Caution – Briggs & Stratton 40248 User Manual

Page 20

18

www.briggsandstratton.com

Engine parts should be kept clean to reduce the risk of

overheating and ignition of accumulated debris. Use the

same instructions given above for the engine.

Oil

Oil Recommendations

NOTE: When adding oil to the engine crankcase, use

only high quality detergent oil classified “For Service SF,

SG, SH, SJ” or higher. DO NOT use special additives.

1.

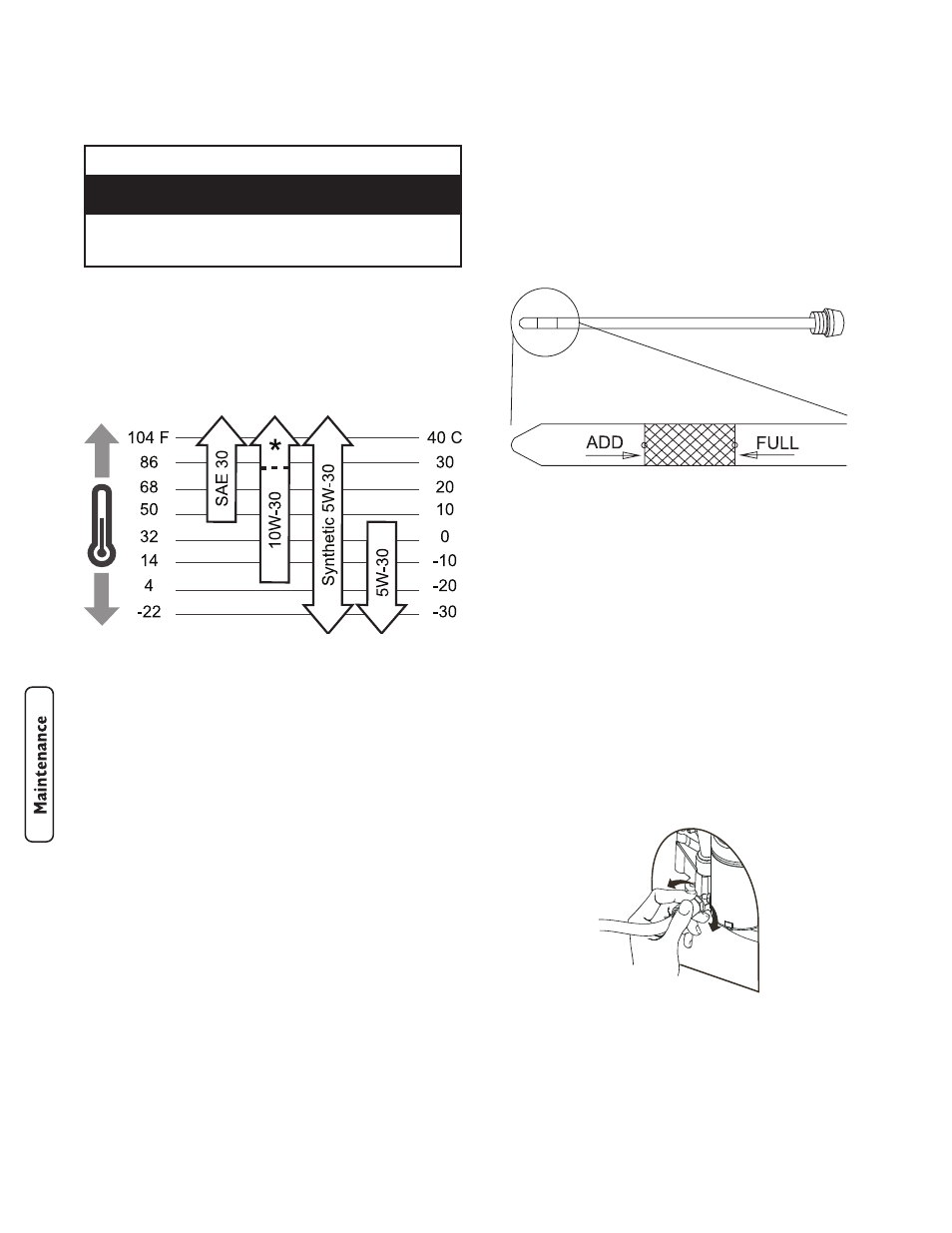

Choose a viscosity according to the following table:

*Check oil level frequently at higher temperatures.

NOTE: Synthetic oil meeting ILSAC GF-2, API

certification mark and API service symbol with “SJ/CF

ENERGY CONSERVING” or higher, is an acceptable oil at

all temperatures. Use of synthetic oil does not alter

required oil change intervals.

SAE 30: 40 °F and higher (5 °C and higher) is good for all

purpose use above 40°F, use below 40°F will cause hard

starting.

10W-30: 0 to 100 °F (-18 to 38 °C) is better for varying

temperature conditions. This grade of oil improves cold

weather starting, but may increase oil consumption at

80°F (27°C) or higher.

Synthetic 5W-30: -20 to 120 °F (-30 to 40 °C) provides

the best protection at all temperatures as well as

improved starting with less oil consumption.

5W-30: 40 °F and below (5 °C and below) is

recommended for winter use, and works best in cold

conditions.

Checking and Adding Oil

Oil level should be checked prior to each use or at least

every 8 hours of operation. Keep oil level maintained.

1.

Make sure unit is on a level surface.

2.

Remove roof (see Removable Roof and Battery

Access section).

3.

Remove oil fill cap/dipstick and wipe clean with cloth.

4.

Verify oil level is at the FULL mark on dipstick

(Figure 14).

5.

If needed, slowly pour oil into oil fill opening.

RECHECK oil level. DO NOT overfill.

6.

Replace and tighten dipstick.

7.

Replace roof.

Changing Engine Oil and Filter

Remove the two screws from each plastic access cover

and remove both access covers from the two sides of the

generator enclosure.

Changing Oil

1.

Slide oil drain tube from hose clamp and place oil

drain tube into approved container.

2.

Push in and rotate oil drain fitting 1/4 turn

counterclockwise. Slowly pull outward until oil starts

draining (Figure 15). DO NOT pull oil drain fitting

off.

Figure 15 — Oil Drain Fitting

Figure 14 — Oil Fill Range

•

DO NOT expose generator to excessive moisture, dust, dirt, or

corrosive vapors.

•

DO NOT insert any objects through cooling slots.

Improper treatment of generator can damage it and

shorten its life.

CAUTION