Troubleshooting – Silverline 380W Auto-Feed Screwdriver User Manual

Page 9

8

GB

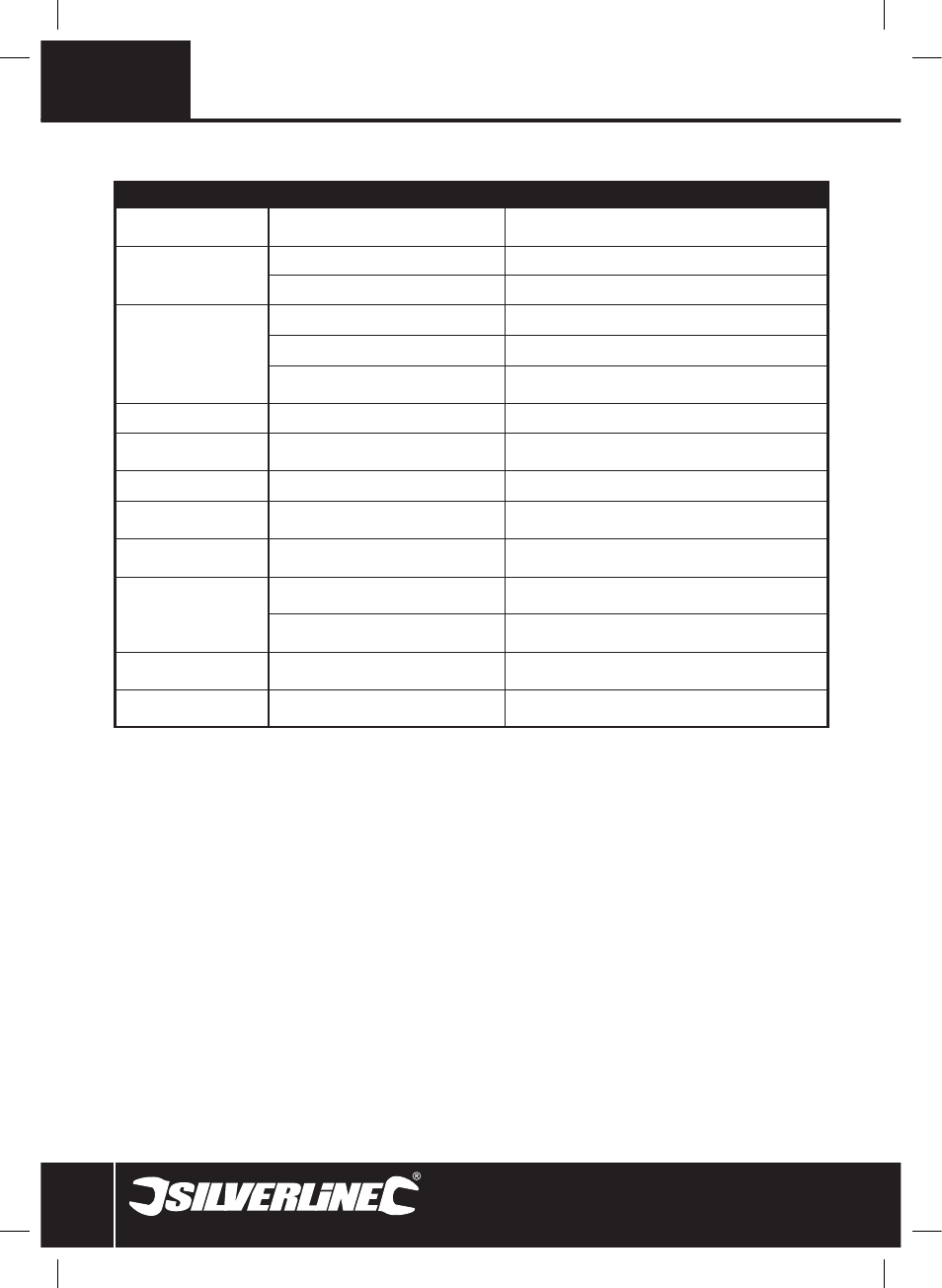

Problem

Possible cause

Solution

Screw is driven too deep into

the workpiece

Depth Adjuster (9) incorrectly set

Move the Depth Adjuster up to reduce the depth

Screw head is not driven fully

into the workpiece

Depth Adjuster incorrectly set

Move the Depth Adjuster down to increase screw depth

Incorrect operation

Plunge the mechanism fully so it is stopped by the Depth Adjuster

Screw belt isn’t feeding

correctly

Belt damaged

Move past damaged part of belt

Incorrectly fitted belt

Make sure belt is correctly fitted at the loading point

Screw Belt Feeder (8) is not allowing free

movement of belt

Check Screw Belt Feeder is not damaged or bent, clean any rough

edges if necessary

Screw not lined up with material

Screw Length incorrectly set

Adjust as per instructions

Screw head getting damaged

Drill at too high a speed

Adjust to lowest speed setting and manually control trigger so speed is

lower for loading screw onto bit

Not driving screws correctly

Non-compatible collated screw belts

Only use compatible collated screws (see Specification)

Cannot use the first screw on

the belt

Mechanism moves to next screw when plunged

Normal operation

Screw driven into material at

an angle

Screw Length incorrect

Adjust Screw Length Knob (2) so Stopper Base (7) holds full length

of screw

Mechanism stiff to operate

Mechanism requires lubrication

Carefully lubricate as per instructions

Screwdriver bit is slightly too large for Screwdriver

Bit Eye (4)

Run tool until the bit rotates easily in the eye

Difficult to adjust for screw

length

Mechanism can be stiff

Apply a small amount of oil or grease

Other abnormal operation

Possible mechanism fault

May require repair or replacement

Troubleshooting

267412_Z1MANPRO1.indd 8

10/09/2013 16:44