JLG 15ELI Service Manual User Manual

Page 34

SECTION 2 - SERVICE PROCEDURES

2-18

– JLG Lift –

3120779

The inspection and maintenance code numbers are as fol-

lows:

1.

Check for proper and secure installation.

2.

Check for visible damage and legibility.

3.

Check for proper fluid level.

4.

Check for any structural damage; cracked or broken

welds; bent/warped surface; broken cable strands.

5.

Check for leakage.

6.

Check for presence of excessive dirt or foreign

material.

7.

Check for proper operation and freedom of move-

ment.

8.

Check for excessive wear or damage.

9.

Check for proper tightness and adjustment.

10.

Drain, clean and refill.

11.

Check for proper operation while pump/motor is

running.

12.

Check for proper lubrication.

13.

Check for evidence of scratches, nicks or rust and

for straightness of rod.

14.

Check for condition of element; replace as neces-

sary.

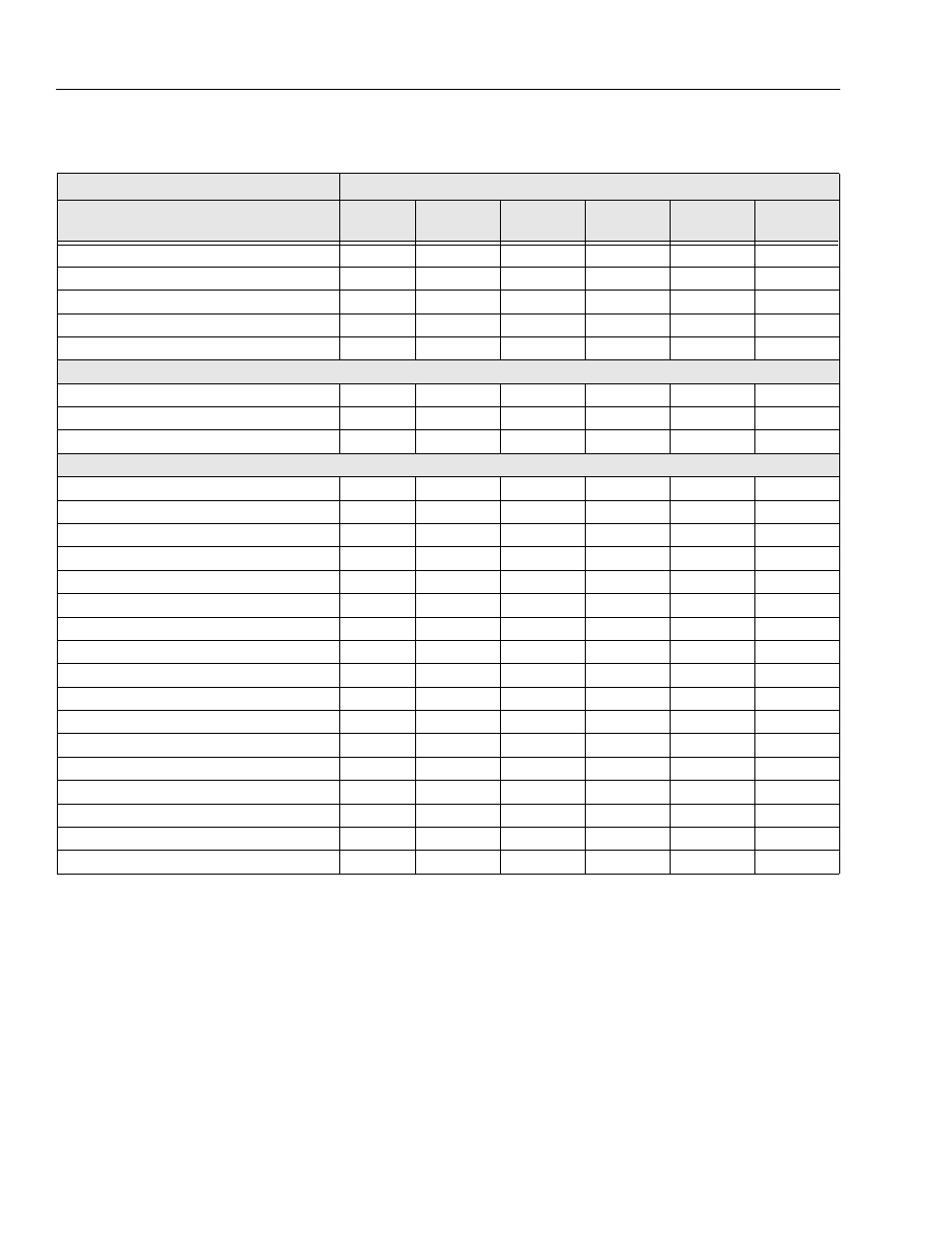

Table 2-3. Preventive Maintenance & Inspection Schedule.

AREA ON MACHINE

INTERVAL

PLATFORM

(10 HRS.)

DAILY

(50 HRS.)

WEEKLY

(200 HRS.)

MONTHLY

(500 HRS.)

3 MONTHS

(1000 HRS.)

6 MONTHS

(2000 HRS.)

1 YEAR

Control Switches

1,11

Placards and Decals

1,2

Control Tags

1,2

Electrical Cables

1,8

Handrail and Bar Gate

1,4

MAST

Mast Chains/Cables/and all component parts

1,4,7,9

Mast Sections

1,4,7

Mast Sequencing Cables

1,4,7,9

BASE FRAME

Batteries (DC Models)

1,3

5

12

Battery Charger (DC Models)

1

Power Cable (AC Models)

1,8

Electric Motor/Hydraulic Pump Unit

1

5

Hydraulic Hoses and Fittings

1

5

Hydraulic Oil Reservoir *

3

5

4

Hydraulic Oil Reservoir Breather

6,14

Manual Descent Valve

1,7

Lift Cylinder

1

5,6,13

4

Floor Brake Assembly

1,6,7,8

12

Placards and Decals

1,2

Wheels and Casters

1

8,9

12

Wheel Bearings

8

12

Power Switch (Ground Control Box)

1,11

Control Tags

1,2

Placards and Decals

1,2

Hoses and Cables

1,8