2 am-se - straddle extension kit - installation, Description, Straddle adaptor wiring kit components – JLG 41EL Operator Manual User Manual

Page 44: Straddle adaptor wiring installation, Am-se - straddle extension kit – installation -2

SECTION 5 - OPTIONAL EQUIPMENT

5-2

– JLG Lift –

3120781

5.2

AM-SE - STRADDLE EXTENSION KIT –

INSTALLATION

Description

This sub-section contains instructions for installation of

the straddle extension adaptor to AM/EL Series, AC and

DC machines. Also included are instructions for set-up

and operation of the straddle extension kit.

The AM-SE straddle extension kit increases the versatility

of the AM/EL Series by providing a bridge for access to

areas where obstacles such as rows of seats, machines,

counters or stairwells are encountered. The double-winch

elevating system permits one man setup and swivel cast-

ers allow the coupled configuration to be easily maneu-

vered. The unit can be quickly disassembled for compact

storage.

The straddle extension provides clearance of up to 48

inches (1.2m) and the length for caster spacing is adjust-

able from 104 to 128 inches (2.6m to 3.3 m). The AM/EL

Series machines are fully operational at full rated capacity

when used in combination with the straddle extension.

Straddle Adaptor Wiring Kit Components

The straddle wiring kit for both the AM/EL Series includes

the following parts:

1.

Two (2) short wiring harness’ each with a female,

three (3) prong (twist-lock) connector on one end.

These will be wired together and into the existing

harness with three (3) 16 gauge wires - Red, White

and Green - exposed ready for connection.

2.

Two (2) Spring Clips.

3.

Four (4) #10-24 x .625 long bolts, nuts and lock-

washers.

4.

Two (2) 3/8" I.D.\ 1/2" O.D grommets.

Straddle Adaptor Wiring Installation

1.

Set up machine, i.e. install outriggers and level

machine. From outside raise platform as high as

possible to allow access to the wiring on the outrig-

ger interlock relay attached to the back of the center

crossmember on the base frame and also to install

the spring clips which hold the three prong twist-

lock plugs.

NEVER WORK UNDER AN ELEVATED PLATFORM UNTIL PLAT-

FORM HAS BEEN SAFELY RESTRAINED FROM ANY MOVEMENT

BY BLOCKING OR OVERHEAD SLING.

2.

Place a floor jack or other suitable support between

the mast and floor before working underneath plat-

form.

ON AC MACHINES UNPLUG THE POWER CORD, DC POWERED

MACHINES DISCONNECT THE MAIN POWER SUPPLY CONNEC-

TOR ON THE SIDE OF THE BATTERY STORAGE/CHARGER BOX.

THIS WILL PREVENT ANY POSSIBILITY OF GROUNDING ELEC-

TRICAL CIRCUIT AND CAUSING DAMAGE TO UNIT WHILE WORK-

ING AROUND ELECTRICAL COMPONENTS

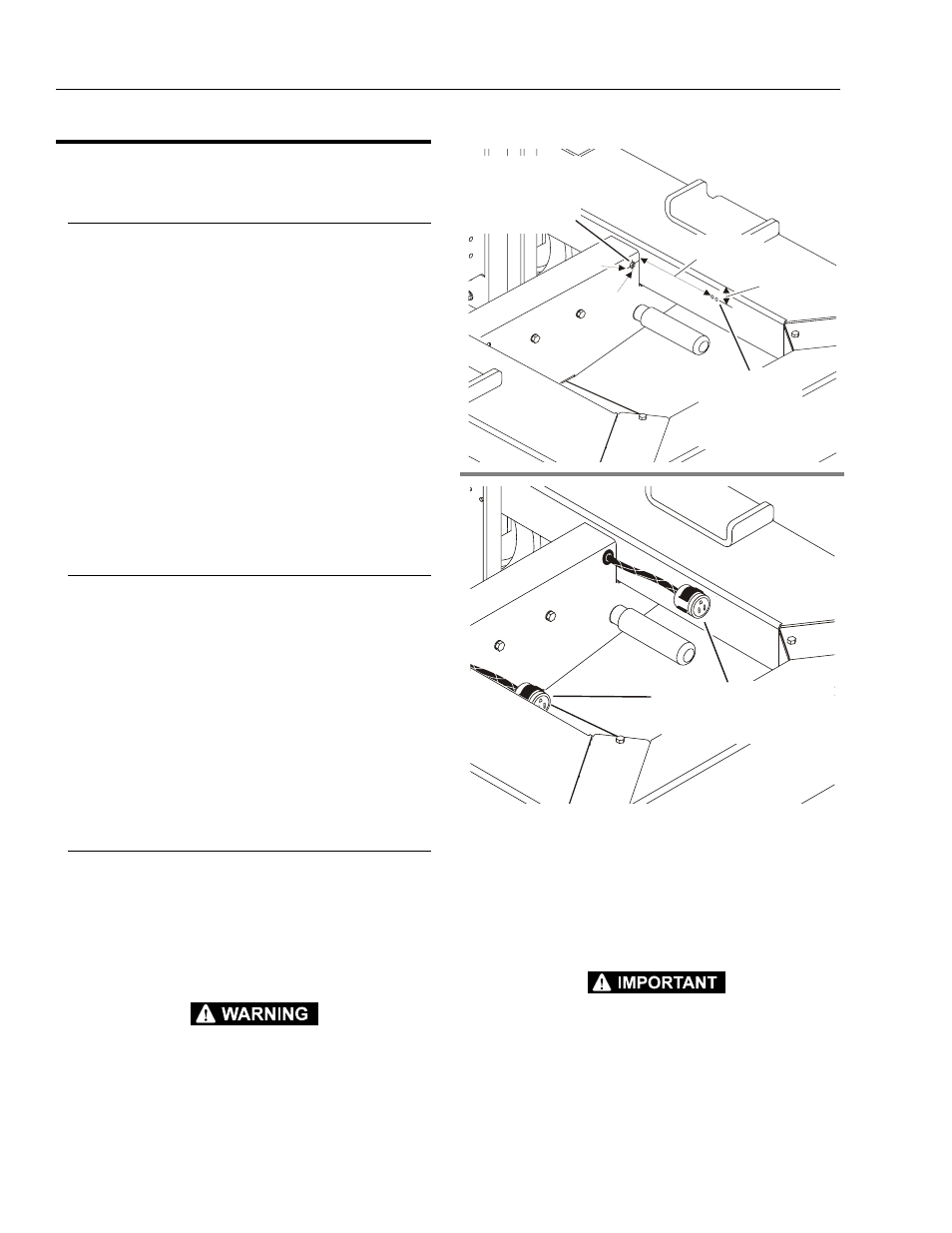

Figure 5-1. SE-Adapter - Wiring Kit

Hole Locations for Grommet & Spring Clips

(Same For Both Sides)

1"

3/4"

6-1/4"

HOLE FOR

WIRING

GROMMET

HOLES FOR

SPRING

CLIP

1-9/16"

ADAPTER WIRING PLUGS

(SHOWN MOUNTED)