Rubicon Express RE7003 User Manual

Page 2

RI7003G Page 2 of 3

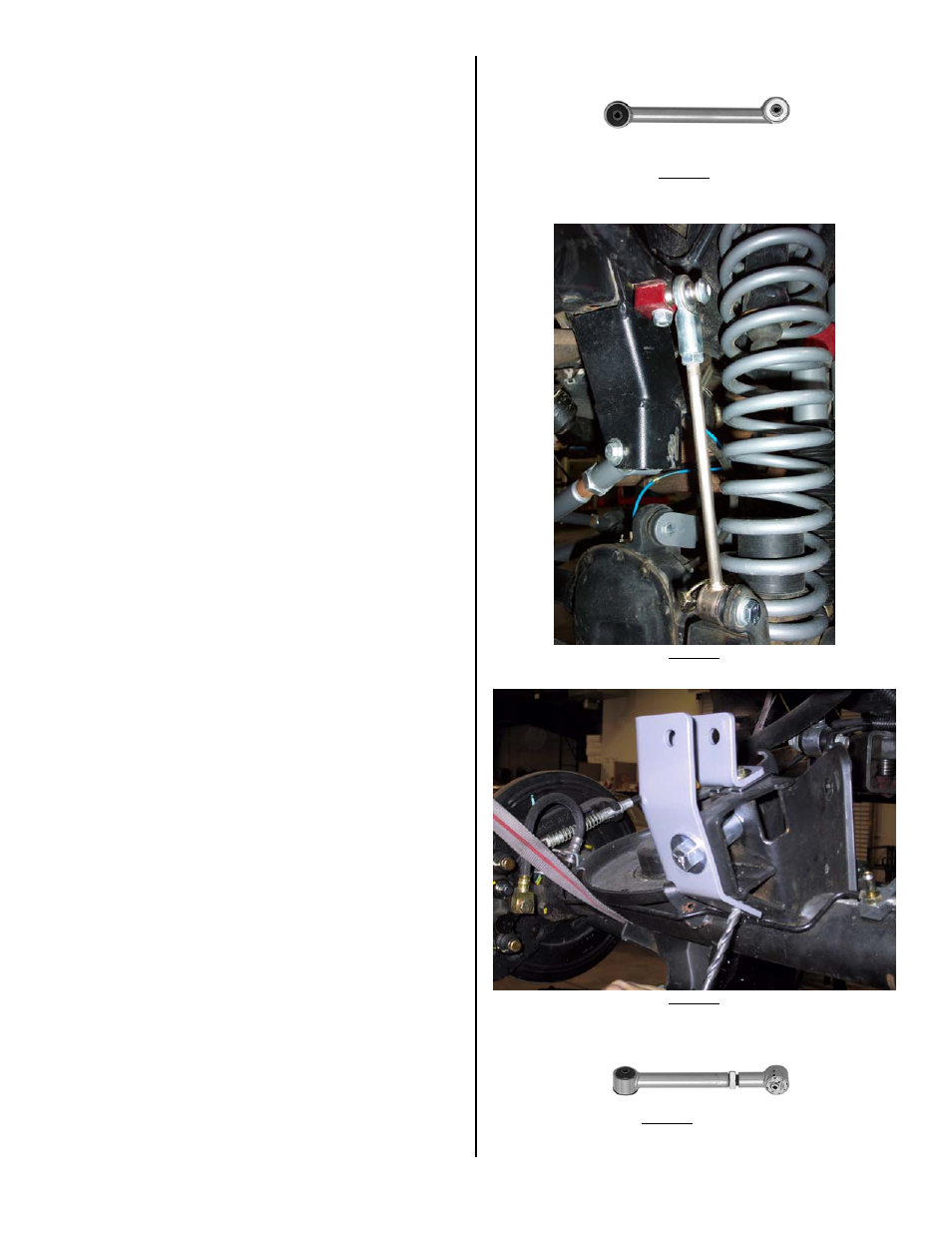

18. Install sway bar quick disconnects per instructions supplied with

disconnects (see Photo 2 for typical installation).

19. Re-drill front track bar axle bracket over toward drivers side ¾”,

center-to- center (or install optional adjustable front track bar).

Reconnect track bar at new hole.

-REAR AXLE-

20. Remove the rear shocks.

21. Remove the rear sway bar end links.

22. Support the rear axle.

23. Disconnect rear track bar at axle.

24. Remove the factory lower control arms.

25. Remove the rear springs.

26. Remove the plastic dust shield that covers the bolt securing the rear

track bar to the mount on the axle housing and discard.

27. Remove the Torx head bolt (t55) and disconnect axle end of track

bar. If not done previously

28. Install track bar bracket using the supplied ½” bolt and spacer (the

spacer goes in the location vacated by the track bar to prevent the

bracket from deforming when the bolt is tightened - see Photo 3 for

similar installation).

29. With the track bar bracket in place, drill two 5/16” holes in the axle

mount where the plastic dust shield was previously located, one on

top and one on angled surface.

30. Install the 5/16” hardware in the holes drilled in step #29. If

required, use supplied horseshoe shim to take up space between

bracket and axle mount at top 5/16” bolt.

31. Install the track bar in the track bar bracket using the Torx bolt

removed in step #27. It may be easier to do this later with weight

on the vehicle.

32. Install the lower control arms with the rubber bushing at the uni-

body and super flex end at the axle. The offset tube should be

mounted as low as possible (zerk on top - see Photo 1). Use the

factory hardware at the uni-body and supplied bolt at the axle

mount (don’t fully tighten until vehicle is back on the ground).

33. If installing optional upper control arms, set length 3/4” longer than

stock for a CV drive shaft (1/4” if trying to use std shaft) as a good

starting point (see general vibration in troubleshooting). Install the

upper control arms using the factory hardware (don’t fully tighten

until vehicle is back on the ground). Super flex end should be at

axle with zerk on top (see Photo 4).

34. If installing optional cam bolts, install per instructions included with

cam bolts (see General Vibration in Troubleshooting).

35. Remove the rubber insert from the rear bump stop. Remove the

bump stop cup. Place the 1-1/2" bump stop extension between the

bump stop cup and the frame using the supplied longer metric

hardware.

36. Install springs. Spring compressors may be helpful.

37. Install replacement sway bar end links.

38. Install longer rear shocks.

39. If using, install transfer case drop kit by supporting one side of

transfer case with floor jack. Remove hardware from one side of

crossmember. Install spacers and new hardware. Tighten to 55

ft./lbs. Repeat on opposite side. NOTE: If used on a vehicle

with a 6 speed manual transmission contact between the

shifter and body may occur in 2

nd

, 4

th

, and Reverse. In this

case it will be necessary to remove the shift boot to verify

for clearance and possibly modify the body to allow a

minimum of 1/8” clearance between the shifter and the

body.

40. Install all tires.

41. Thoroughly bleed brake lines and check for leaks.

42. Double-check all nuts and bolts to factory torque specs.

43. Test drive and note location of steering wheel. Adjust drag link to

center steering wheel.

44. Align vehicle as soon as practical. A good rule of thumb is minimum

factory caster and maximum factory toe-in.

45.

Recheck all bolts after 50 miles and again after every off-road

excursion.

< FRAME END (RUBBER) - PHOTO 1 - AXLE END (ZERK ON TOP) >

PHOTO 2

PHOTO 3

< UNI-BODY END) – PHOTO 4 - AXLE END (ZERK ON TOP) >