Checking the volume (calibration) – BrandTech Scientific Dispensette III User Manual

Page 46

46

Depending on use, we recommend that gravimetric testing of the instrument be carried out every 3-12

months. This time frame should be adjusted to correspond with individual requirements. The complete

testing procedure (SOP) can be downloaded at www.brandtech.com. In addition, you can also carry out

function checks at shorter intervals, e.g. dispensing the nominal volume into a volumetric test flask (volu-

metric flask with 3 marks, DAkkS calibrated). For GLP- and ISO-compliant evaluations and documenta-

tion, we recommend the EASYCAL

™

calibration software from BRAND. A demo version can be down-

loaded from www.brandtech.com.

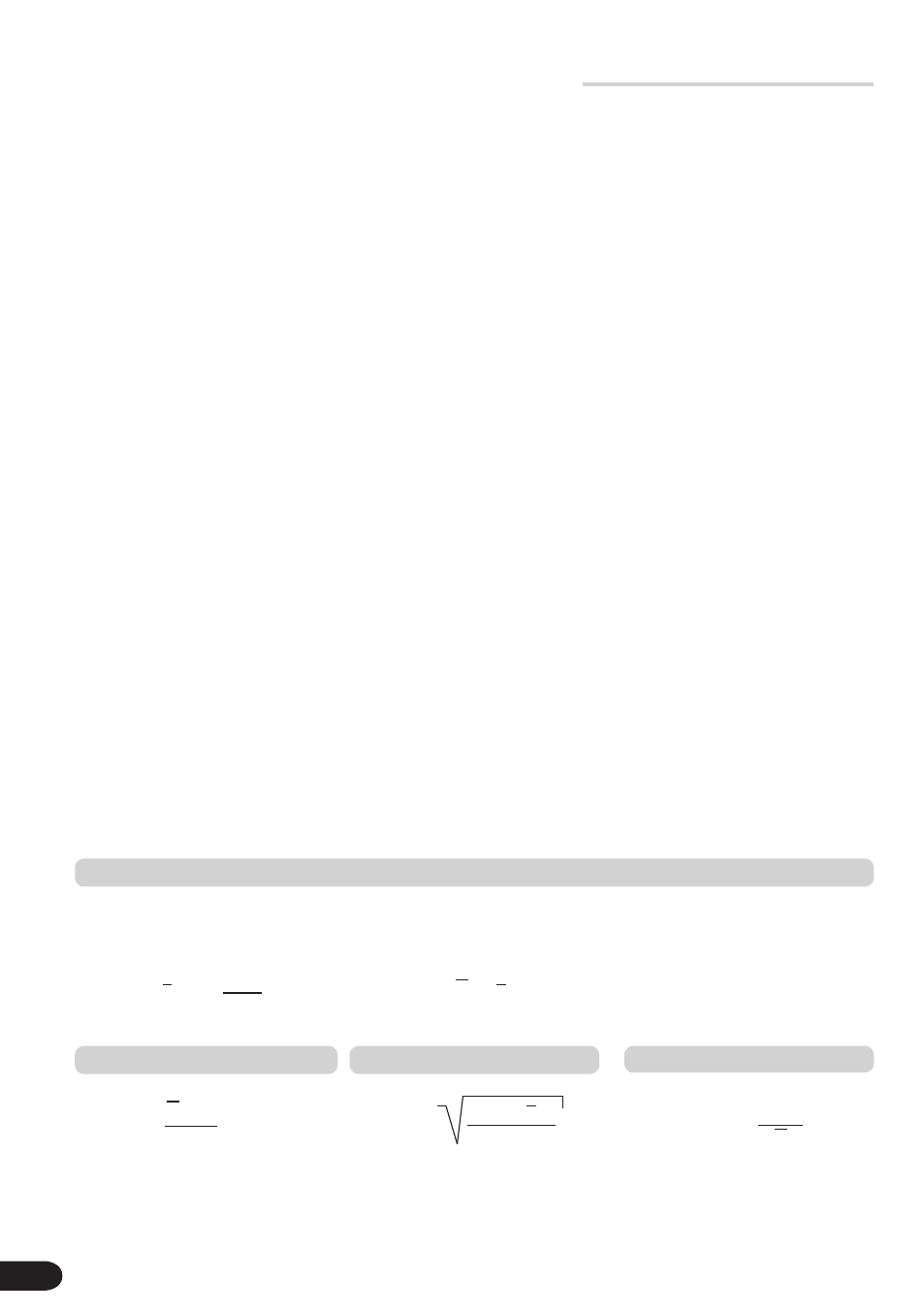

x

i

= results of weighings

n = number of weighings

Z = correction factor

(e. g., 1.0029 µl/mg at 20 °C, 1013 hPa)

V

0

= nominal volume

Mean volume

V – V

0

V

0

A% = · 100

Σ (x

i

– x)

2

n – 1

s = Z ·

Mean value x =

Σ x

i

n

Mean volume V = x · Z

Standard deviation

Coefficient of variation

Checking the Volume (Calibration)

100 s

V

CV% =

Gravimetric volume testing according to DIN EN ISO 8655-6 (for measurement conditions, see 'Error

Limits', page 45) is performed as follows:

1.

Preparation of the instrument

Clean the instrument ('Cleaning', page 48-51),

fill it with distilled H

2

O and then prime it carefully.

2.

Check the volume

a) 10 dispensing operations with distilled H

2

O in

3 Volume ranges (100 %, 50 %, 10 %) are

recommended.

b) For filling pull up the piston gently until the

upper stop of the volume set.

c) For discharge depress piston slowly and

steadily without force until the lower stop.

d) Wipe off the tip of discharge tube.

e) Weigh the dispensed quantity on an analytical

balance. (Please follow the operating manual

of the balance manufacturer.)

f) Calculate the dispensed volume. The Z factor

takes account of the temperature and air

buoyancy.

3.

Calculations

Accuracy