Venting – Bosch 125FX LP User Manual

Page 7

7

6 720 606 601

VENTING

WARNING: Do not reduce the vent pipe size and

do not common vent with any other vented appliance or

stove.

This appliance must be vented horizontally to the outside

with a sealed 4” single wall vent pipe. The appliance’s flue

gasses are under positive pressure and must travel through

a single wall 4” pipe that is sealed gas tight. The 4” single

wall vent pipe can be either stainless steel (AL29-4C) or

galvanized steel with at least 26 gauge. CEC recommends

the use of stainless steel vent pipe (which is equipped with

sealing gaskets) for ease of installation and durability. When

using galvanized vent pipe a minimum of 4 sheet metal

screws per connection must be installed and all seams must

be sealed with an approved high temperature silicone

sealant. The vent system must be gas tight. See Fig. 4 for

suggested venting installation diagrams.

The 125FX shall not be vented in combination with any

other appliance. This appliance may only be vented

horizontally with a dedicated sealed single wall vent. The

125FX shall not be vented into masonry chimneys or existing

vertical vents of any material.

CAUTION: 125FX vent system must be installed by a qualified

agency in accordance with these instructions. If improperly

installed a hazardous condition such as explosion or Carbon

Monoxide poisoning could result. Controlled Energy

Corporation will not be responsible for improperly installed

appliances.

Establish vent clearances that comply with vent

manufacturer’s specifications. In all cases follow local codes.

See table below.

The vent diameter must be 4”. The appliance should be

located as close to the point of termination as possible (see

Fig. 5 for locating the terminator). The vent system should

be as straight and short as possible. The vent pipe must be

4” single wall stainless steel (AL29-4C) or galvanized steel

pipe of 26 minimum gauge. Maximum vent length is 15

feet (4.6 m) with two 90-degree elbows. Subtract 5 feet

from the total vent length for each additional 90-degree

elbow used. No more than four 90-degree elbows may be

used. Any short vertical portion of vent pipe used in the

vent system shall be considered part of the allowable 15

feet (4.6 m) maximum run. Support the vent run at 4 foot

intervals with overhead hangers. Horizontal sections of vent

must rise ¼” for every foot of horizontal length. Any vent

section greater than 45 degrees is considered an elbow.

Note: Single wall pipe should not be used in concealed,

unoccupied or unheated locations. Listed thimbles or collars

are necessary to pass through wall partitions. If the vent

system passes through combustible areas where the vent

clearance requirements cannot be maintained, it is

permissible to chase straight sections of sealed 4 inch single

wall vent through 5 inch (or greater) Type-B vent. The

distance to combustibles using this chase technique is 1

inch. Note: Type-B vent should never be used as the actual

vent system for the 125FX, as it is not gas tight.

Freeze Warning:

As mentioned on Page 5, negative air pressure in cold

climates will cause a reverse airflow in the vent system that

can freeze and damage the Aquastar heat exchanger when

not in use. To prevent this the FXHOOD horizontal vent

terminator, which was supplied separately with the water

heater, needs to be installed on the end of the horizontal

vent run (see page 8). The FXHOOD is a CSA approved

vent terminator for the Aquastar 125FX and has a built in

back draft flapper.

Flue Gas Sensor:

The 125FX is equipped with a Flue Gas Sensor; it’s mounted

on the left side of the draft diverter (Flue Gas Sensor - #33

on page 22). Before leaving the installation site verify proper

Flue Gas Sensor operation by temporarily blocking

termination outlet. Once blocked then operate the heater,

the unit should shut down within 1-3 minutes when the flue

gases are blocked. You must reset the electrical power to

the heater after this safety test has been conducted,

otherwise the unit will not operate.

