Electrical connections, Us wiring – Bosch AE115 User Manual

Page 5

•

Do not use plastic piping within 3 feet on either side of heater.

•

Use Teflon tape for sealing pipe threads. Do NOT use pipe dope.

•

Remember to keep the hot water pipe runs as short as possible.

•

After the heater has been plumbed, and before you wire it, flush it with water to remove any debris

or loose particles. Heater must be full of water and air purged before power is turned on. Failure to

do so may make the heater inoperable.

•

The inlet and outlet connections are clearly marked on the heater. They each have a ¾ inch NPT

connector.

•

Check the pressure of the main water supply. To operate correctly, th e heater needs the following

running pressures:

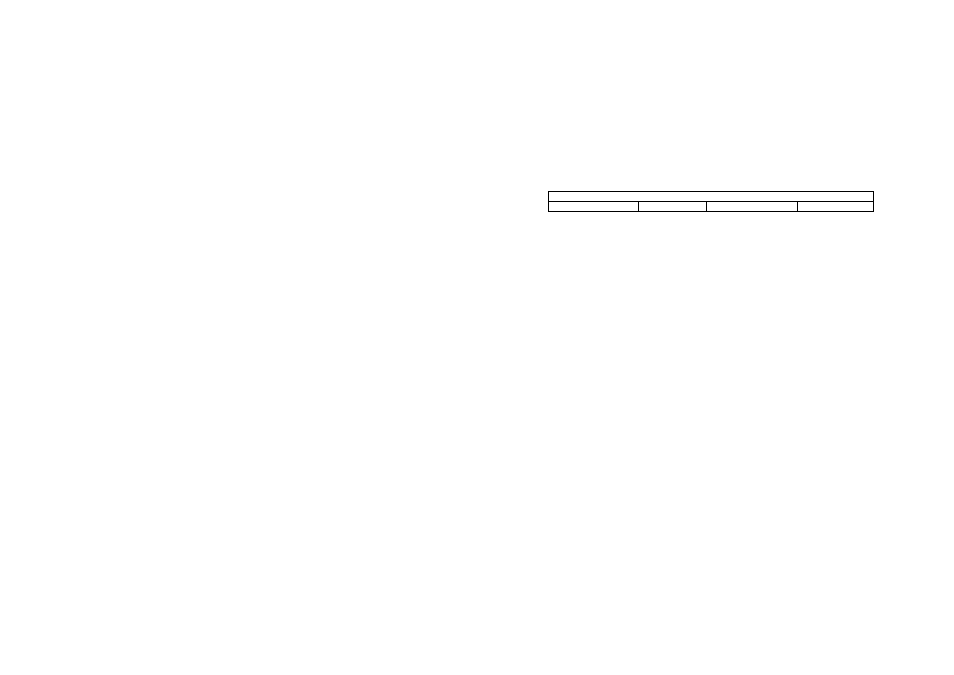

Recommended water pressures

Min water pressure

15 psi (1 Bar)

Max water pressure

150 psi (10 Bar)

Electrical connections

WARNING

The unit must be wired by a qualified electrician, in accordance with the current version of the National

Electrical Code US) or Canadian Electric Code (Canada).

IMPORTANT

When the heater is not within sight of the electrical circuit breakers, a circuit breaker lockout or additional

local means of disconnection for all non-grounded conductors must be provided that is within sight of the

appliance. (Ref NEC 422.31.)

IMPORTANT

As per the Canadian Electrical Code, C22.1-02 Section 26-744, an auxiliary terminal block must be fitted

to the heater before connecting to the elect

rical supply. This is available as a kit from Bosch

Thermotechnology Corp. Part Number “AE Canada Kit”. (Contact 866-642-

3199).

US wiring

•

The minimum recommended wire size is 8 AWG. (The terminal block will accept cables up to 6

AWG size.)

•

The cable entry is via the 1 ¼ inch cable entry hole on the bottom right hand edge of the back plate.

•

Strip back the insulation on the power wires about ½ inch. Connect the live wires to the terminals

marked “L1” and “L2.” There are two pairs of live wires in the AE115 an d three pairs of live wires in

the AE125. (See Diagrams 2 or 3 on page 6).

•

Any insulation on the ground wires should be stripped back about ¾ inch. The ground leads must be

connected to the pillar terminal marked “GR”. (See Diagrams 2 and 3, Page 6).

•

Make sure the terminal block screws are tightened securely. Loose connections can cause wires to

heat up.

•

Make sure that the ground wires are wrapped around its terminal stud and into the saddle washer.

The nut should be tightened securely.

•

Attach the front cover and tighten the retaining screws.

5