Parts replacement cycles and tolerances – MBW SP160 User Manual

Page 10

- 7 -

5.

Insert retaining ring (#15) and make certain it is fully

seated in groove.

6.

Coat the inner diameter of the dust wiper (#2) with

grease and insert into main body. The lip of the seal

should be facing out, and the shoulder should be

flush with the surface of the body.

7.

Attach trigger (#8) to valve spool with screw (#17). Do

not overtighten screw. place spring in the well of the

trigger (#8).

8.

Attach Handle (#3) to body with three screws (#17).

Use Medium strength loctite on these screws.

9.

Assemble lower cover (#5) to body with two screws

(#15)

10. Test action of trigger to ensure complete closing of

valve after trigger is released.

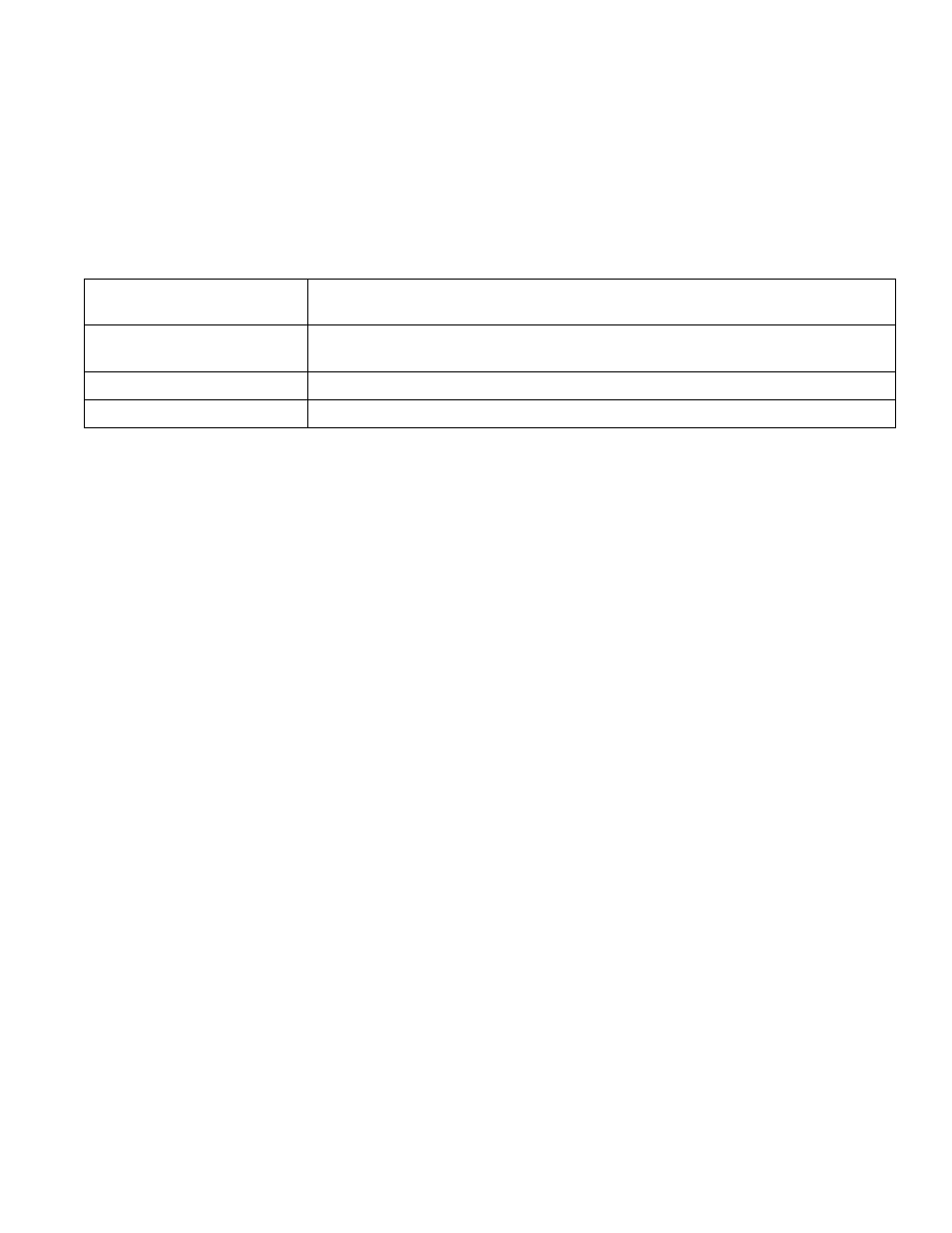

Parts Replacement Cycles and Tolerances

Bearings

Replace anytime a bearing is rough, binding, discolored or removed from housing or

shaft.

Hardware

Replace any worn or damaged hardware as needed. Replacement hardware should

be grade 5 and zinc plated unless otherwise specified.

Safety Decals

Replace if they become damaged or illegible.

Seals & Gaskets

Replace if a leak is detected and at every overhaul or teardown.