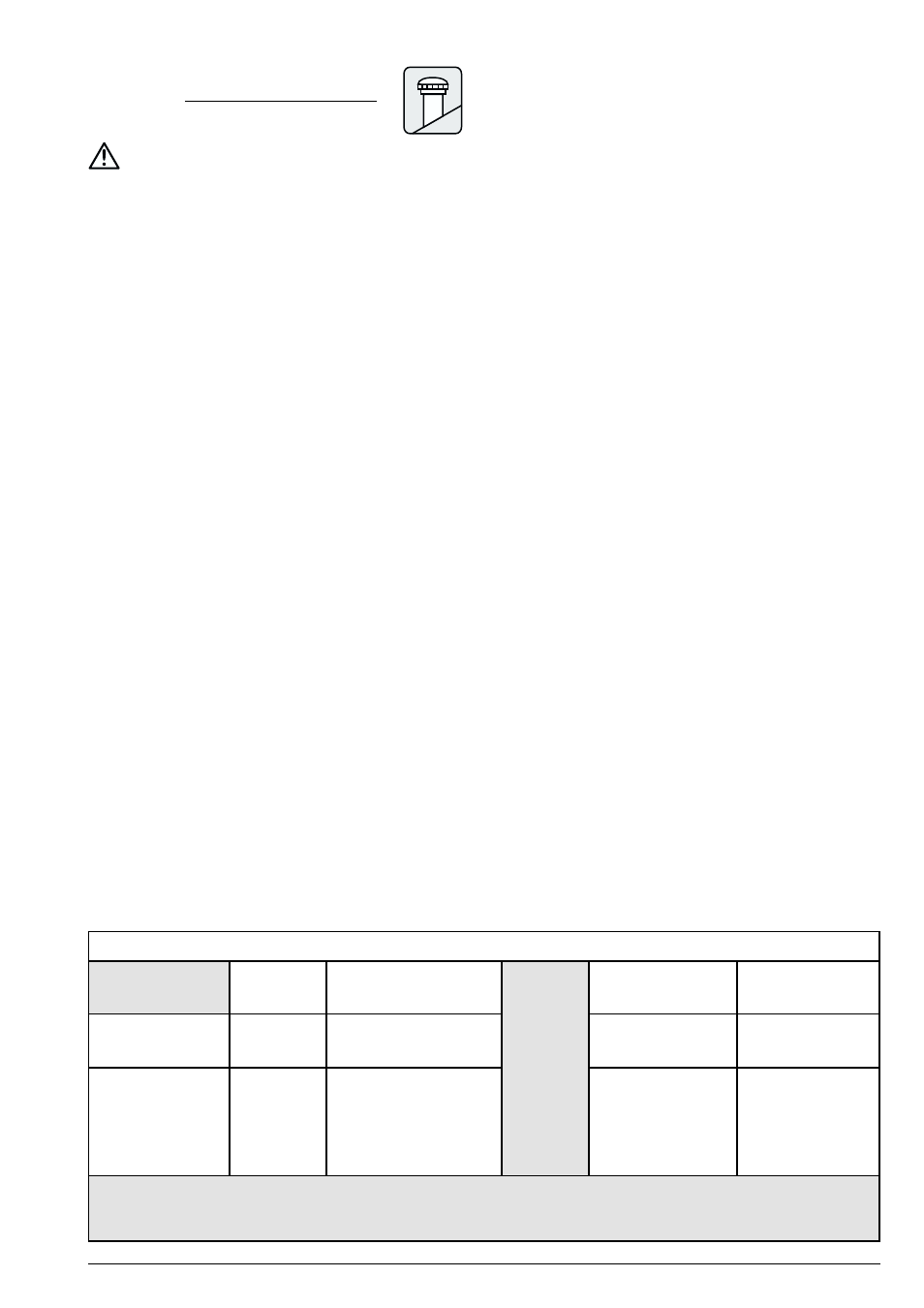

Venting Material

Options

Exhaust vent

diameter

Exhaust vent maximum

distance

Vent pipe within an

unenclosed space

Vent pipe within an

enclosed space

Single wall stainless

steel (AL29-4C)

sealed vent pipe

4 inch

15 feet (4.6 m) with two

elbows. Less 5 feet for

each additional elbow.

*See manufacturer's

specifications

*See manufacturer's

specifications

Single wall galvanized

vent pipe (min. 26

gauge and sealed

with high temperature

silicone)

4 inch

15 feet (4.6 m) with two

elbows. Less 5 feet for

each additional elbow.

3 inches

NOT PERMISSIBLE

Clearances

from venting

material

The flue gas exhaust temperature on the 125 FX is 356°F (180°C)

*Stainless steel (AL29-4C) vent pipe manufacturer's are Z-Flex, Protech and Heat Fab. The manufacturer's specified clearances

are identified on the venting material. NOTE: clearance distances are variable depending if the vent pipe is installed in an

enclosed or unenclosed space, the exhaust flue gas temperature and the orientation of the vent pipe.