Echo SG340 Instruction v.3 User Manual

Page 2

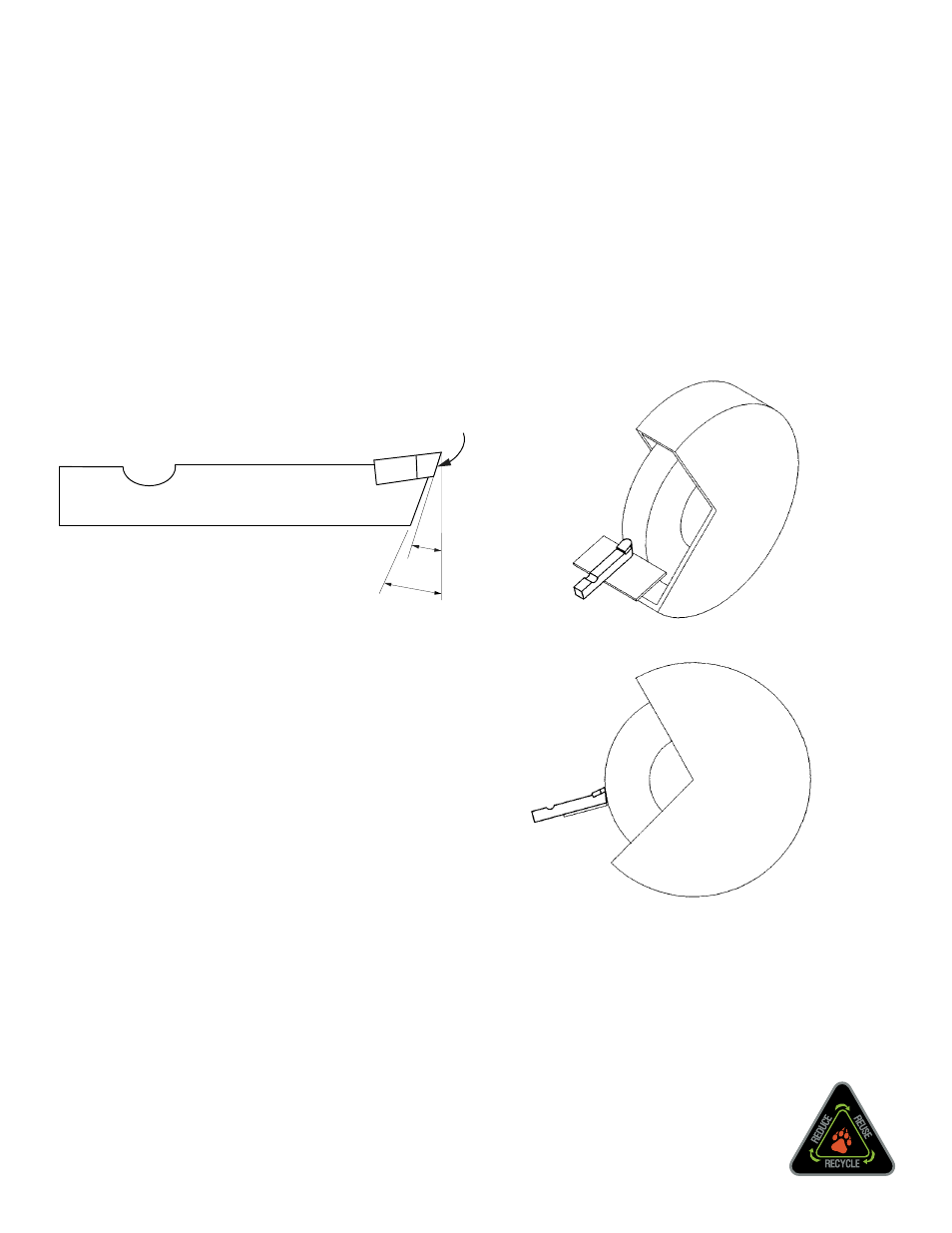

15°

11°

Sharpen

this surface

CUTTING TEETh MAINTENANCE

The carbide cutting teeth stay sharp for approximately two to

eight hours of operation. A person familiar with sharpening

carbide should use the following instructions to sharpen the

cutting teeth when they become dull.

Grind teeth to sharpen, maintaining original angles.

•

Duplicate all clearance and relief angles. The cutting

teeth last longer if the original contour of the tip is

maintained as closely as possible during grinding. Be

sure to leave adequate steel to support the carbide (see

below).

Dry grinding is suggested when sharpening to reduce

•

the chance of cracking from insufficient coolants. Dry

grinding also allows better visibility and longer wheel life

due to better grinding action control.

Use a silicon carbide grinding wheel for the carbide

•

portions of the teeth. Grinding the steel portions of the

teeth with a carbide wheel is possible, but the wheel

lasts longer if an aluminum oxide wheel is used for the

steel portions. The following wheels are recommended:

- Silicon carbide 60 grit for carbide.

- Aluminum oxide 24 grit for steel.

Move cutting teeth constantly when in contact with the

•

grinding wheel surface to reduce heat concentration,

which may damage the teeth. This method will reduce

uneven wheel wear. Refer to diagram below.

Never place the cutting teeth in water immediately after

•

grinding; the carbide tip may crack. Carbide is many

times harder than steel, but does not have the same

thermal characteristics.

EChO BEAR CAT

www.bearcatproducts.com

237 NW 12th Street, West Fargo, ND 58078-0849

Phone: 701.282.5520 • Toll Free: 800.247.7335 • Fax: 701.282.9522

E-mail: [email protected] • [email protected]