Quality construction features – Bryan Boilers CLM Series User Manual

Page 3

Low initial cost, high operating efficiency

deliver substantial return on investment

and inspection, front and rear openings, upper and lower

drums.

L. Steam boilers with extra large drum with high steam

release area ensure stable water level and dry steam.

M. Steel plate boiler base with lightweight, high tempera-

ture insulating firebrick combustion chamber, designed

for maximum combustion efficiency.

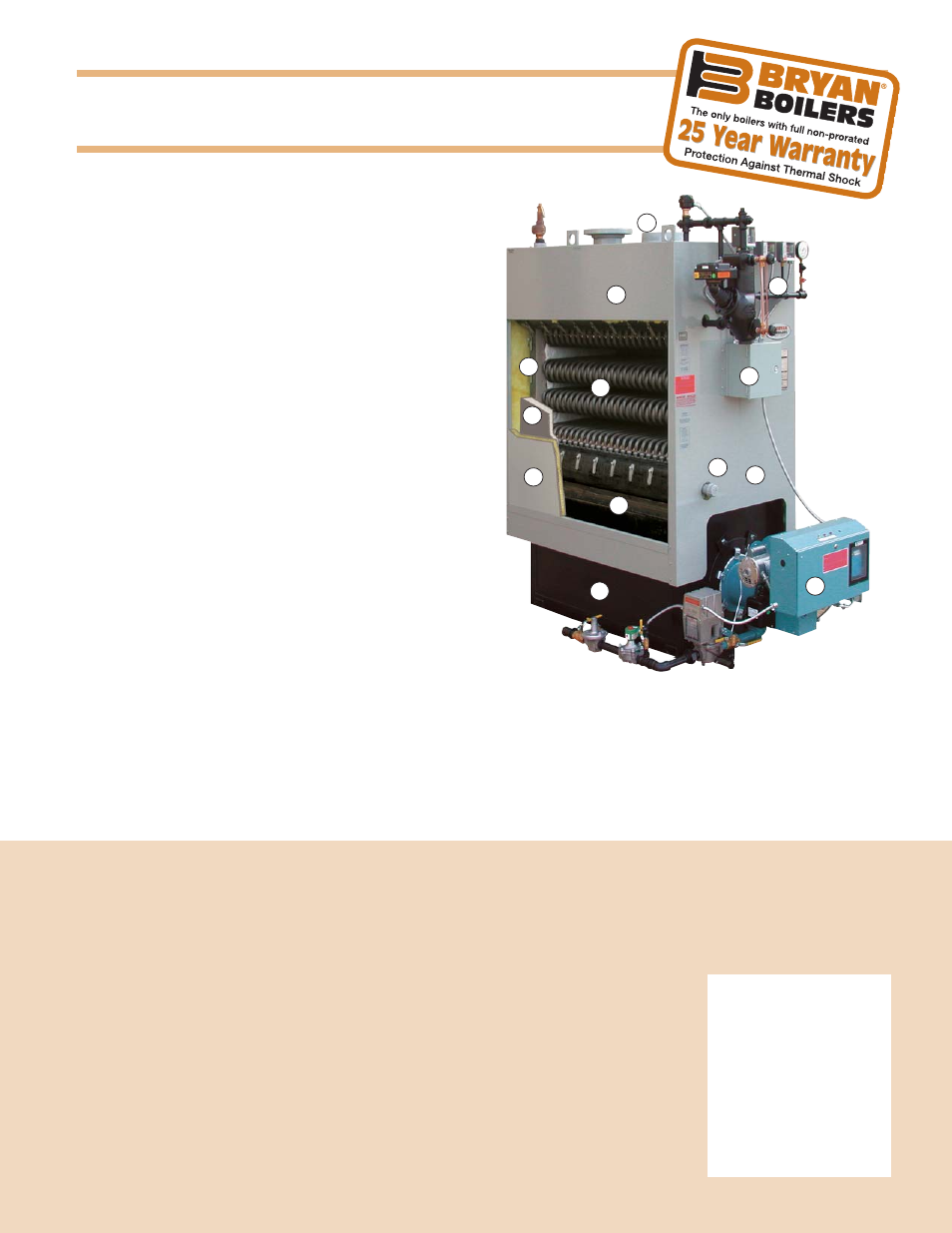

Quality Construction Features

A. Heavy steel boiler frame, built and stamped in accor-

dance with the appropriate ASME Boiler Code.

