Bryan Boilers HE-CLM300-W-FDG User Manual

Page 2

Bryan HE-CLM Series Gas Fired Flexible Tube Boilers

Form No. 6700

©2007 Bryan Steam LLC

Printed in USA

57-8782

Effi cient Water Tube Design

The Bryan Flexible Water Tube provides for extremely fast

internal circulation for maximum heat transfer and operating

effi ciency.

No “Thermal Shock”

The fl exibility of the bent water tube design eliminates all

possible damage from “Thermal Shock” and from stresses

caused by poor or unequal internal circulation. This is particu-

larly important with forced hot water heating systems designed

for higher temperatures and greater temperature drops.

Natural Internal Circulation

The water tube design and the large water leg downcomers

provide adequate internal circulation without concern over ex-

terior pumping conditions. Low pressure drop through boiler.

Compact — Minimum Floor Space

Requires less fl oor space than most boilers — minimum

boiler room size.

Shipped completely assembled and wired.

Tubes are easily removable and replaceable, requiring little

service space.

Combination thermometer and pres-

sure gauge, ASME-rated boiler relief

valve, water temperature control (240°F

max. std.), high limit control, probe

LWCO. Electronic combustion safety

control, automatic operating gas valve,

safety gas valve, pilot solenoid valve,

pilot ignition assembly, main manual

gas shut-off valve, pilot cock, pilot

and main gas pressure regulators, air

safety switch, control panel, all controls

installed and wired.

Dimensions and specifi cations are subject to change without notice. Consult factory for certifi ed dimensions.

Bryan Steam LLC — Leaders Since 1916

783 N. Chili Ave., Peru, Indiana 46970 U.S.A.

Phone: 765-473-6651 • Internet:www.bryanboilers.com

Fax: 765-473-3074 • E-mail: [email protected]

OPTIONAL CONSTRUCTION:

Optional construction to ASME Power

Boiler Code requirements for tempera-

tures exceeding 240°F and/or pres-

sure exceeding 160 psi to maximum

of 285°F operating and 300°F design

temperature and 250 psi.

When ordering, please specify:

1. Boiler

size

2. Supply

and

return

temperatures

required

3. Boiler relief valve setting

4. Type of fuel: natural, LP,

or other gas

5. Gas BTU content, specifi c

gravity and pressure

available

6. Electric

power

voltage,

phase and frequency

7. Optional extra equipment

or

construction

8. Special

approvals

required

(UL, CUL, CSD-1, FM, or IRI)

9. Altitude

OPTIONAL EQUIPMENT:

1. Manual reset high limit control

2. Manual reset low water cutoff

3. Auxiliary low water cutoff

4. Combination low water cutoff

and

feeder

5. Alarm bells or horns

6. UL, CUL, CSD-1, FM, IRI or other in-

surance approved control systems

7. Control panel mounted on boiler

8. Indicating lights, as desired

9. Lead-lag systems for two or more

boilers with or without outdoor

reset

control

STANDARD EQUIPMENT:

Bryan HE-CLM Series Boilers Standard and Optional Equipment

10. Draft control system

11. Special construction

and knocked down

NOTE: * Gas train and control location dimensions will vary depending on job specifi cations and conditions.

