Maintenance and care, Emission data, Emission control – Echo EDR-210 User Manual

Page 13

11

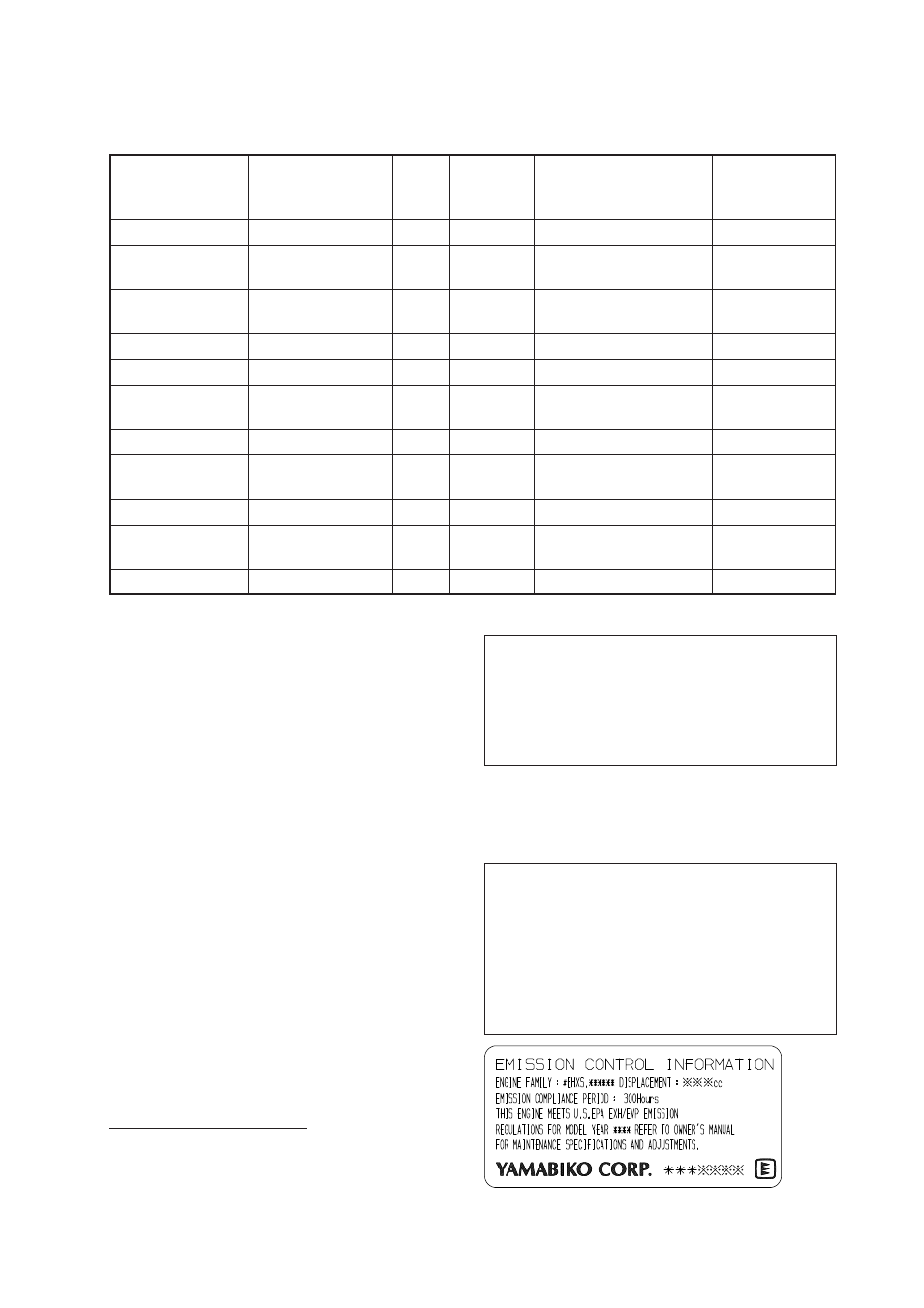

MAINTENANCE AND CARE

IMPORTANT

Time intervals are maximum. Actual use and

your experience will determine the frequency

of required maintenance.

Record dates of monthly and yearly

inspections.

AREA

MAINTENANCE

PAGE

BEFORE

MONTHLY

YEARLY

DATE

USE

MAINTENANCE

PERFORMED

Air Filter

Clean/Replace

13

•

Fuel Filter

Inspect/Clean/

13

•

Replace

Spark Plug

Inspect/Clean/

13

•

Adjust/Replace

Carburetor

Adjust

14

•

Cooling System

Inspect/Clean

15

•

Silencer

Inspect/Tighten/

Clean

15

•

Starter Rope

Inspect/Replace

-

•

Drills

Inspect/Clean/

-

•

Lubricate

Fuel Leaks

Inspect

13

•

Screws, Bolts and Inspect,

Nuts

Tighten/Replace

-

•

Fuel Line

Inspect

-

•

EMISSION DATA

EMISSION CONTROL

(EXHAUST and EVAPORATIVE)

EPA 2010 and Later and/or C.A.R.B. TIER III

The emission control system for the engine is EM

(engine modifi cation) and, if the second to last

character of the Engine Family on the Emission

Control Information label (sample below) is "C", "K",

or "T",the emission control system is EM and TWC

(3-way catalyst). The fuel tank/fuel line emission

control system is EVAP (evaporative emissions).

Evaporative emissions for California models may

only be applicable to fuel tanks.

An Emission Control Label is located on the

engine. (This is an example only, information on

label varies by engine family).

PRODUCT EMISSION DURABILITY

(EMISSION COMPLIANCE PERIOD)

The 300 hours emission compliance period is

the time span selected by the manufacturer

certifying the engine emissions output meets

applicable emissions regulations, provided that

approved maintenance procedures are followed

as listed in the Maintenance Section of this

manual.