Gearbox disassembly, Gearbox disassembly -11, Maintenance – Blue Rhino TM72 User Manual

Page 151

MAINTENANCE

TM60/72/84/100 02/11

Maintenance Section 5-11

© 2011 Alamo Group Inc.

MAINTENANCE

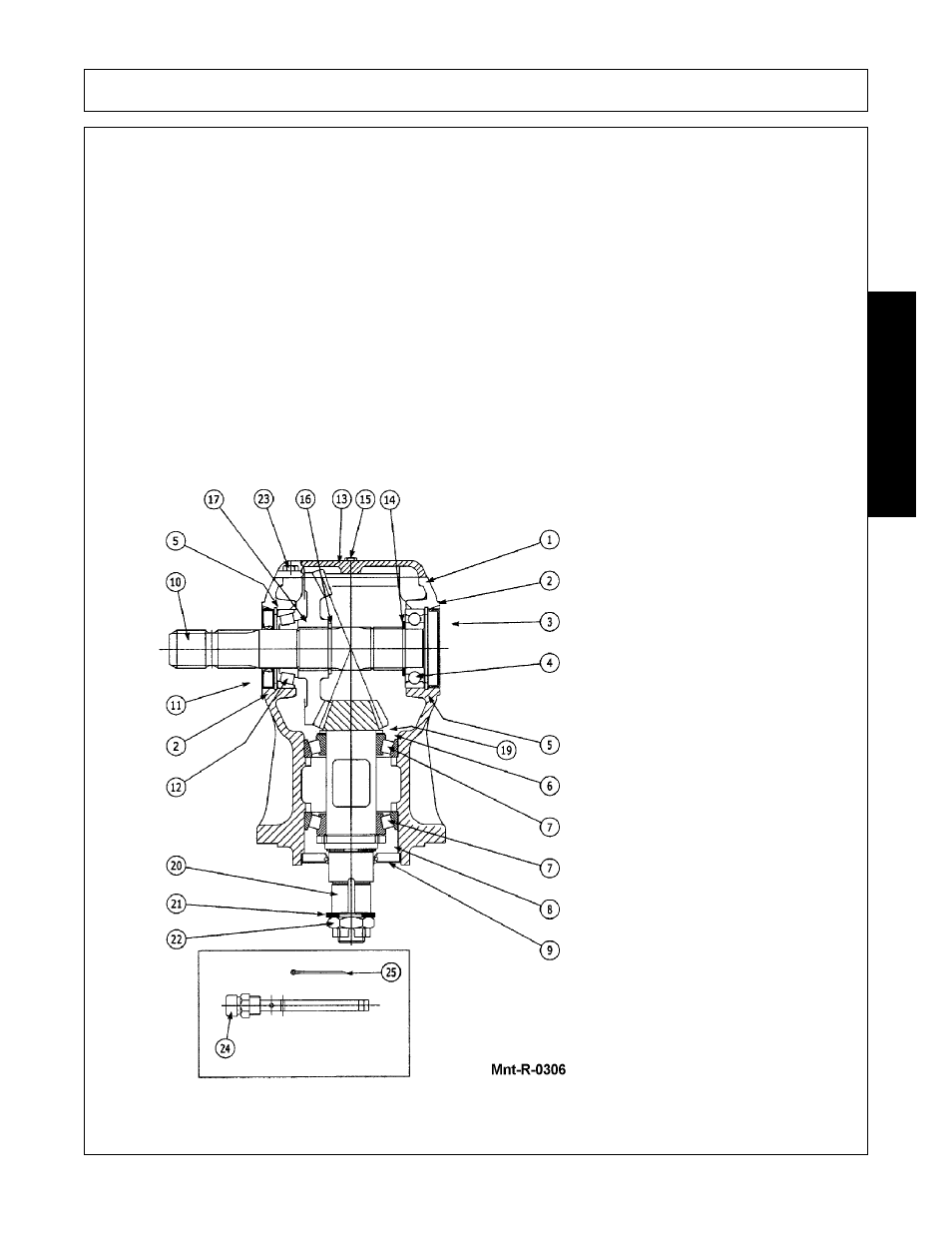

GEARBOX DISASSEMBLY

1. Remove 4 Cover bolts (23) and drain oil from housing.

2. Remove all grease seals (9), (3) and (11) by using screw driver to puncture steel case and then pry out

each seal. Use caution not to scratch housing bores during removal.

3. Remove input shaft retaining rings (2) from both sides of gear housing(1).

4. Remove input shaft (10) by hitting on drive end of shaft. This will remove shaft (10) and rear ball bearing.

(4). Note: Be aware of position of shims (5) and (14) for later use when assembling gearbox.

5. Remove gear (17) and bearing cup and cone(12).

6. Output shaft is retained in housing by crimp nut on bottom end of shaft. Insert screw driver into groove in

output shaft to straighten out crimped portion of locknut (8). Remove locknut (8) from output shaft (20).

7. Install nut (22) on end of output shaft (20). Drive output shaft (20) out of housing (1) by hitting on end of

shaft. Use wood block so nut or threads are not damaged. Shaft will come out top of housing and will have

bearing cone under gear.

8. Remove bearing cone (7) from output shaft (20). Note: Keep any shims (6) between bearing (7) and gear

for later installation.

9. Remove both bearing cones from housing.

1.

1

Housing, Gearbox

2.

2

Snap Ring

3.

1

Cap Ring

4.I

1

Bearing Ball

5.

2

Shim

6.

1

Shim Kit

7.

2

Bearing

8.

1

Locknut

9.

1

Seal, Output

10.

1

Shaft, Input

11.

1

Seal, Input Shaft

12.

1

Bearing

13.

1

Cover, Gearbox

14.

1

Shim

15.

1

Plug, 3/8”

16.

1

Snap Ring

17.

1

Gear, Crown

18.

1

Plate

19.

1

Shim

20.

1

Shaft, Pinion

21.

1

Washer, External Tooth

22.

1

Nut, Castle

23.

4

Bolt. Metric

24.

1

Plug, Breather Dipstick

25.

1

Cotter Pin