Step-by-step how to do it – Bryan Boilers Bryan Knockdown CLM-150 36 User Manual

Page 3

Bryan Knockdown

TM

boilers

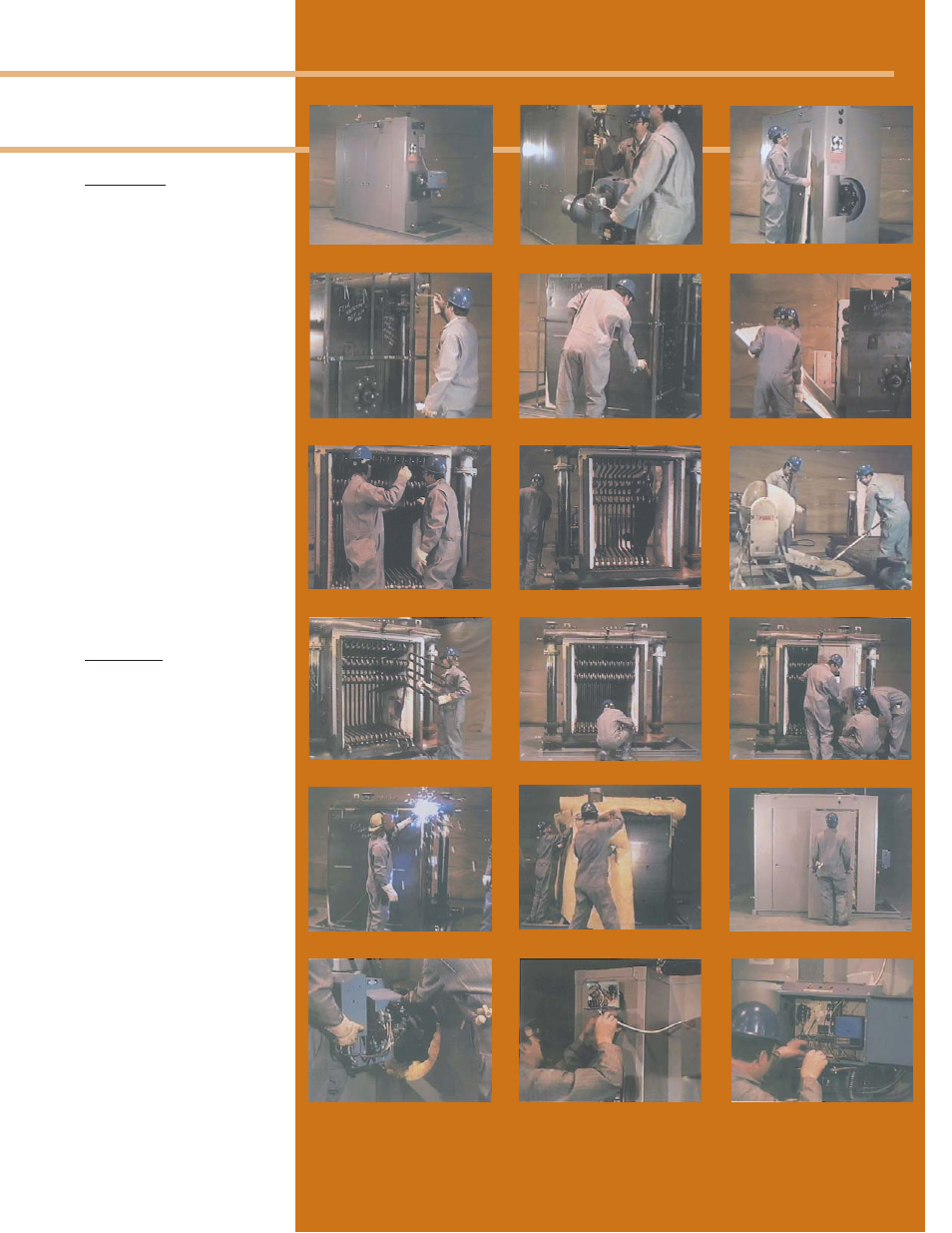

Disassembly

1. RV Series boiler shown.

This is KD-4 condition as

the boiler is delivered to the

job site.

2. After unbolting clips remove

burner.

3. Remove control devices,

gauges and valves, jacket

access doors and panels.

Jacket panels are fastened

with single screws.

4. Flanges are color coded

with their mates to make

correct reassembly easy.

White stripes guide accu-

rate realignment.

5. Jacket frames are tack

welded and coded for easy

reassembly. Break tack

welds and remove frame.

6. Remove tube panels (secured

by bolts and angles) tube

clamps, and back flue panel

(tack welded).

7. Remove baffles and with tube

puller furnished, remove

tubes. Remove flue collector

end panels.

8. Remove bolts holding up-

per tube header and remove

pressure vessel assembly

using permanent lift lugs on

the assembly.

Reassembly

9. Transport components

through doors to boiler site

for reassembly. Install

monoblock insulation in floor

frame, mix cement reinforced

with stainless steel needles,

pour refractory base in floor

frame.

10. Matching flange colors reas-

semble pressure vessel. Pre-

pare tube holes and install

tubes.

11. Install tube clamps. Install flue

collector panels, position

tube panel frame and weld

into place.

12. Insert baffles and install flue

collector back and side

panels. Install flue collector

top. Install tube panels.

13. Seal weld entire flue collec-

tor to prevent flue gas leaks.

Reassemble jacket frame-

work following color codes

and aligning tack welds, then

weld into place.

14. Apply insulation all around

and secure.

15. Attach jacket panels to frame-

work.

16. Install burner, pack around

head with ceramic blanket.

17. Install control devices using

pre-drilled holes and outlet

openings. Install control

panel.

18. Wire controls into burner

panel.

Step-by-step

how to do it

16

10

11

12

8

9

7

4

5

6

3

1

2

17

18

13

14

15