3 operating the chipper (cont.), 4 feed roller control bar, Warning – Echo 74554 Owners Manual v.4 User Manual

Page 14

10

5 INCH CHIpper

OPERATION

The machine chips a variety of materials into a more

readily decomposed or handled condition. The following

guidelines will help you get started.

run unit at full operating speed

1.

before starting to

chip material.

limbs fed in to the chipper chute must be 5 inches

2.

(12 cm) in diameter or less. Trim side branches that

cannot be bent enough to feed into the chipper chute.

hold small diameter branches together in a bundle and

feed in simultaneously.

exclude pieces of metal, rocks, bottles, cans, and

3.

other foreign objects when feeding material into the

machine.

feed brush from the side of the chipper chute

4.

, rather

than from the front. Step aside to avoid being hit by the

brush moving into the chipper.

Place limb, butt end first, into the chipper chute

5.

until it contacts the chipper blades. The actual feed

rate of the limb into the chipper will depend on the type

of material fed and sharpness of the cutting blades.

if the engine slows to where it may stall

6.

, stop feeding

material and allow the engine to recover. Feed material

more evenly.

if the chipper jams,

7.

remove the branch and rotate it

before reinserting it into the chute. Alternately insert

and retract the limb or insert continuously at a rate that

will not kill the engine.

do not use the clutch to clear a plugged rotor.

8.

This

may cause belt damage. Refer to the instructions for

clearing a plugged rotor in the Service and Maintenance

section.

alternate greener material with dry material

9.

to

lubricate the chipping blades for longer life and better

performance. Chipping dead, dry material will create

heat and dull the chipping blades quickly.

sharpen the chipping blades periodically.

10.

Check

the sharpness of the blades every 5-15 hours. Refer

to the Service and Maintenance section for sharpening

instructions.

4.3 oPeraTing THe CHiPPer (ConT.)

To prevent personal injury or property damage: shut

off engine and make sure that all moving parts have

come to a complete stop before servicing, adjusting,

or repairing machine. disconnect the battery and

remove ignition key where applicable.

Warning

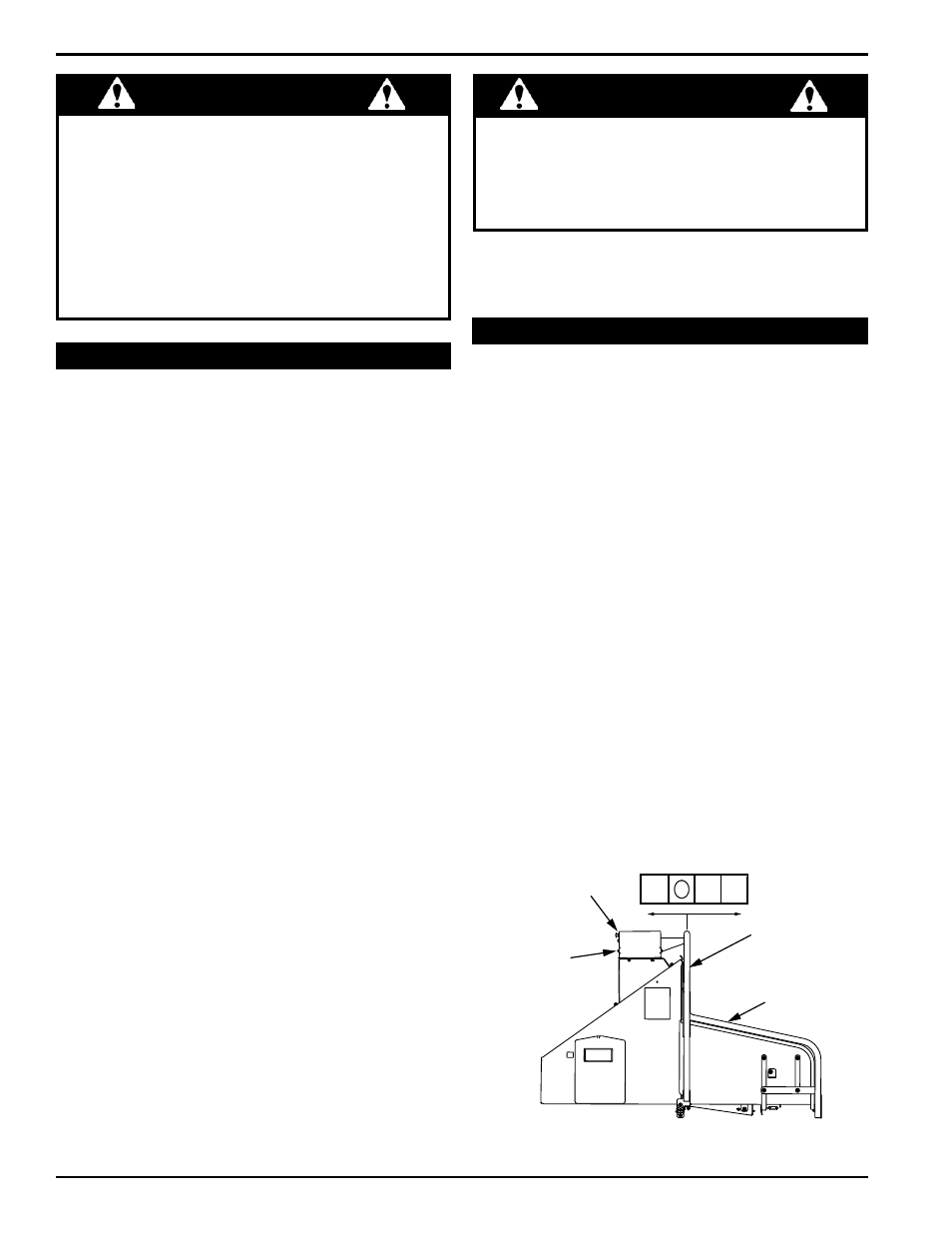

feed roller Control bar is used to manually control the

direction of the feed roller rotation.

Move the feed roller bar to FORWARd (F) when you want

the materials to feed into the chipper.

Move the feed roller bar to REvERSE (R) when you want

the chipper push materials back out of the feed chute

(when materials become jammed).

Move the feed roller bar to STOP to halt the rotation of the

feed roller.

4.4 feed roller ConTrol bar

Push the safety bar (euro models only) in the event of

an emergency and forward feed will stop. Push the reset/

override button to resume forward feed.

upon start-up, the safety bar light will be on. Push the

reset/override button to begin operating the feed roller.

if false trips occur, the reset button can be held in to

override the system.

The safety bar will lock into travel position. Place the

extension tray in an upright position. Push the safety bar

down to lock the bar. To unlock, lower the extension tray

and push in the safety bar. This will release the flange and

allow the safety bar to move freely.

R

REVERSE

R

F

FORWARD

STOP

REVERSE

Reset/Override

Button (where

available)

Safety Bar

Indicator

(where

available)

Feed Roller

Control Bar

Safety Bar

(where

available)

Warning

never lean over the chipper chute to push objects into the

cutting device. Use a push stick or brush paddle.

never use shovels or forks to feed brush. They can

cause extensive damage if they contact the blades.

In addition, metal pieces can be ejected from the

chipper chute and cause serious injury or death.

never feed brush into the chute with your feet.

never use hands or feet to clear materials that build up in

the chute.