B. Large volume water leg downcomers promote rapid

internal circulation, temperature equalization and efficient

heat transfer.

C. Bryan bent water tubes are flexible, individually re-

placeable without welding or rolling. Never more than two

tube configurations.

D. Boiler tube and furnace area access panel: heavy

gauge steel casing with 2" high temperature ceramic fiber

and insulation, bolted and tightly sealed to boiler frame.

E. Jacket access panels make the interior of the boiler

easily accessible for service and inspection.

F. Heavy gauge steel boiler jacket with rust-resistant zinc

coating and attractive enamel finish, insulated with 1½"

fiberglass to insure exceptionally cool outer surface.

G. Minimum sized flue vent.

H. Forced draft, flame retention head type burner. Effi-

cient combustion of oil or gas, quiet operation.

I. All controls, gauges, relief valve(s) are factory installed

and wired and easily accessible for servicing.

J. Electrical box: all controls installed and connected to

terminal strip.

K. Water side or steam side interior accessible for cleanout

•

True “flexible water tube”

design guaranteed shock free

•

Longer service life with

superior performance

•

Full five sq ft of heating

surface per BHP

Water Boiler

Combination thermometer and pres-

sure gauge, ASME-rated boiler relief

valve, water temperature control (240°F

max std.), high limit control, probe

LWCO.

Steam Boiler

Steam pressure gauge, steam pres-

sure control, combination low water

cutoff and pump control, auxiliary low

water cutoff, high limit pressure con-

trol, ASME-rated boiler relief valve,

water glass set.

Straight gas fired unit

Electronic combustion safety control,

automatic operating gas valve, safety

gas valve, pilot solenoid valve, pilot

ignition assembly, main manual gas

shut-off valve, pilot cock, pilot and

main gas pressure regulators, air safety

OPTIONAL EQUIPMENT:

1. Manual reset high limit control

2. Manual reset low water cutoff

3. Auxiliary low water cutoff

4. Combination low water cutoff

and feeder

5. Alarm bells or horns

6. UL, CUL, CSD-1, FM, IRI or

other insur-ance approved

control systems

7. Control panel mounted on boiler

8. Indicating lights, as desired

9. Lead-lag systems for two or

more boilers with or without

outdoor reset control

10. Draft control system

11. Special construction: left hand,

Knocked Down.

OPTIONAL CONSTRUCTION:

When ordering, please specify:

1. Boiler size

2. Supply and return tempera-

tures required

3. Boiler relief valve setting

4. Type of fuel: natural, LP, or

other gas and/or No. 2 oil

5. If gas, type, BTU content,

specific gravity and pressure

available

6. Electric power voltage, phase

and frequency

7. Optional extra equipment or

construction

8. Special approvals required

(UL, CUL, CSD-1, FM, or IRI)

9. Altitude

Steam boiler

Optional construction to ASME Power

Boiler Code requirements for pressure

exceeding 150 psi to maximum of 300

psi design pressure.

Hot water boiler

Optional construction to ASME Power

Boiler Code requirements for tempera-

tures exceeding 240° F and/or pressure

exceeding 160 psi to maximum of 285°

F operating and 300° F design tempera-

ture and 250 psi.

Bryan CLM Series Boilers Standard and Optional Equipment

STANDARD EQUIPMENT FURNISHED

switch, control panel, all controls in-

stalled and wired.

Straight oil fired unit

Electronic combustion safety control,

dual oil valves, oil ignition transformer,

two-stage fuel unit, direct spark

ignition of oil, oil nozzle assembly,

control panel, all controls installed

and wired.

Combination gas-oil unit

Electronic combustion safety control,

automatic operating gas valve, safety

gas valve, pilot solenoid valve, pilot

ignition assembly, main manual gas

shut-off valve, pilot cock, pilot and

main gas pressure regulators, air

safety switch, manual fuel selector

switch, dual oil valves, gas pilot for

both fuels, two-stage fuel unit, nozzle

assembly, control panel, all controls

installed and wired.

A

G

B

C

K

J

D

I

E

H

L

F

M