8 clearing a plugged disk, 9 trailer service tips, 10 drive belts – Echo CH8993H Owners Manual v.6 User Manual

Page 23: Warning, English

19

8 INCH TURNTABLE CHIPPER

ENGLISH

SERVICE & MAINTENANCE

Before inspecting or servicing any part of this machine, shut off power source,

disengage the hydraulics, open shield and make sure all moving parts have come to a complete stop.

WARNING

5.9 Trailer service TiPs

5.8 clearinG a PluGGeD DisK

If the machine becomes plugged, lift the engagement

handle, shut off the engine, disconnect the spark plug

wire and allow the machine to come to a complete

stop before clearing debris. Do not operate the ma-

chine without proper guards and shields in place.

warninG

Feeding too large or too much material at once may plug

the chipper. To clear a plugged disk, proceed as follows:

1. lift the engagement handle and turn off engine key switch.

allow all moving parts to come to a complete stop.

2. remove the two 3/8" retaining bolts holding the access

cover to the chipper frame and lift up access cover.

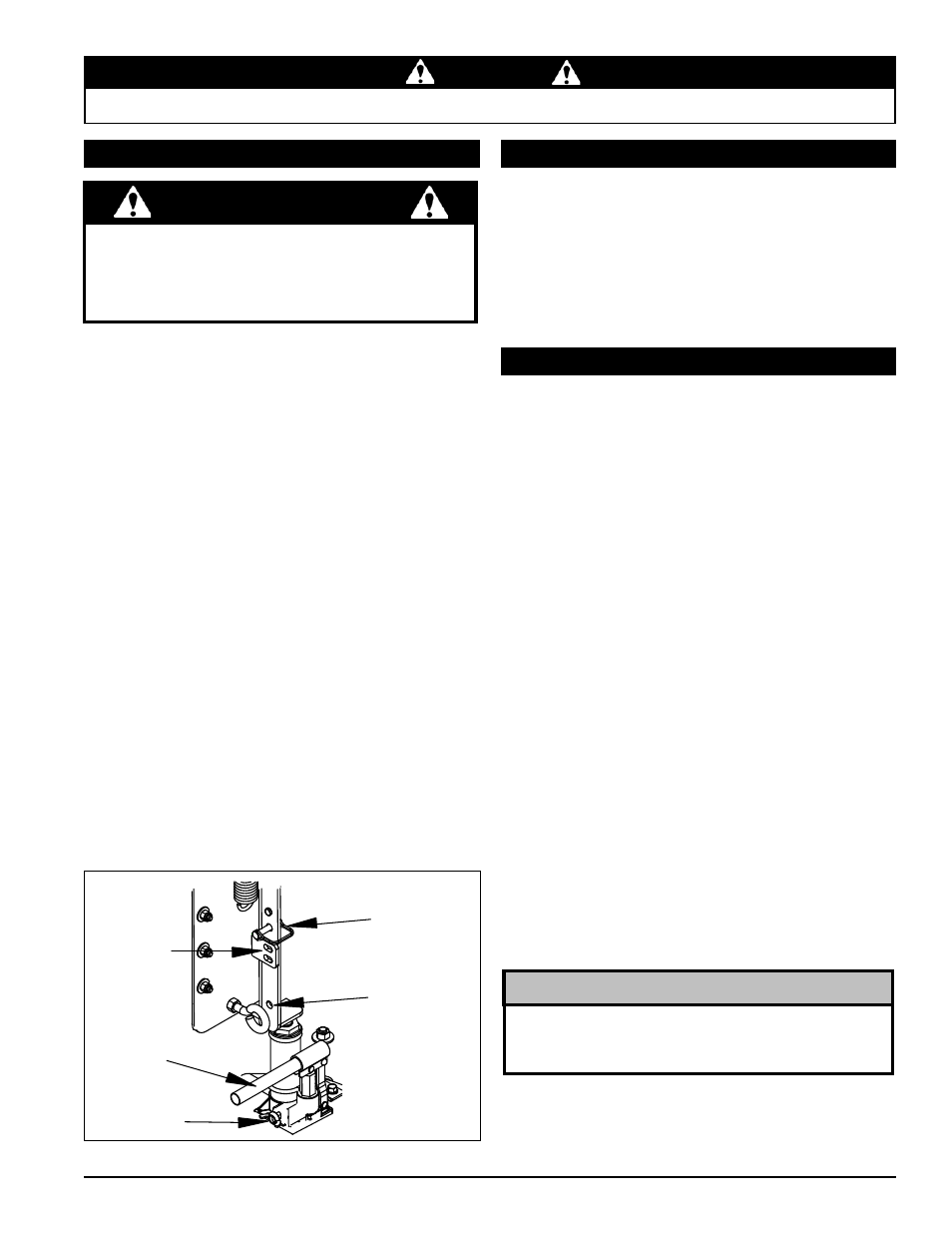

3. Remove the lock pin from storage position (see below).

4. Turn check valve clockwise to engage the jack pump.

5. Pump the handle to raise the feed roller until the lock pin

position aligns with one of the support bracket holes.

6. Secure the position by putting the lock pin through the

support bracket and lock pin position.

7. Clean the debris away from the chipper disk. Turn the disk

by hand to be sure it is free to rotate. Be careful to avoid

the chipper blades when cleaning out the debris.

8. remove the lock pin and put it back in storage

position. lEAVINg THE lOCK PIN IN ANy OTHER

POSITION MAy INTERFERE WITH FEED ROllER

OPERATION.

9. turn the check valve counterclockwise to disengage

the pump and lower the jack.

10. Close access cover and replace bolts.

11. Start the engine. lower the engagement handle

when engine is running to engage drive belt. resume

operation at 1/4 throttle.

LOCK PIN IN

STORAGE

POSITION

LOCK PIN

POSITION

SUPPORT

BRACKET

FEED

ROLLER

JACK

CHECK

VALVE

Figure 5.4, Feed Roller Jack

5.10 Drive BelTs

5.10.1 rePlacinG DisK Drive BelT

Check the condition of the drive belt annually or after ev-

ery 25 hours of operation, whichever comes first. If the

belt is cracked, frayed, worn or stretched, replace it. Re-

place belt with original banded type belt only. Do not use

single type belts.

1. lift engagement handle to disengage drive belt.

2. loosen bolt on engine tie. DO NOT REMOVE.

3. loosen the bolts securing the belt kicker to the

engine (located above the small sheave). DO NOT

REMOVE.

4. assure the belt tensioning bolts on the engine mount

plate are tight against the engine mount.

5. Turn each of the two bolts eight revolutions

counterclockwise.

6. loosen the four engine mount bolts and slide engine

towards chipper housing.

7. Remove the large idler pulley.

8. using a wrench, pull the small idler pulley away from

the hydraulic belt to release the tension.

9. Remove the hydraulic drive belt from the drive pulley

on the engine.

10. remove the old disk drive belt and install new disk drive

belt on engine and large pulley.

11. Install large idler pulley

12. lower engagement handle to engage drive belt

If belt does not easily install, turn the two belt tension

bolts counterclockwise an equal number of turns and

slide engine closer to chipper until belt can be installed.

noTe

1. Check wheel bolt torque monthly.

2. Check air pressure in tires monthly.

3. Check and repack wheel bearings with grease every

12 months.

4. When towing, always connect the safety chains. Make

sure trailer hitch bolts are tight.

5. Check trailer lights periodically.