Operations – Steele Products SP-PB130 User Manual

Page 9

Once assembly is complete, the machine is

ready for a test run. The purpose of a test run is

to identify any unusual noises and vibrations, as

well as to confirm that the machine is perform-

ing as intended.

To test run the Model SP-PB130,do these steps:

1. Make sure that all tools have been removed

from the scroll saw.

2. Turn the variable speed/power knob clock-

wise to turn the scroll saw ON.

3. Once the scroll saw is running, listen for any

unusual noises. The machine should run

smoothly with little or no vibrations.

• If there are any unusual noises or vibra-

tions, stop the scroll saw immediately by

pushing the paddle switch down.

4. Unplug the scroll saw and investigate the

source of the noise or vibration. DO NOT

make any adjustments to the scroll saw

while it is plugged in. The scroll saw should

not be run any further until the problems

are corrected.

THIS MACHINE produces

sawdust that may cause

allergic reactions or res-

piratory problems. Wear

a respirator in addition

to using a dust collector.

THIS MACHINE throws

wood chips and sawdust.

Wear safety glasses or a

face shield during all

operations.

KEEP loose clothing

rolled up and out of the

way of machinery and

keep hair pulled back.

Test Run

OPERATIONS

17

Important issues regarding blade perfor-

mance:

•

Scroll saw blades wear out and must be

replaced frequently. Typically a blade will

stay sharp anywhere from to 2 hours

1᷐2

depending on how the blade is used and

what type of material is being cut.

•

Best cutting results will be achieved when

cutting material less than 1" thick.

•

When cutting material thicker than 1", use a

very slow feed rate.

•

Blades will become dull quickly whenever

making cuts in plywood, hardwoods, and

laminates.

•

Exerting excessive side pressure on the

blade greatly increases the chance of blade

breakage.

Teeth Per Inch Width Thickness Strokes-Per-Minute Material Being Cut

10

0.110"

0.020"

1200-1700

General purpose blade for cutting hard

and soft woods between 3

᷐16" and 2".

Also good for plastics, paper, felt, and

bone.

15

0.110"

0.020"

600-1200

Good for cutting very thin wood and

plastic between 3

᷐32" and 1᷐2".

18

0.095"

0.010"

500-600

Good for tight radius cutting in thin

hard and soft woods between 3

᷐32" and

1᷐8".Also good for veneer, bone, ivory,

and plastics

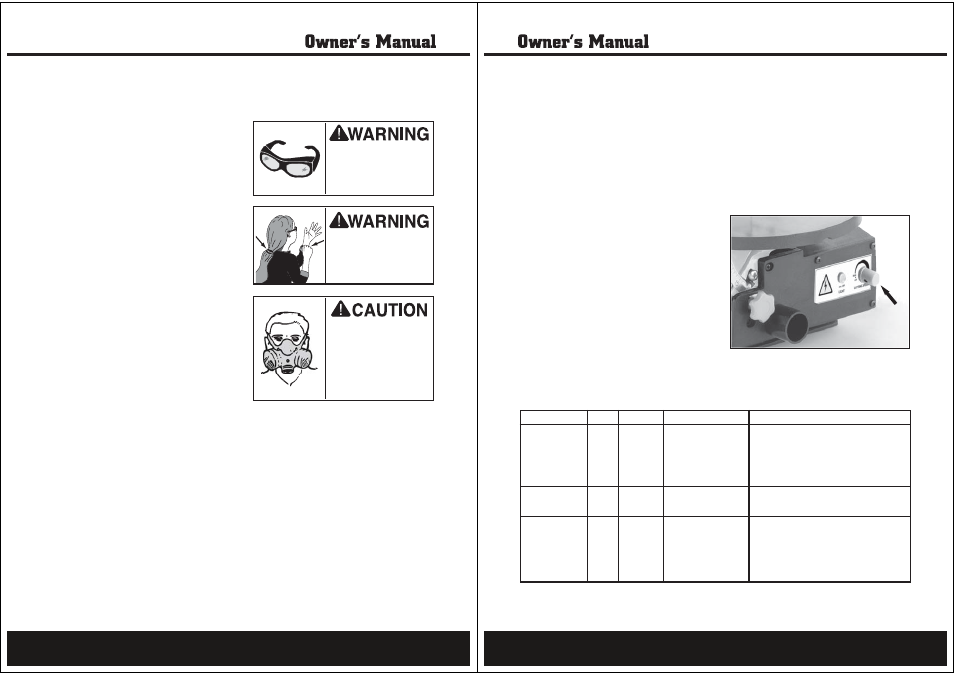

To change the blade speed:

The blade speed is variable between 550 and

1700 strokes-per-minute (SPM). Blade speed

adjustments are made using the variable speed

/power knob(Figure 11)on the front of the

scroll saw.

Figure 11. Variable speed/power knob.

Blade Selection Table

Blade Speed

Blade Information

OPERATIONS

18