11 trailer service tips, English – Echo CH4400 Owners Manual v.1 User Manual

Page 23

4 INCH CHIPPER

19

ENGLISH

SERVICE & MAINTENANCE

Before inspecting or servicing any part of this machine, shut off power source,

disconnect spark plug wire from spark plug and make sure all moving parts have come to a complete stop.

WARNING

InsTallInG THe new BearInGs

1. replace bearing and center in the bearing opening.

2. Tighten the two 1/2 x 1-1/2” carriage bolts and 1/2”

centerlock nuts securing the rear bearing to the chipper

housing. Torque to 75 ft-lb.

3. Slide the rotor back into the chipper housing.

4. Slide a snap ring onto the rotor shaft, making sure that

it is seated properly on the rotor.

5. Slide the bearing shim, front bearing and second snap

ring on the rotor, making sure that the second snap ring

is seated properly on the rotor.

6. Reinstall the disk cover using seven 5/16” nuts and

washers.

7. Next, the rotor must be centered vertically and

horizontally inside the chipper housing. To do this,

measure the distance from the rotor to the inside edge

of the chipper housing at four points around the disk.

Adjust the rotor until all four points are an equal distance

from the edge of the chipper housing or use Alignment

Tool 76302-12. Finish tightening the 1/2 x 3/4” bolts and

nuts securing the front bearing to the chipper housing

to a torque of 75ft-lbs.

8. Tighten the two set screws located on both the front

and rear bearings, securing the bearings to the rotor

shaft. Torque set screws to 160 inch-lbs.

9. Slide the bushing and sheave onto the shaft.

10. Tighten the two 1/2 x 3/4” bolts and nuts securing the

front bearing to the chipper housing. Torque to 75 ft-

lbs.

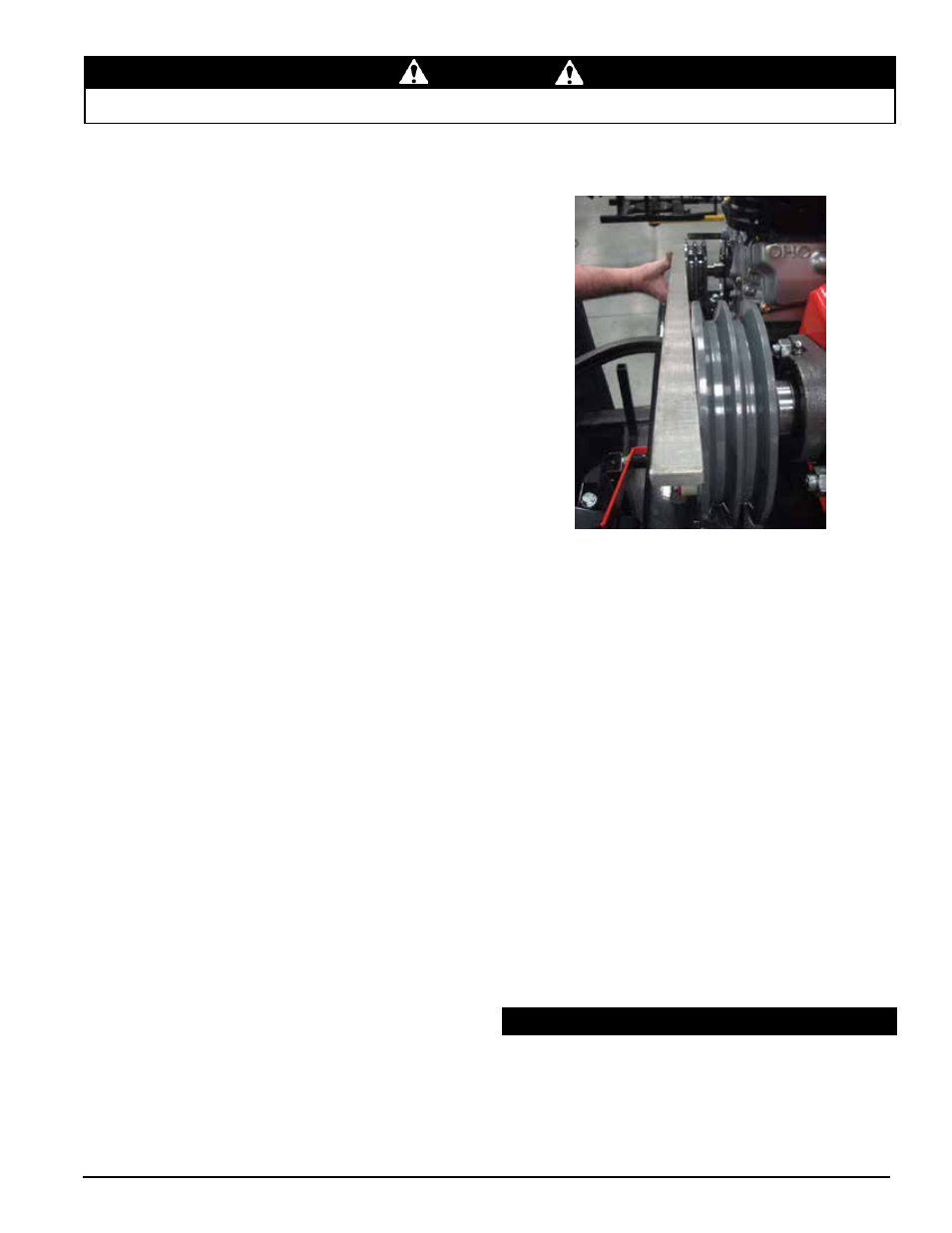

11. using a straight edge, align the sheave with the other

pulley to ±1/16”. Keep in mind that the sheave will shift

approximately 1/16” to 1/8” away from you once it is

tightened (see Figure 5.7).

12. Insure the pulley drive key is completely seated under

the pulley and tighten the set screw.

13. remove the three screws in the sheave and put them in

the other three threaded holes on the sheave. Tighten

the screws equally until the bushing tightens. Torque

to 108 inch-lbs.

5.11 TraIler servICe TIps

1. Check wheel bolt torque monthly.

2. Check air pressure in tires monthly.

3. Check and repack wheel bearings with grease every

12 months.

4. When towing, always connect the safety chains. Make

sure trailer hitch bolts are tight.

5. Check trailer lights periodically.

14. Recheck pulley alignment. Pulley faces should line

up. If not, readjust and repeat alignment check (see

Figure 5.7).

15. replace the belt.

16. Adjust the drive belt so that the belt deflection is 7/16”

when a 20 lb. load is placed against the belt (see

Figure 5.6). To do this, adjust both 5/16” adjustment

bolts equally.

17. If the bolts and nuts between the engine plate and the

trailer cannot be adjusted any further, and the tension

needs further adjustment, tighten the eyebolt until the

appropriate deflection is achieved.

18. Once correct belt deflection has been achieved, tighten

both 5/16” flange nuts to maintain it.

19. Tighten the four carriage bolts attaching the engine

plate to the trailer.

20. reinstall the belt guide.

21. The chipper engagement lever should be in the START

position (up).

22. Reinstall the idler assembly.

23. Attach the chipper chute to the disk cover.

24. attach the discharge cap.

25. replace the belt guards.

5.7 checking pulley alignment

Remove the disk cover.

9b. loosen the set screws securing the back bearing

to the rotor shaft.

9c. Remove the two 1/2 x 1-1/2" bolts and 1/2"

centerlock nuts holding the back bearing to the

chipper housing.

9d. Slide the chipper disk out from the chipper housing

until the bearing slides off the rotor shaft.