Opl optical liquid level sensors – APG OPL datasheet User Manual

Page 3

3

Automation Products Group, Inc.

1025 West 1700 North

Tel. 1/888/525-7300

Logan, UT 84321 USA

Fax 1/435/753-7490

w w w . a p g s e n s o r s . c o m

s a l e s @ a p g s e n s o r s . c o m

OPL Optical Liquid Level Sensors

APG

Automation Products Group, Inc.

®

■

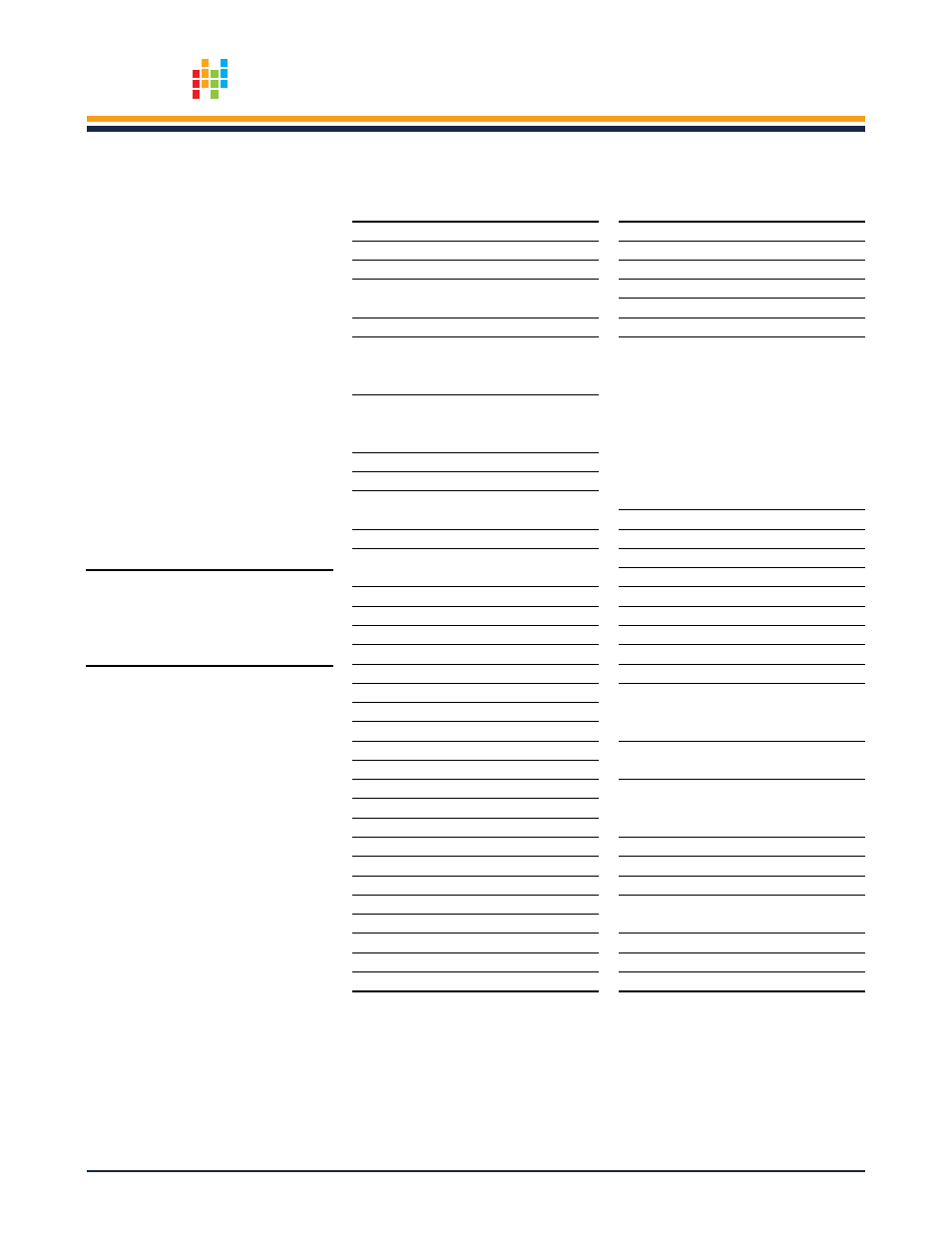

Corrosion Resistance Guide

Estel Body Material of

Optic Level Sensor and Thermistor

Level Sensor

This chart is intended as a general

guide and has been complied from

many sources believed to be reliable,

however, no guarantee is implied.

Because of the extensive scope

of this field, the tabulation is not

complete or conclusive. Corrosion

rates vary widely with concentration,

temperature and the presence of

abrasives. Impurities or other trace

elements common in industrial

liquids may inhibit or accelerate the

reaction of the material.

Key to Ratings:

A: No effect

Usable

B: Minor effect

Usable, but life my be

shorter than usual

C: Fair to poor

Do not use

D: Not recommended Do not use

Chemical

Rating

Acetic Acid

5%

B

Acetic Acid

10%

D

Acetone

C

Alcohols

Ethyl

A

Methyl

A

Aromatic Solvents

C

ASTM Motor Fuel

A

A

B

A

C

C

ASTM Ref Oil

#1

A

#2

A

#3

A

Beer

A

Benzene

C

Bleaching Liquors

5%

A

10%

C

Calcium Hydroxide

B

Calcium Hypochlorite

5%

A

10%

C

Calcium Oxide

B

Chlorine Water

D

Chlorine

D

Cider (Apple Juice)

B

Ethanol

A

Ethylene Glycol

A

Fatty Acid

B

Ferric Chloride

C

Ferrous Sulfate

B

Fruit Juice

B

Gasoline

A

Glucose (Corn Syrup)

B

Glue, P.V.A.

B

Glycerin

A

Grease

A

n-Hexane

C

Hydrochloric Acid

D

Hydrogen Peroxide

D

Jet Fuel/ASTM-A

D

Kerosene

A

Lubricant Oil

A

Chemical

Rating

Methanol

A

Methyl Ethyl Ketone

B

Methyl Isobutyl Ketone

B

Milk

A

Naphtha

B

Nitric Acid

D

Oils

Aniline

D

Castor

A

Corn

A

Diesel Fuel A

Fuel

A

Mineral

A

Silicone

A

Transmission A

Vegetable

A

Petroleum

B

Propane (LPG)

B

Propylene Glycol

A

Salt Brine (NaCl Saturated)

A

Sea Water

A

Soap Solutions

A

Sodium Carbonate

B

Sodium Bicarbonate

B

Sodium Chloride

A

Sodium Hydroxide

10%

A

20%

B

50%

D

Sodium Hypochlorite

20%

A

100%

D

Sulfuric Acid

10%

A

25%

B

50%

D

Toluene

C

Urea

B

Vinegar

C

Water

Fresh

A

Salt

A

Whiskey

B

Wine

A

Xylene

C

Specifications are subject to change without notice.

Immersion test conditions: 73°F (23°C) x 672 hours

The estel material is chemically similar to DuPont Hytrel® (Reg TME.I. DuPont de Nemours

& Co.)