Grinder assembly – Bosch 1894-6 User Manual

Page 7

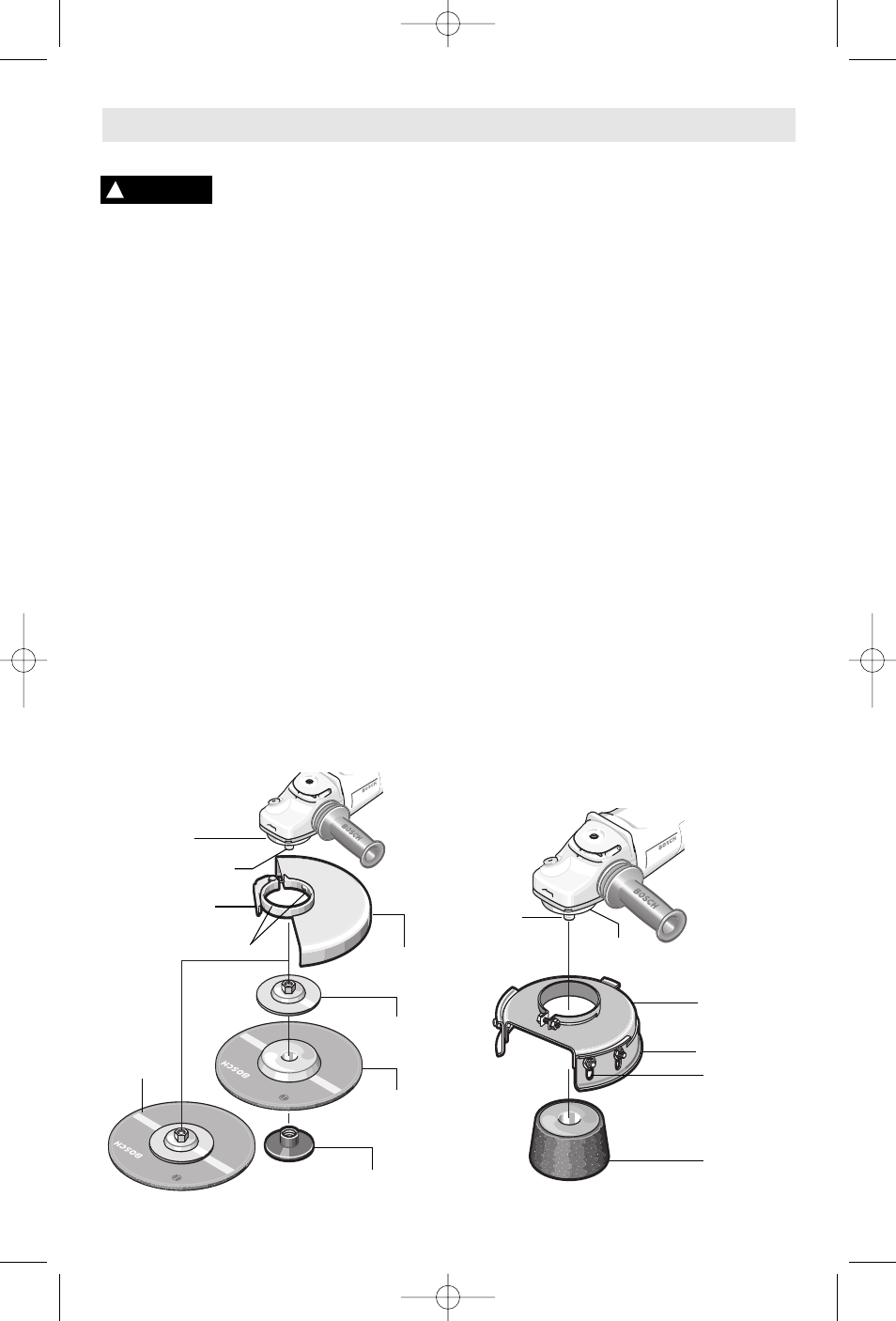

Grinder Assembly

-7-

WHEEL GUARD INSTALLATION

Use wheel guard with disc

grinding wheels. Always

close the latch to secure the guard. Keep the

guard between you and the wheel. Do not

direct guard opening toward your body.

The position of the guard can be adjusted to

accommodate the operation being performed.

To attach wheel guard DISCONNECT tool

from power source.

Open guard release/lock latch and position

guard on spindle neck so that the two bumps

on guard, line up with the two notches on the

spindle neck.

Rotate guard either direction to desired

position, and close latch to secure guard in

place.

TO REMOVE GUARD:

Open guard

release/lock latch, rotate guard until the two

bumps on guard line up with the two notches

on the spindle neck, and lift guard off the

spindle neck.

LOCK NUT AND BACKING FLANGE

Your tool is equipped with a threaded spindle

for mounting accessories. Always use the

lock nut and backing flange that has same

thread size as spindle.

DISC GRINDING WHEEL ASSEMBLY

Disconnect tool from power source. Be sure

that wheel guard is in place for grinding.

When using spin-on grinding wheels, thread

directly onto the spindle.

When using mounting wheels, thread

BACKING FLANGE onto spindle, then place

GRINDING WHEEL on the spindle. Thread

on the lock nut and tighten nut using a lock

nut wrench provided with adapter kit, while

holding the spindle lock in.

TO REMOVE: Reverse procedure.

CUP GRINDING WHEELS

Use cup grinding wheels for heavy-duty stock

removal of metals, concrete and stone.

ADJUSTABLE CUP

WHEEL GUARD INSTALLATION

Open the guard clamp and fit it on the

mounting flange then secure by tightening

the clamp screw. ALWAYS HAVE THIS

GUARD ATTACHED WHEN USING CUP

GRINDING WHEELS

The adjustable guard allows you to lower or

raise the guard’s shell. TO ADJUST: Loosen

the four bolts on the shell, and secure the

shell for 1/4” wheel exposure for maximum

safety.

ATTACHING CUP GRINDING WHEEL

Thread the cup grinding wheel on the spindle

shaft CLOCKWISE. Press in the spindle lock

button and turn the cup grinding wheel until

the lock button engages, then tighten the

wheel securely by hand.

TO REMOVE: Reverse procedure.

!

WARNING

BACKING

FLANGE

LOCK NUT

WHEEL

GUARD

DISC

GRINDING

WHEEL

SPIN-ON

GRINDING

WHEEL

SPINDLE

MOUNTING

FLANGE

BUMPS

GUARD

RELEASE / LOCK

LATCH

BOLT

ADJUSTABLE

GUARD

CUP

GRINDING

WHEEL

SHELL

SPINDLE

MOUNTING

FLANGE

BM 1609929H54 08-06 8/3/06 11:44 AM Page 7