Specifications, Tips and guidelines for effective cleaning – Graymills BTU Benchtop Ultrasonic User Manual

Page 5

795-91322

09/24/08

Graymills Corporation – 3705 N. Lincoln Ave. / Chicago, IL 60613 – Phone: 773.477.4100 Fax: 773.477.8673 –

www.graymills.com

TIPS AND GUIDELINES FOR EFFECTIVE CLEANING

1) Choose a workbasket with the largest openings possible without allowing the parts to fall through.

2) For extremely small parts, a solid bottom basket with weep holes is preferred.

3) If the parts tend to “nest” or stick together, gentle agitation or tumbling will insure that the cleaning fluid reaches all the

surfaces.

4) Hollow or concave parts should be positioned so that they fill and drain completely during the cleaning cycle.

Remember that the ultrasonics can only reach where the cleaning fluid reaches.

5) Choose a detergent or cleaning fluid that is effective against contamination on the parts without damaging the parts or part

surfaces.

Always test a cleaning fluid with a sample part before cleaning a large workload.

6) Use the mildest cleaning fluid that will be effective in your application. Start with the weakest dilution ratio recommended by

the detergent manufacturer and gradually add more concentrate until satisfactory cleaning is obtained.

7) Gentle heating usually improves the cleaning performance. The optimum cleaning range is between 120

°F and 140°F. Higher

temperatures may be required in some applications.

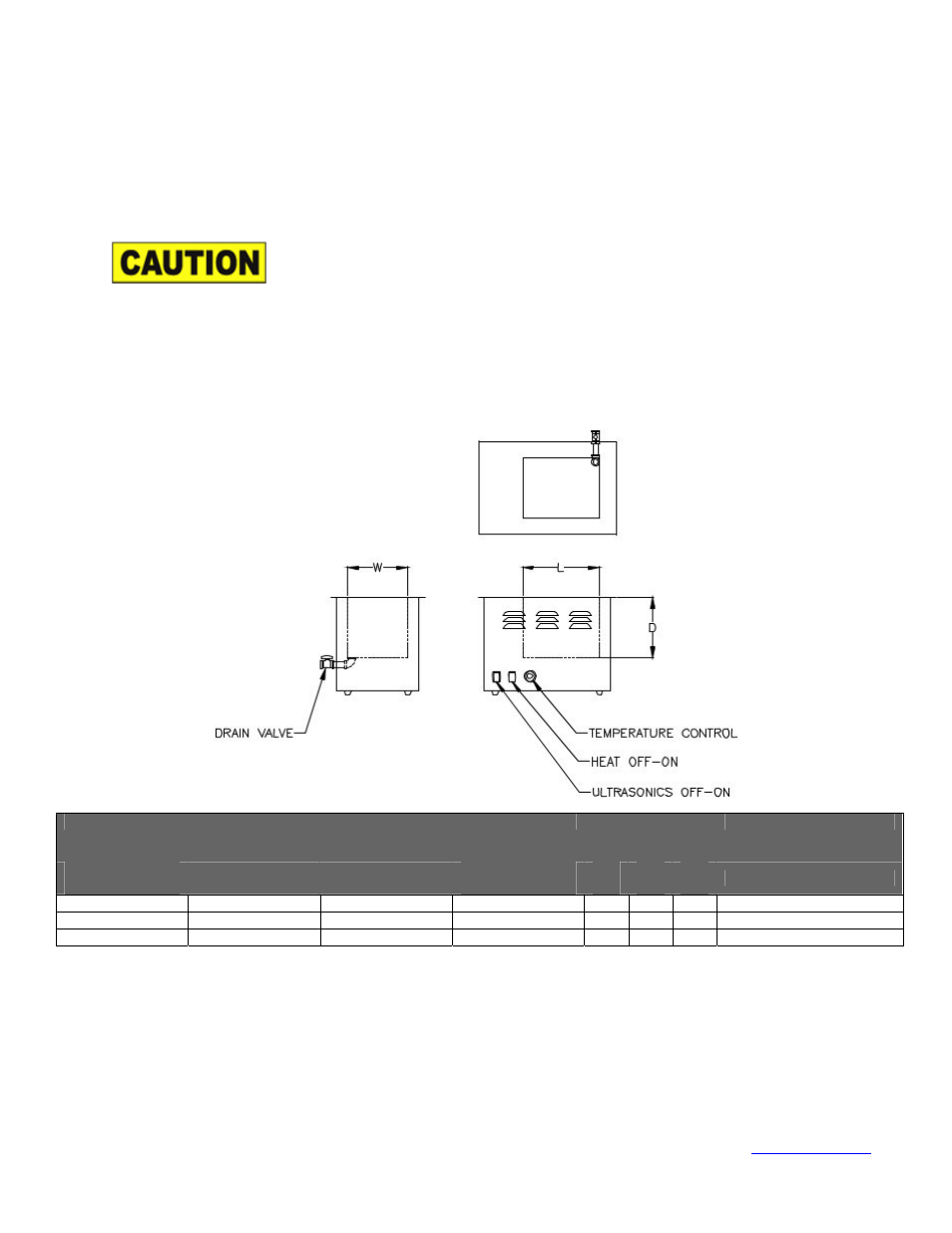

SPECIFICATIONS

Tank

Dimensions

(Inches)

Model

Tank Capacity

Ultrasonic Power

Heater Power

L

W

D

Power Required

BTU-4

4.15 Gal.

250 W.

500 W.

12

8

10

120 V

BTU-7

7.33 Gal.

500 W.

500 W.

14

11

11

120 V

BTU-17

17 Gal.

750 W.

1,000 W.

20

14

14

120 V

Materials of Construction:

Standard Accessories:

Optional Accessories:

Tank: 14 ga. T316L stainless steel

Cabinet: 16 ga. T304 stainless steel

• Adjustable,

thermostatically-controlled

tank heater

•

¾” N.P.T. brass drain valve

•

¼” thick polypropylene tank cover with

handle

•

Stainless steel mesh parts basket

–

5