Bulk handling – Liebherr LHM 420 User Manual

Page 10

10

Bulk Handling

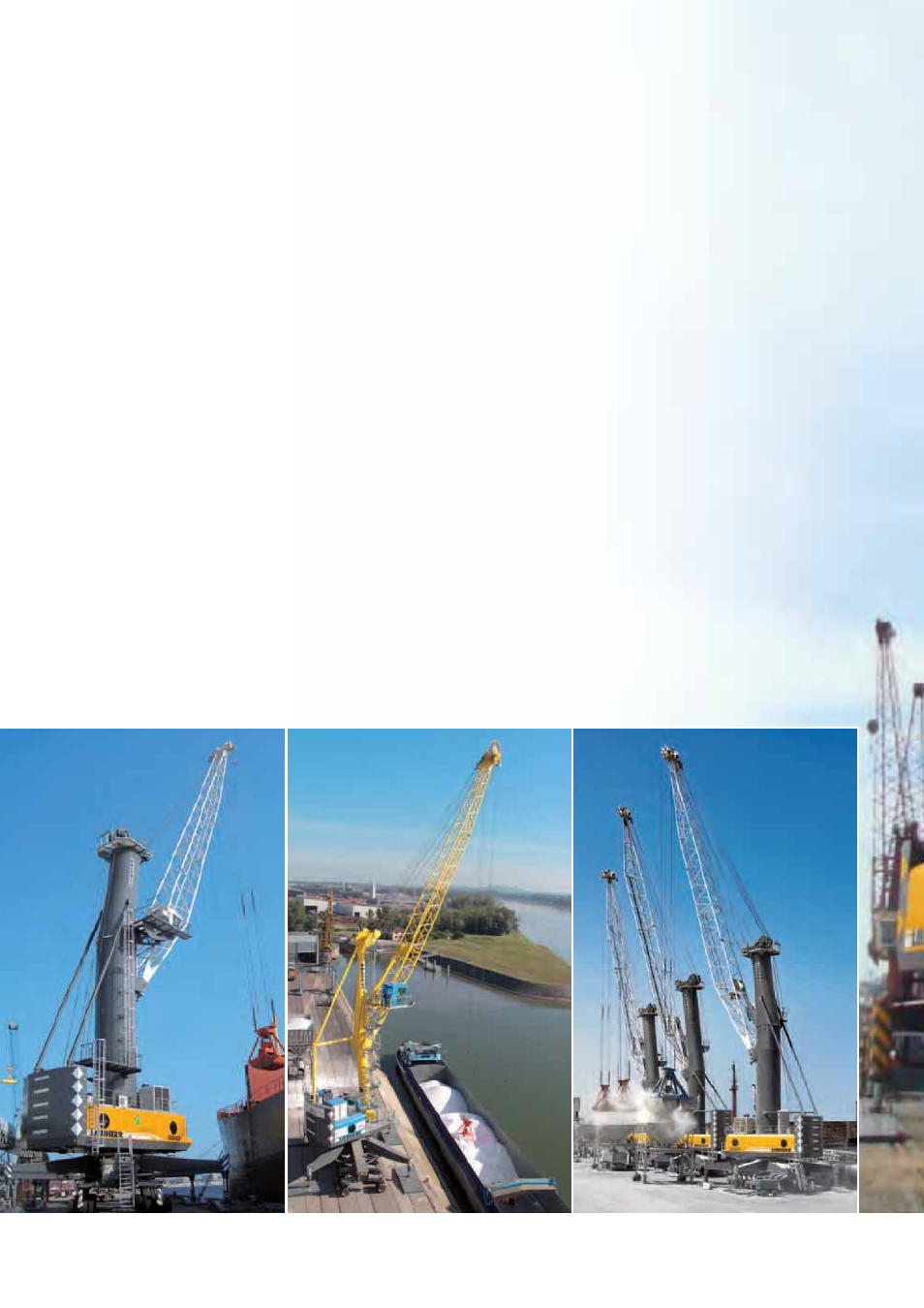

LHM 550 SSA Marine Gulf

LHM 280 CCI de Colmar et du Centre-Alsace

LHM 550 AGAM

s¬ $URING¬GRAB¬OPERATION¬HOISTING¬SLEWING¬AND¬LUFlNG¬ARE¬

driven simultaneously at maximized speed to achieve

the highest (possible) turnover

s¬ $URING¬GRAB¬lLLING¬FEATURES¬SUCH¬AS¬AUTOMATIC¬LOWERING¬

and hoisting guarantee the optimum filling level of the

grab

s¬ 4HE¬ SLACK¬ ROPE¬ MONITORING¬ SYSTEM¬ ENSURES¬ EXTENDED¬

lifetime of the ropes and increases operational safety

s¬ 2EVERSE¬POWER¬IS¬RETURNED¬TO¬THE¬DRIVE¬PROCESS¬THROUGH¬

closed loop hydraulics which results in reduced fuel

consumption

s¬ 4HE¬#YCOPTRONIC

®

anti-sway system automatically com-

pensates for all rotational swing, transverse and longi-

tudinal sway of the load at maximum speeds

s¬ 4O¬ PROVIDE¬ SAFE¬ AND¬ STRESS FREE¬ WORKING¬ CONDITIONS¬ FOR¬

the operator, Liebherr offers the Cycoptronic

®

inclucing

Teach-In

®

feature, a semi-automatic system, which pi-

lots the crane from the vessel hatch to the quay without

any sway. Especially for bulk operation into hoppers, the

Teach-In

®

system increases turnover and ensures con-

sistent turnover rates during the entire ship unloading

The optimised interaction between powerful hydrostatic transmission and advanced Liebherr electronics ensures short,

productive working cycles in bulk handling. Independent of whether using a motor grab or a four-rope grab, all important

handling parameters such as the volume to be lifted with each grab, the opening/closing and hoisting speeds, simultane-

ous functions, winch synchronisation etc. are optimized using specially developed Liebherr electronics.