Steer cylinder, Steer linkage, Front spindle assemblies – JLG 2658E3 ANSI Operator Manual User Manual

Page 14: Control boxes (platform and ground), Batteries, Motor/pump unit and valves, Platform placards, 4 daily walk-around inspection, Overall cleanliness, Placards

SECTION 2 - MACHINE PREPARATION AND INSPECTION

2-2

– JLG Sizzor –

3120761

Steer Cylinder

No rust, nicks, scratches or foreign material on piston rod;

no leakage.

Steer Linkage

No loose or missing parts; no visible damage.

Front Spindle Assemblies

No excessive wear; no damage; evidence of proper lubri-

cation.

Control Boxes (Platform and Ground)

Switches operable; no visible damage; placards secure

and legible; controller operable; no visible damage.

Batteries

Proper electrolyte level; cable connections tight; no visible

damage; no corrosion at battery cable connections.

Ensure batteries are fully charged.

Motor/Pump Unit and Valves

No leakage; units secure.

Platform Placards

No visible damage; placards secure and legible.

2.4 DAILY WALK-AROUND INSPECTION

It is the users responsibility to inspect the machine before

the start of each workday. It is recommended that each

user inspect the machine before operation, even if the

machine has already been put into service under another

user. This Daily Walk-Around Inspection, Figure 2-2, is the

preferred method of inspection.

In addition to the Daily Walk-Around Inspection, be sure to

include the following as part of the daily inspection:

Overall Cleanliness

Check all standing surfaces for oil, fuel and hydraulic oil

spillage and foreign objects. Ensure overall cleanliness.

Placards

Keep all information and operating placards clean and

unobstructed. Cover when spray painting or shot blasting

to protect legibility.

Operators and Safety Manual

Ensure a copy of this manual is enclosed in the manual

storage box.

Machine Log

Ensure a machine operating record or log is kept. Check

to see that it is current and that no entries have been left

uncleared, leaving machine in an unsafe condition for

operation.

Daily Lubrication

For those items pointed out in the Daily Walk-Around

Inspection requiring daily lubrication, refer to the Lubrica-

tion Chart for specific requirements.

2.5 DAILY FUNCTIONAL CHECK

Perform functional checks in accordance with the Daily

Functional Check before attempting to operate the

machine.

TO AVOID INJURY DO NOT OPERATE A MACHINE UNTIL ALL

MALFUNCTIONS HAVE BEEN CORRECTED. USE OF A MALFUNC-

TIONING MACHINE IS A SAFETY VIOLATION.

A functional check of all systems should be performed,

under no load, once the walk-around inspection is com-

plete, in an area free of overhead and ground level

obstructions. Perform pre-load functional check in accor-

dance with the following procedure:

1. Ensure batteries are fully charged.

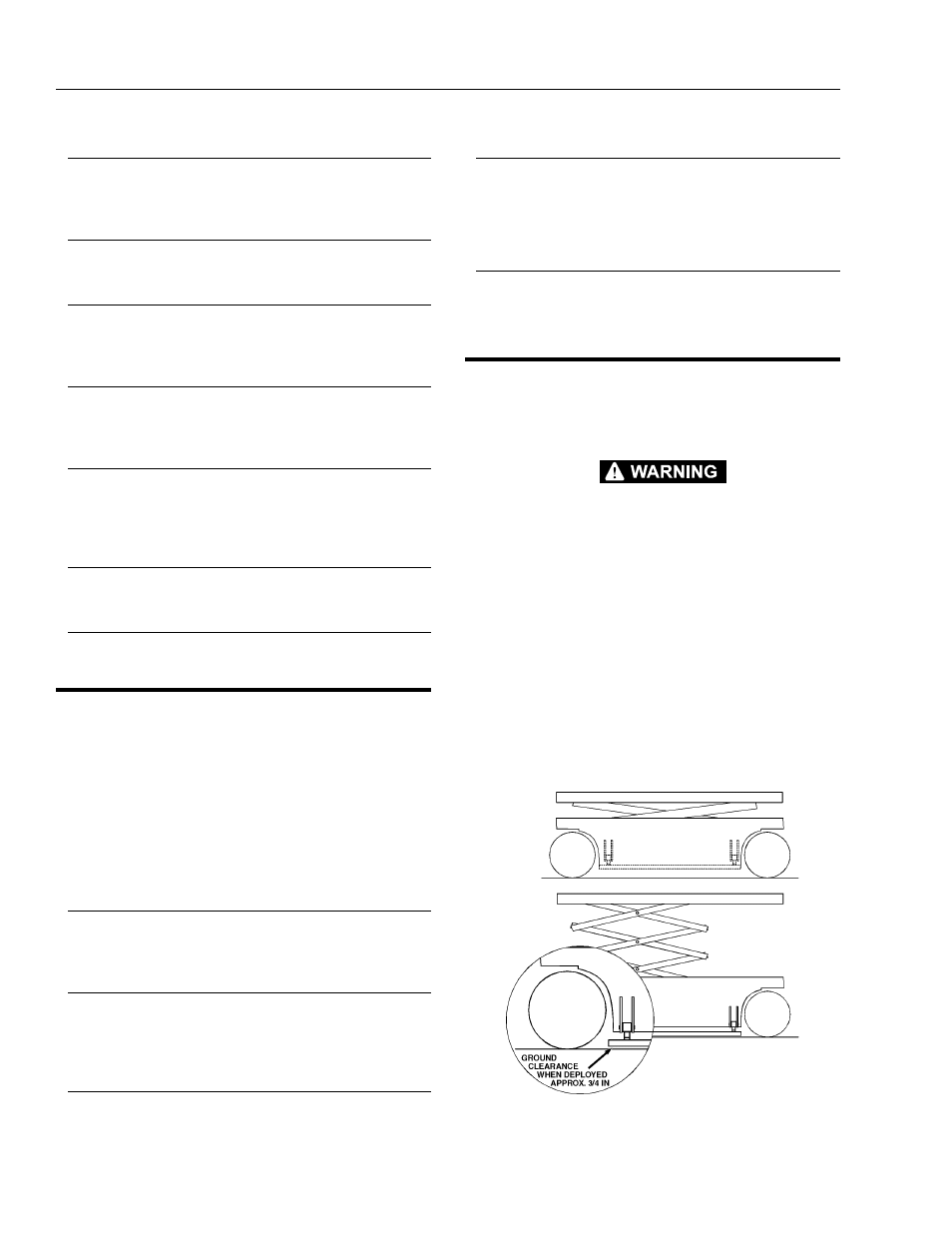

2. Raise and lower platform several times. Check for

smooth elevation and lowering. Check for High

Drive cut-out as platform begins to raise. Check that

pothole protection system is deployed when plat-

form is raised and that actuating rollers are in con-

tact with the connecting bar.

Figure 2-1. Pothole Protection System Operation