Liebherr robot system for bin picking, Process description, Requirement – Liebherr Bin Picking User Manual

Page 2: Visual data acquisition and analysis

Flexible Robot Systems

2

Process Description

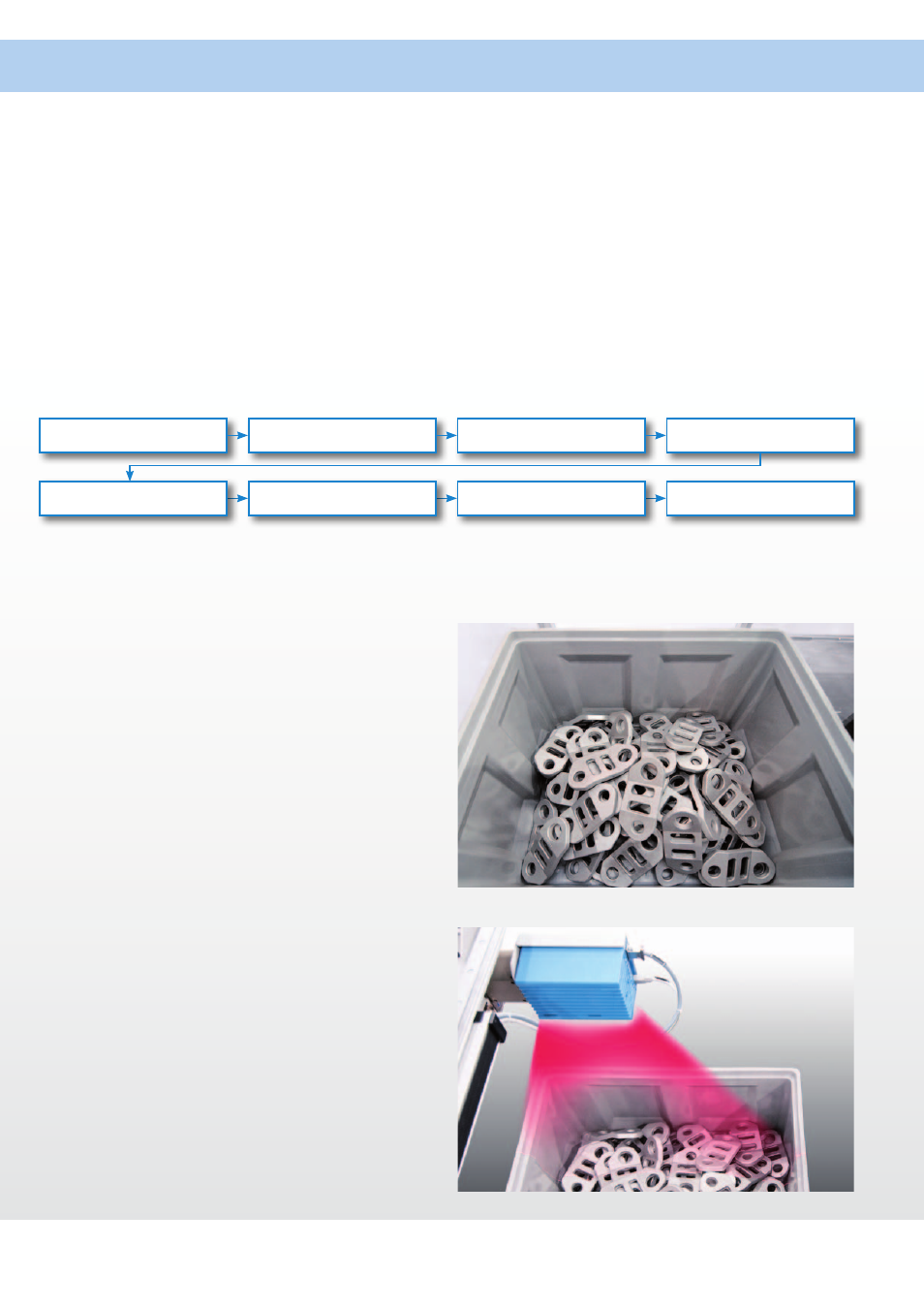

Unloading the work piece out of dunnage is a complex interaction between a vision system, software and robot. According

to the part spectrum all process-relevant steps need to be synchronized to reach an optimum grip and positioning result.

Requirement

Randomly arranged parts should be

removed from a transport container.

Visual Data Acquisition

and Analysis

A reliable and dynamic 3D object recognition

system visually acquires and analyzes the data.

Bin picking is one of the most challenging industry auto-

mation applications. The foundation of this system is the

automatic unload of randomly arranged work pieces out of

dunnage. To date there are very few robot designs that meet

both the sturdiness and cycle time requirements. Liebherr

offers flexible robot systems with which bin picking can be

Visual Data Acquisition

Robot Path Planning

Data Analysis

Collision Detection

Object Identification

Object Removal

Object Selection

Object Positioning

Liebherr Robot System for Bin Picking

economically automated. Liebherr has designed and created

robot systems that help automate manufacturing processes

to increase capacity thereby lowering costs. Many tasks can

be solved with the long established tried and tested work

piece handling components from the Liebherr automation

systems area.