Service (cont.), Adjustments, Wiring diagram – Bunn WDG-2 User Manual

Page 18: Pages 24 & 25) and reinstall wires

18

SERVICE (cont.)

Motor (cont.)

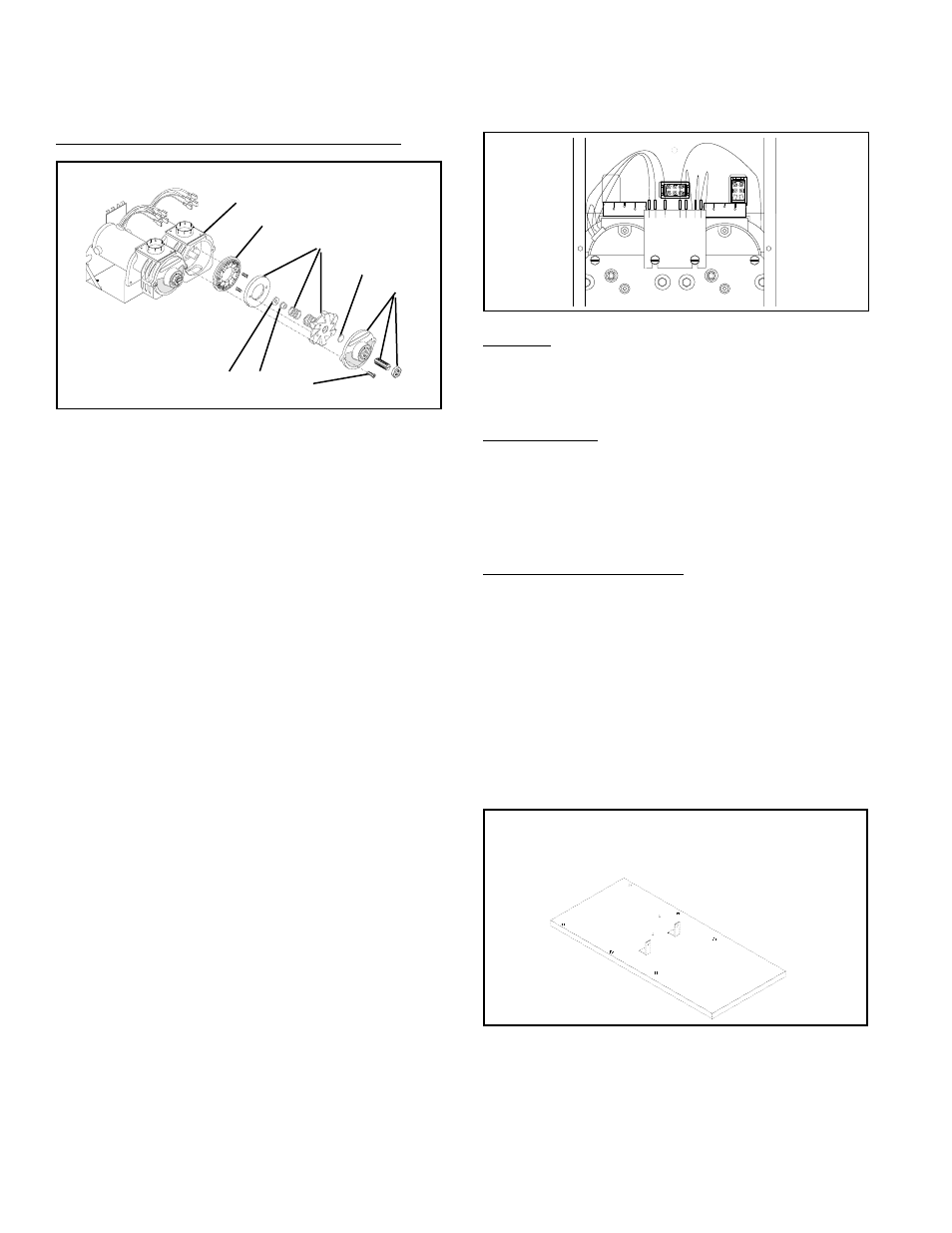

Removal and Replacement - GRIND CHAMBER

H

G

D

C

B

F E A

COARSE FINE

T

H

O

R

O

UG

HLY

CLEAN GRIND C

HA

M

B

E

R

B

E

F

O

R

E

R

E

A

S

S

E

M

B

L

Y

E

M

PT

Y H

OPPER BEFORE

RE

M

O

V

IN

G

T

H

IS

C

O

V

E

R

.

NO

TI

C

E

COARSE FINE

C

O

A

R

S

E

- FI

NE

BU

N

N

COARSE FINE

T

H

O

R

O

UG

HLY

CLEAN GRIND C

HA

M

B

E

R

B

E

F

O

R

E

R

E

A

S

S

E

M

B

L

Y

E

M

PT

Y H

OPPER BEFORE

RE

M

O

V

IN

G

T

H

IS

C

O

V

E

R

.

NO

TI

C

E

COARSE FINE

C

O

A

R

S

E

- FI

NE

BU

N

N

20667.0000

20666.0000

P744

1.

Remove the two 1/4"-20 screws (A) holding the

front cover (B) to the burr housing (H). Carefully

remove the burr housing front cover with adjust-

ing screw and nut. Inspect adjusting screw to

see if worn.

Replace if excessively worn or

damaged.

2.

Remove load disc (C) from burr auger rotor/

spring assembly (D). Inspect disc to see if worn.

Replace if excessively worn or damaged.

3.

Carefully remove burr auger rotor/spring assem-

bly (D) from burr housing (H). Inspect burr for

wear.

Replace if excessively worn or damaged.

4.

Remove bushing (E) and washer (F) from motor

shaft.

5.

Remove the two 1/4"-20 screws attaching sta-

tionary burr (G) to burr housing (H). Remove

and inspect burr for wear.

Replace if excessively worn or damaged.

6.

Inspect the grind chamber and remove any for-

eign materials. The burrs will not properly seat

in the chamber if any material or coffee particles

remain.

7.

Reinstall the stationary burr (G), washer (F),

bushing (E), burr auger rotor/spring

assembly(D), load disc(C) and burr housing front

cover(B) with adjusting screw and nut to the burr

housing(H).

8.

Refer to

Adjustments

section (page 7) to vary

the grind dispensed.

Motor Circuit Assembly

Location:

The motor circuit assembly is located on the

rear of motor mounting bracket.

P750

Test Procedure:

1.

The motor circuit assembly is a line filter for

motor electrical noise.

2.

If the timer settings are erratic or change replace

the motor circuit assembly board.

Removal and Replacement:

1.

Remove all wires.

2.

Loosen the two #10-32 slotted hex head screw

and lift motor circuit assembly off.

3.

Install new motor circuit assembly between head

of screws and external tooth lockwashers.

Tighten screws.

4.

Refer to

Wiring Diagram

(pages 24 & 25) and

reinstall wires.