Technical data, Optional equipment, Propping arrangements – Liebherr LHM 180 User Manual

Page 7: Quay load arrangements, Capacity and classification, Main dimensions, Working speeds, Hoisting heights, Weight

LHM 180

7

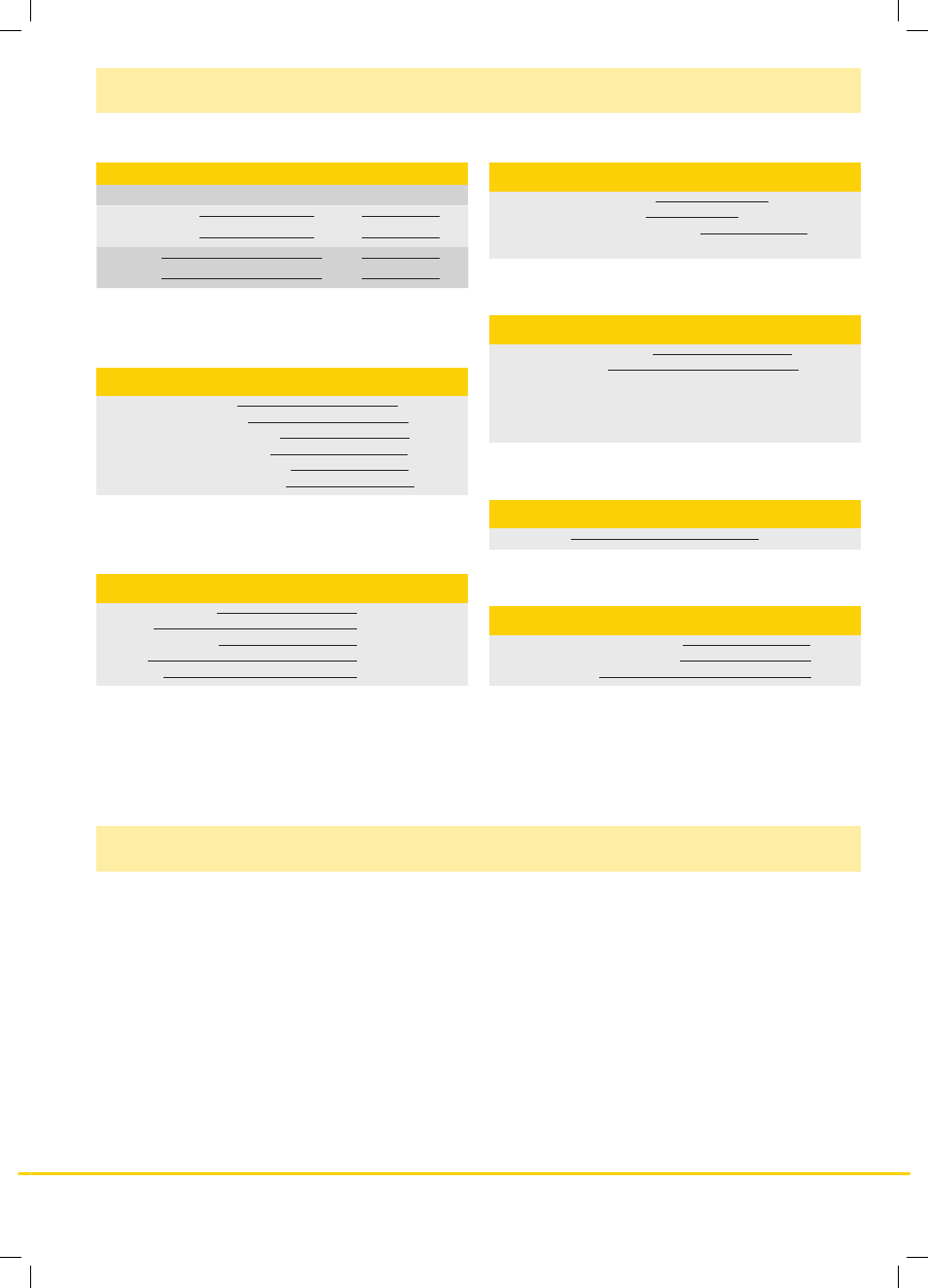

Propping arrangements

Standard supporting base

10 m x 10 m

Standard pad dimension

4 x 5.5 m x 0.8 m

Standard supporting area of pads

4.4 m

2

Optional size of supporting pads and bases on request

Quay load arrangements

Uniformly distributed load

1.36 t/m

2

Max. load per tyre

5.2 t

Due to a unique undercarriage design its parameters (pad

sizes, supporting base and number of axle sets) can easily

be adapted to comply with the most stringent quay load

restrictions.

Technical data

Capacity and Classification

Capacity Classification

Grab operation

< 24 t

A8

Grab operation

< 35 t

A7

Standard

64 t

A4

Heavy lift

76 t

A3

Main dimensions

Min. to max. outreach

9—35 m

Height of boom fulcrum

12.5 m

Tower cabin height (eye level)

17.6 m

Overall height (top of tower)

23.5 m

Overall length of undercarriage

12.6 m

Overall width of undercarriage

5.4 m

Working speeds

Hoisting / lowering

0 — 75 m/min

Slewing

0 — 1.6 rpm

Slewing (Heavy lift)

0 — 0.18 rpm

Luffing

0 — 83 m/min

Travelling

0 — 5.4 km/h

Hoisting heights

Above quay at minimum radius

42 m

Above quay at maximum radius

19 m

Below quay level

12 m

Weight

Total weight

approx. 165 t

1. Cycoptronic

®

- anti-sway system

2. Teach-In

®

- semi-automatic point to point system

3. Vertical Line Finder

®

- diagonal pull preventing system

4. Dynamic Anti-Collision System

5. Synchronizing Crane Control System

6. Economy software - for optimised fuel consumption

7. Modem for data transfer and telediagnosis

8. SCULI

®

(crane analyzer with various features)

9. Data Recorder

10. Machine Data Recording

11. Video monitoring system

12. Radio remote control

13. Autopropping undercarriage

14. Cyclone air-intake system for the engine

15. Low temperature package

16. Tropical temperature package

17. Customer-specific painting & logo

18. Additional (driven) axle sets

19. Axle sets equipped with foamed tyres

20. Different supporting bases and pad sizes

21. And many more as per customers requirements

Optional equipment