Rubicon Express RE6300 User Manual

Page 3

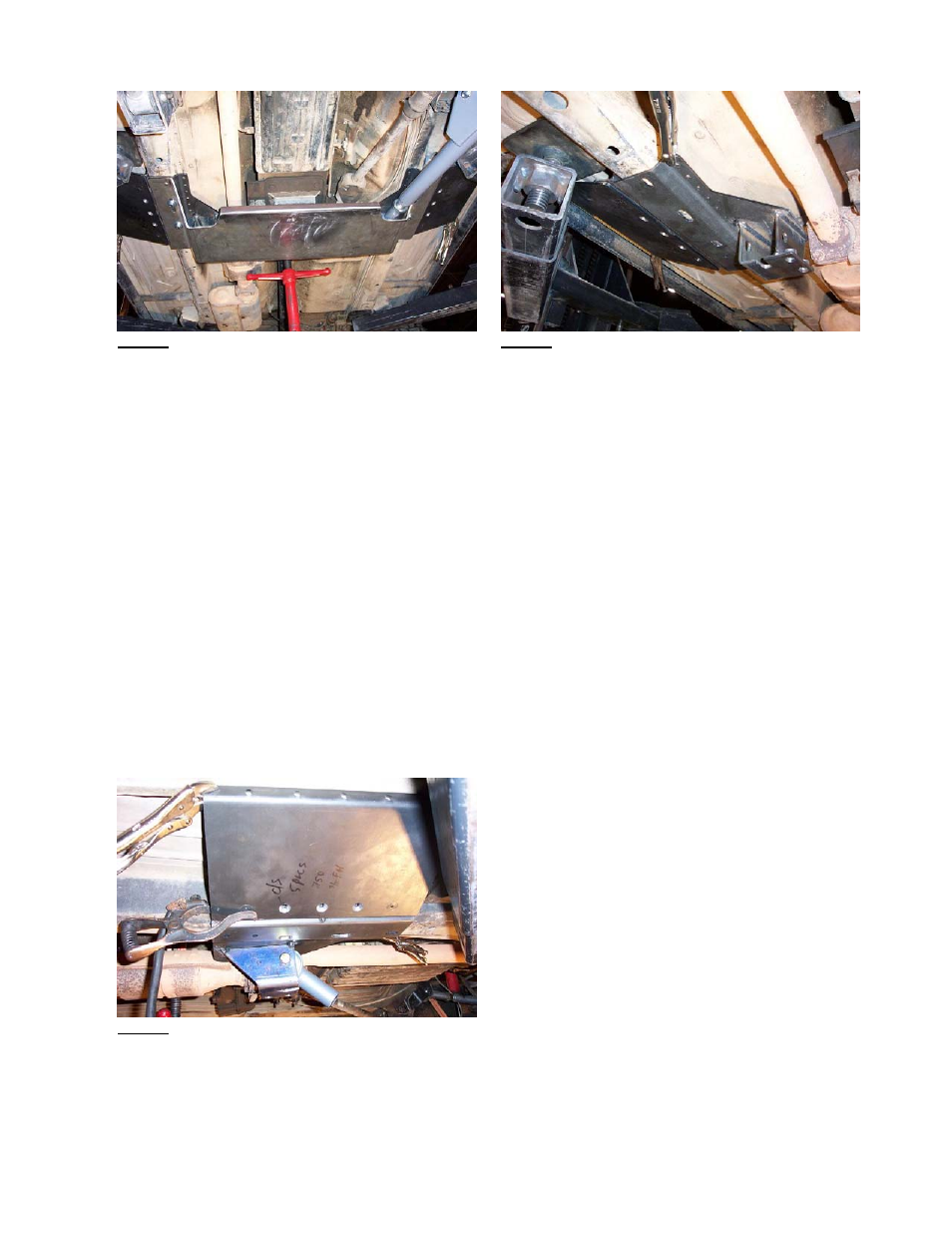

Photo 3

Photo 4

D. Place multi-hole bolting strips on top of the pinch welds and clamp tightly into position so the holes align with the

holes in the control arm mounts plates. Carefully lower the crossmember by removing the 10mm and ½” flat head

bolts. Be sure control arm mounts have not moved and drill 5/16” holes through pinch weld at front and rear

holes of the of the control arm mounts – refer to Photo 4. Loosely secure up through the bolting strips with

supplied 5/16” hex head bolts. Repeat drilling and bolting for remaining pinch weld holes.

E. Drill a 1-1/8” hole in the bottom of each uni-frame about 1-1/2” behind the control arm mounts. These will be used

to feed the short PEM nut strips up into the uni-frame to secure the rear of the control arm mounts. Drill 3/8” holes

through the bottom of the uni-frame at the two rear (counter-sunk) holes in the control arm mounts. Slide the

PEM-nut strip up into the 1-1/8” hole (with nuts on top) and position so nuts align with the two control arm holes

(NOTE: It will be very helpful to tape a stiff wire to the PEM-nut strips before feeding them into the uni-frame so

you can align them without loosing them). Install and loosely tighten four supplied 3/8”- 16 flat head bolts through

the control arm mounts/uni-frame and into the PEM nuts. Now, fully tighten the 5/16” bolts in the control arm

mounts, and then tighten the four 3/8” flat heads.

F. Loosely bolt side braces to control arm mounts with supplied 3/8” flat head bolts and tightly clamp the side braces

to the outside of the vertical body pinch weld - refer to Photo 5. Drill 5/16” holes through the pinch weld at the

five holes in the side braces. Place the 5-hole PEM-nut strips on the inside of the pinch welds and bolt through

brace/pinch weld with supplied hex bolts. Now, tighten the 3/8” flats heads holding braces to control arm mounts.

Photo 5

G. Carefully skip weld the very front and rear edges of the control arm mounts along the bottom and side of the uni-

frame. CAUTION - a certified welder that can weld thick metal to thin should do this and care should be taken to

protect wiring, fuel lines, brake lines, etc, and to not ignite coatings etc. on fire. Paint welded areas for protection.

RI6300 Page 3 of 4