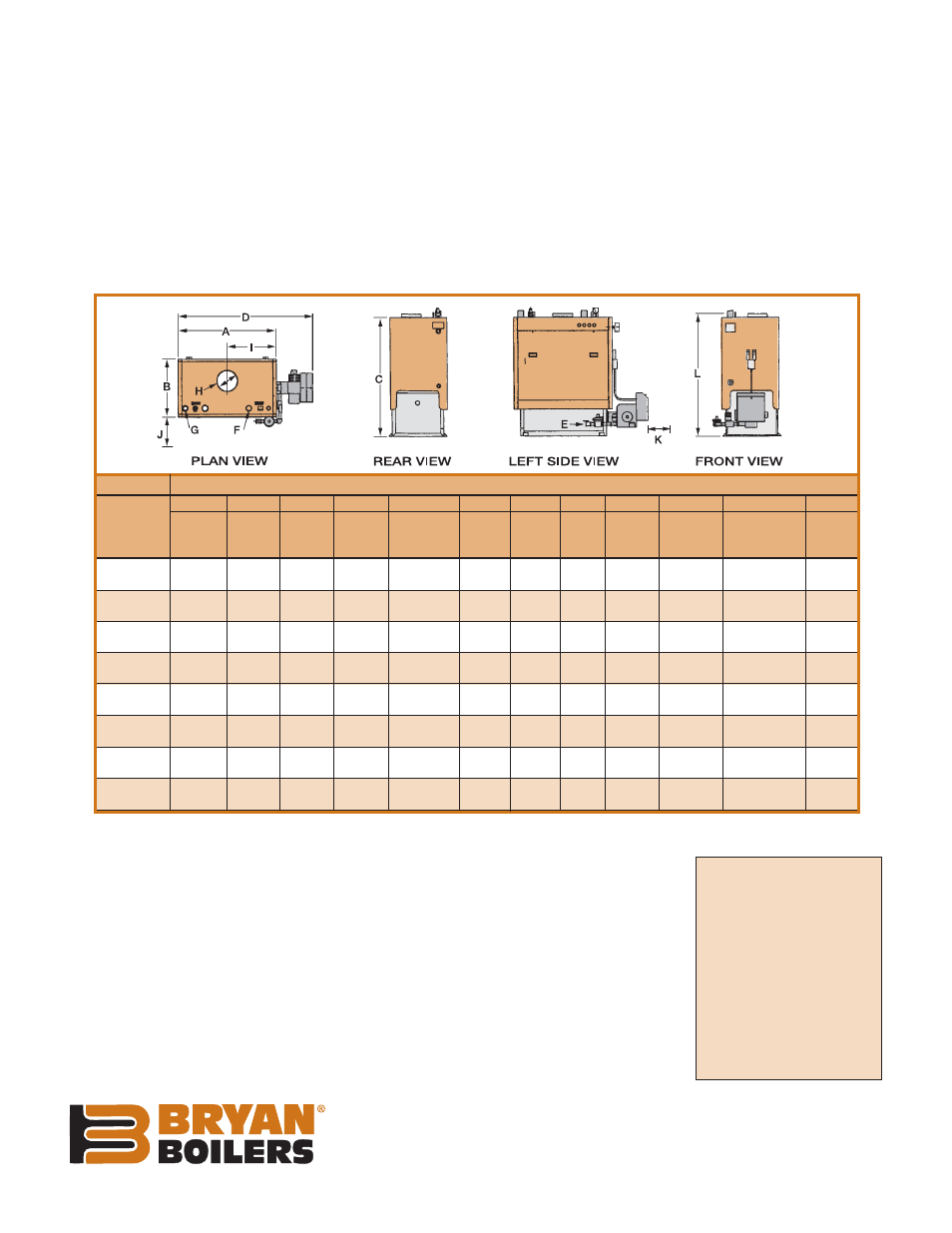

BOILER DIMENSIONS in inches (cm)

A

B

C

D

E*

F

G

H

I

J

K

L

BOILER

Length

Width

Height

Overall

Gas Train

Supply Return

Flue

Flue

Min.

Tube

Clearance

for

Floor

to

MODEL

Of

Outside

Over

Length

Connection Nozzle Nozzle Size Location

Removal

Servicing

Flow

NUMBER

Jacket

Jacket

Jacket

Clearance

Burner

Nozzle

HE-CLM90-W

41

7

/

16

34

5

/

8

72

1

/

16

69

7

/

16

1 NPT

3 NPT

3 NPT

10

20

11

/

16

30 36

76

3

/

16

(105.24) (87.94) (180.03)

(176.98) (2.54)

(7.62) (7.62) (25.40) (52.54) (76.2)

(91.44) (193.51)

HE-CLM120-W

50

11

/

16

34

5

/

8

72

1

/

16

78

11

/

16

1

1

/

4

NPT

3 NPT

3 NPT

10

25

5

/

16

30 36

76

3

/

16

(128.74) (87.94) (180.03)

(199.86) (3.18)

(7.62) (7.62) (25.40) (64.29) (76.2)

(91.44) (193.51)

HE-CLM150-W

59

11

/

16

34

5

/

8

72

1

/

16

87

11

/

16

1

1

/

2

NPT

3 NPT

3 NPT

12

29

13

/

16

30 36

76

3

/

16

(151.60) (87.94) (180.03)

(212.72) (3.81)

(7.62) (7.62) (30.48) (75.72) (76.2)

(91.44) (193.51)

HE-CLM180-W

69

1

/

8

34

5

/

8

72

1

/

16

97

1

/

8

2

NPT

3 NPT

3 NPT

14

34

9

/

16

30 36

76

3

/

16

(175.57) (87.94) (180.03)

(246.69) (5.08)

(7.62) (7.62) (35.56) (87.78) (76.2)

(91.44) (193.51)

HE-CLM210-W

78

3

/

8

34

5

/

8

72

1

/

16

106

3

/

8

2 NPT

3 NPT

3 NPT

14

39

3

/

16

30 36

76

3

/

16

(199.07) (87.94) (180.03)

(270.19) (5.08)

(7.62) (7.62) (35.56) (99.53) (76.2)

(91.44) (193.51)

HE-CLM240-W

88

34

5

/

8

72

1

/

16

116

2 NPT

3 NPT

3 NPT

16

44

30 36

76

3

/

16

(223.52) (87.94) (180.03)

(294.64) (5.08)

(7.62) (7.62) (40.64)

(111.76) (76.2)

(91.44) (193.51)

HE-CLM270-W

97

34

5

/

8

72

1

/

16

125

2 NPT

3 NPT

3 NPT

16

48

1

/

2

30 36

76

3

/

16

(246.38) (87.94) (180.03)

(317.50) (5.08)

(7.62) (7.62) (40.64)

(123.19) (76.2)

(91.44) (193.51)

HE-CLM300-W

106

5

/

8

34

5

/

8

72

1

/

16

134

5

/

8

2

1

/

2

NPT

3 NPT

3 NPT

16

53

3

/

16

30 36

76

3

/

16

(270.82) (87.94) (180.03)

(341.91) (6.35)

(7.62) (7.62) (40.64) (40.64) (76.2)

(91.44) (193.51)