DuraVent PolyPro User Manual

Page 4

4

LISTING

Listed to ULC S636

Rated Class IIA, IIB, and IIC vent system

maximum temperature 230°F (110 °C)

maximum positive pressure 15 in-w.c.

Massachusetts Plumbers Board,

# G1-0811-42

APPLICATION

ANSI Category II and IV gas-burning

appliances

Appliances specifically tested and listed to

use M&G DuraVent PolyPro Venting

PERMITS

Check with your local Building Official, Fire

Official, or other authority having jurisdiction

regarding permits, restrictions, and

installation inspections in your area.

GENERAL INSTALLATION NOTES

Read these instructions before beginning.

You must use only authorized M&G DuraVent

PolyPro vent parts, or other parts specifically

authorized in these instructions and/or listed

by the appliance manufacturer in order to

maintain a safe, approved system.

•

Do not fill any air space clearance

(Table 1) with insulation.

•

Do not mix parts or try to match with

other products or use improvised

solutions.

•

Do not install damaged or modified

parts.

•

Use soapy water to lubricate gaskets.

•

Never use Petroleum base lubricants.

If these directions and those of the appliance

manufacturer differ, follow the more

conservative requirements. If you have any

questions, contact either your dealer or M&G

DuraVent directly. A venting system must

not be routed into, through, or within any

other vent, such as an existing masonry or

factory-built chimney flue, unless that vent

or chimney is not being used to vent another

appliance and is only used as a conduit for

the gas-vent system. Plastic venting systems

shall not pass through fire rated separations

without approved firestopping.

Refer to the appliance manufacturer's

instructions for maximum and minimum

vent lengths permitted with your specific

appliance model. This information should

include guidance on the maximum number

of elbows and related pressure-drops. The

total vent length from the appliance to

the termination shall not be greater than

specified by the appliance manufacturer.

If specific guidance is not offered by the

appliance manufacturer as to Equivalent

Vent Lengths (EVL) for vent components, the

general guidelines in Table 2 can be used.

CONDENSATE DRAIN (Fig.1)

Refer to the appliance manufacturer’s

installation instructions for requirements of

condensate drainage. Ensure proper system

slope for drainage. (Fig.7)

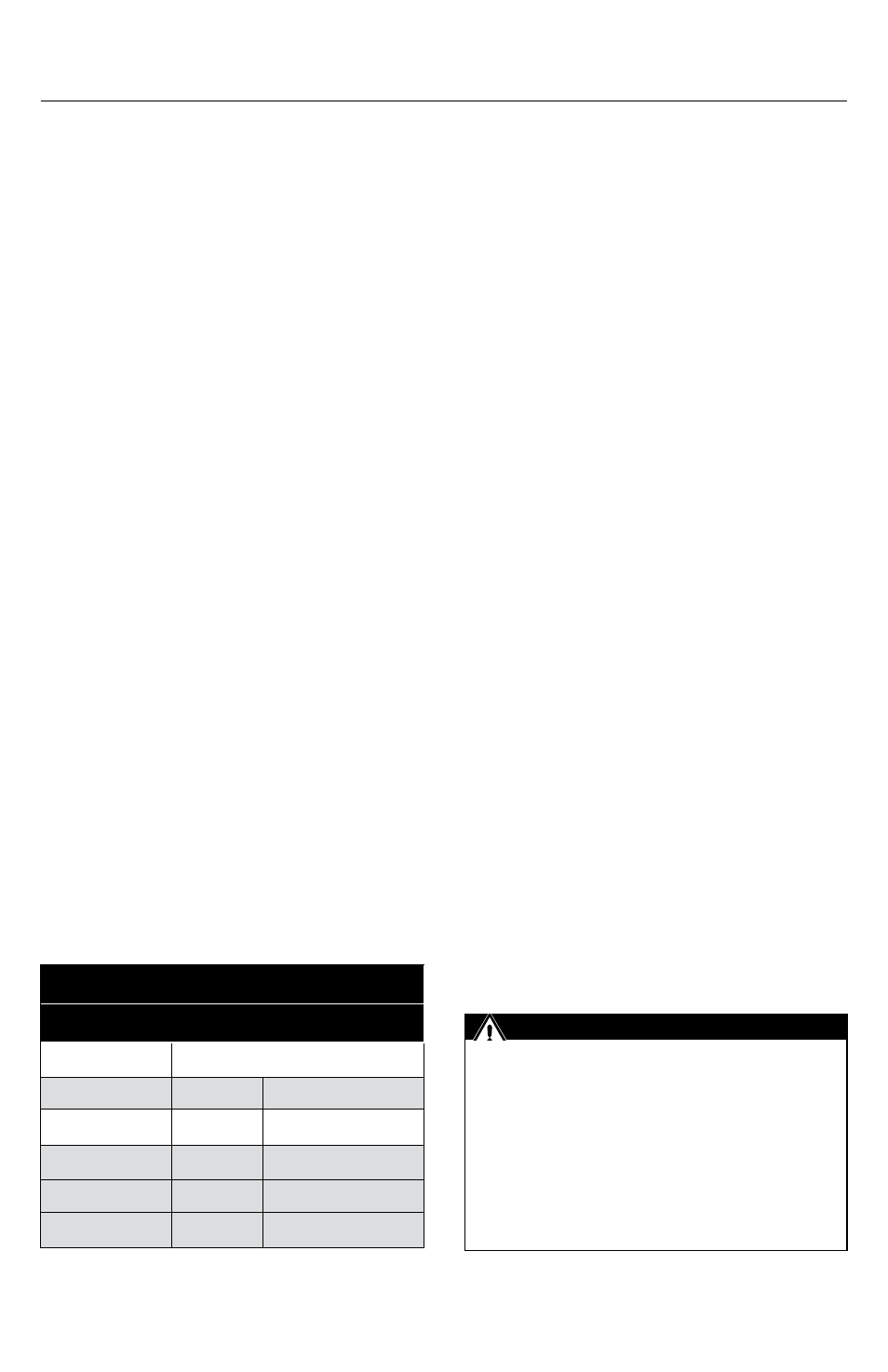

Table 1

Clearance to Combustibles

VENT PIPE ORIENTATION

Single Wall

Vertical

Horizontal

Up to 190°F

0"

0"

Up to 230°F

0"

¼" (6mm) all around

Concentric

Up to 230°F

0"

0"

The vent system must be compliant in

accordance with local code requirements

and appropriate National Codes: In

the US: NFPA 54 / ANSI Z223.1 National

Fuel Gas Code or the International Fuel

Gas Code. In Canada: CAN/CGA-B149.1

Natural Gas Installation Code or CAN/CGA-

149.2 Propane Installation Code.

IMPORTANT