Maintenance (cont.) fan blades, Pump servicing (cont.) – L.B. White 125-210K Tradesman User Manual

Page 14

MAINTENANCE (cont.)

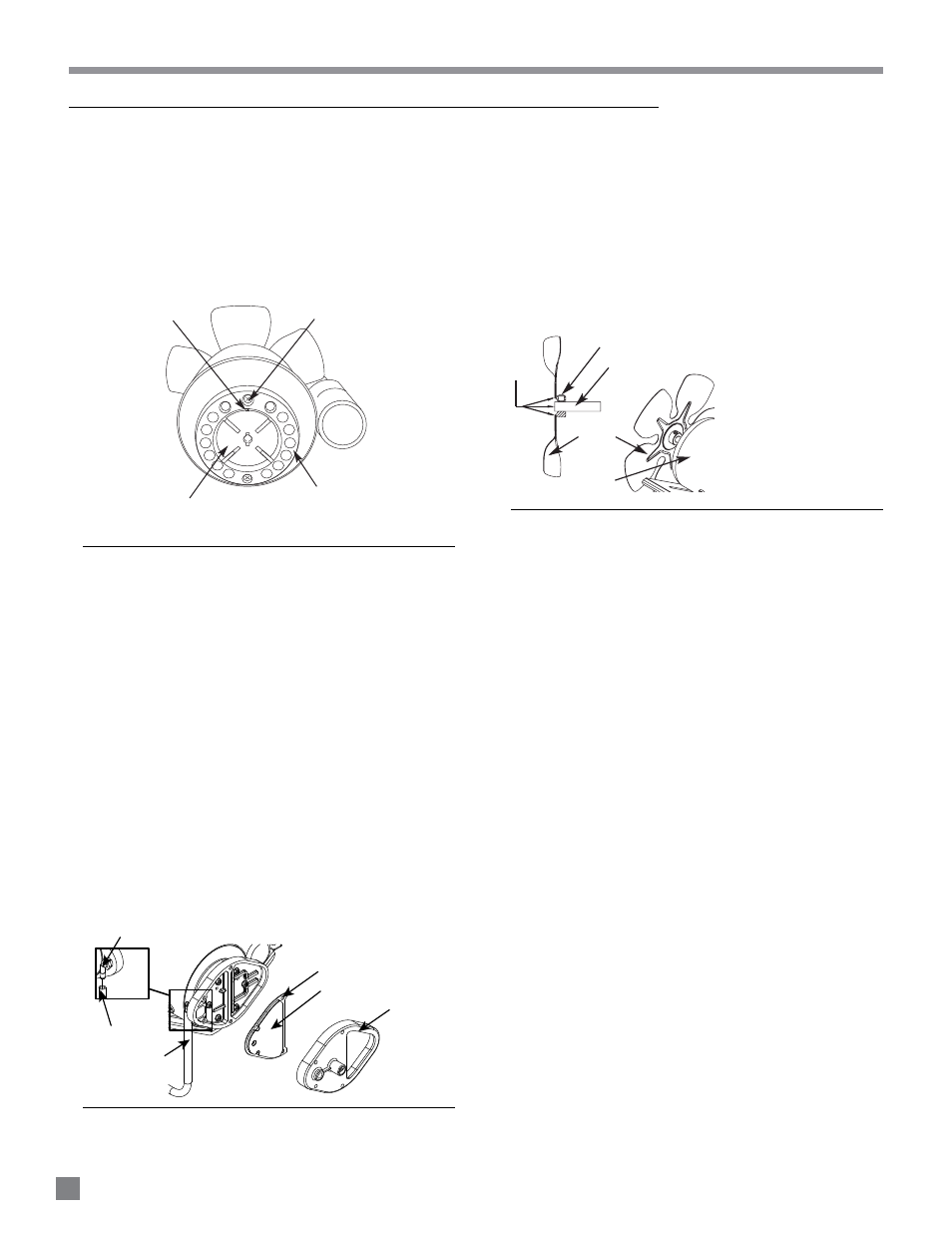

FAN BLADES

CLEAN EVERY SEASON OR AS NEEDED

- Remove upper shell (See Air Intake Filter Figure 10).

- Use M6 Allen wrench to loosen set screw which holds fan

blade to motor shaft.

- Slip fan blade off motor shaft.

- Clean fan blade using soft cloth moistened with kerosene

or solvent.

- Dry fan blade thoroughly.

- Reinstall fan blade to motor shaft.

- Place fan blade hub flush with end of motor shaft.

- Place set screw on flat of shaft.

- Tighten screw firmly (40-50 inch-pounds/4.5-5.6 N-m).

Reinstall upper shell.

Figure 15 - Fan Assembly

Motor

Flush

Fan Blade

Motor Shaft

Set Screw

- Slightly loosen the pump body screws using a medium

screw driver.

- Position pump body to set rotor gap to .003’’~.004’’ at top

dead center and retighten pump body screws.

- Verify the gap using calipers,

a micrometer or a dollar bill.

- Reinstall the end pump cover.

- Reinstall air output filter and lint filter.

- Reinstall end filter cover and air pressure gauge.

- Reinstall fan guard and upper shell.

Figure 13 - Rotor Gapping

Figure 14 - Check Air leaks around Pump.

Pump Body Screw

Pump Body

Rotor

Rotor Gap

13

IMPORTANT:

The newly inserted rotor must be gapped

properly before you reinstall the end pump cover.

PUMP SERVICING (cont.)

●ROTOR GAPPING

●AIR LINE (LEAKING)

REPLACE IF

SPLIT,

CRACKED OR AS NEEDED.

- Remove air line from air line fitting (See Figure 14) and from

nozzle adaptor.(See Nozzle, page 14)

- Reinstall Air line to air line fitting and nozzle adaptor.

●END FILTER COVER & GASKET(LEAKING)

REPLACE IF

SPLIT

,CRACKED OR AS NEEDED.

- Replace End filter cover.(See Air output filter,page 12)

- Replace Air ouput filter.(See Air output filter,page 12)

Air Line Fitting

Air Line

Air Line

Air Outfilter Filter

Gasket

End Filter Cover