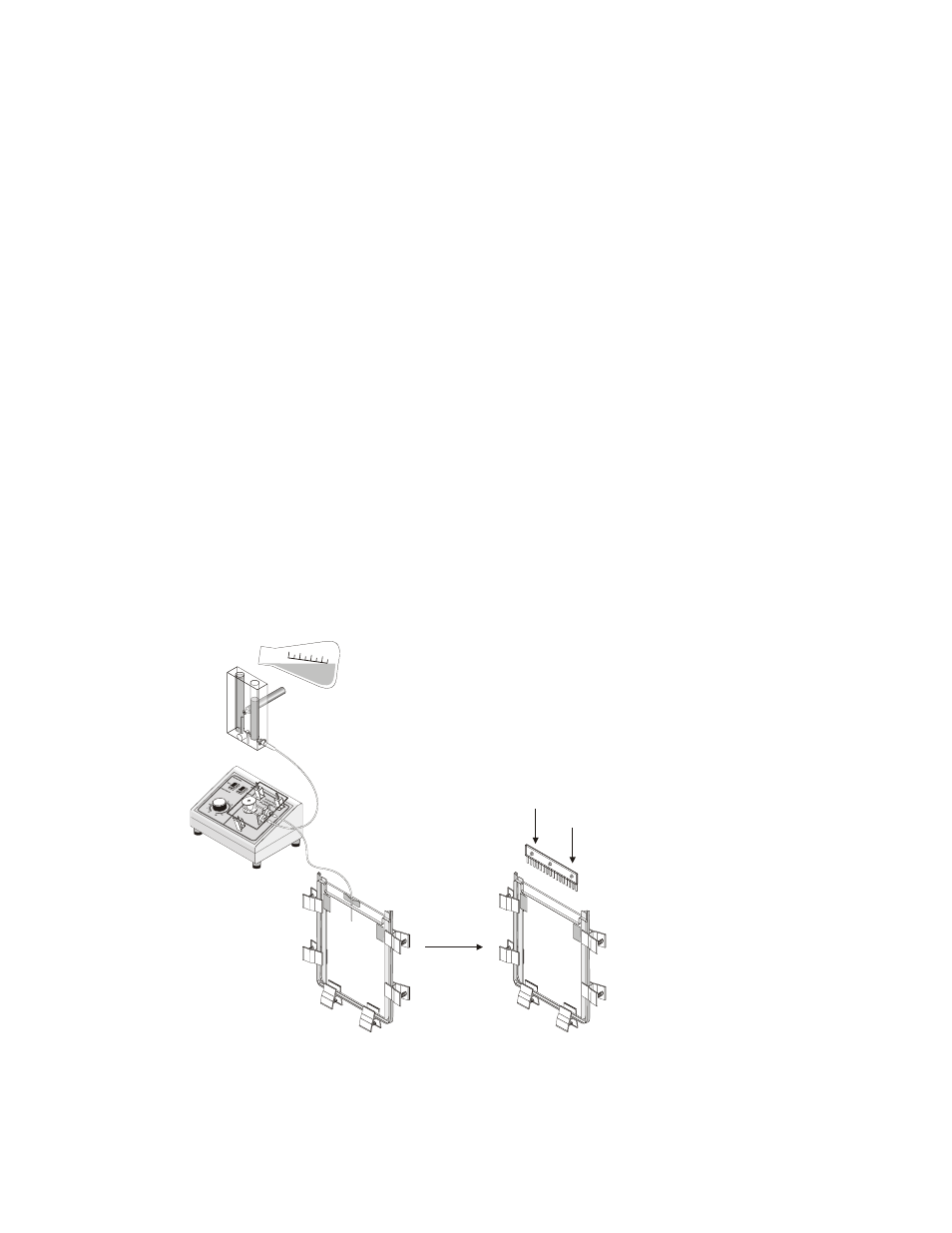

1. Prepare gel sandwich and gel solutions as described. See Figure 3 for general set-up of the

gel casting procedure.

Vertical Gradient Gel Casting using Gel Wrap,

GM-40 gradient former and mini-pump

Figure 3

1.

Assemble gel plate sandwich using Gel Wrap

®.

2.

Stand upright and level on two bottom casting clamps (GPC-0002).

3.

Pump desired gradient into plate sandwich at medium speed. (Determine optimal speed empirically.)

4.

Insert 16 well comb; allow time for polymerization.

5.

Rinse cassette with d.i. H

2

O. Remove comb.

6.

Transfer sandwich to gel cassette; use GPC-0001 spring clamp. Leave gel wrap in place.

7.

Displace bottom portion of Gel Wrap

® from plate to allow lower (anodal) buffer contact with gel.