Intended use, Unpacking your tool, Before use – Silverline Gravity Feed HVLP Spray Gun User Manual

Page 7: Product familiarisation, Eq-4, En-6

6

GB

Intended Use

• Atomising gravity feed spray gun, powered by filtered compressed air from a

compressor, for spraying of medium viscosity paint and coatings at low pressures

• Compared to conventional spray guns, HVLP (High Volume Low Pressure) spray guns

use a higher volume of air to atomise the paint at much lower air pressures. As a result,

a higher proportion of paint reaches the workpiece surface, and overspray, material

consumption as well as air pollution, are greatly reduced.

Unpacking Your Tool

• Carefully unpack and inspect your tool. Fully familiarise yourself with all its features

and functions

• Ensure that all parts of the tool are present and in good condition. If any parts are

missing or damaged, have such parts replaced before attempting to use this tool

Before Use

Fitting the quick connector

Note: This tool is supplied with two different male airline quick connectors:

EQ-4 – commonly used in Europe

EN-6 – mainly used in the UK

• Please choose the connector that is compatible with the airline system you are using,

and install as outlined below:

1. Apply PTFE tape (not included) to the screw threads of the Quick Connector (7). This

will help to maintain an air tight seal

Note: Apply PTFE tape tightly and in a clockwise direction, so it does not come off when

the thread is screwed into the tool.

2. Remove the protective plug from the air inlet

3. Using a spanner (not included) screw the quick connector into the air inlet located at

the base of the handle

4. Connect to airline, pressurise carefully and carry out a leak check (e.g. by spraying

small amounts of soapy water on to the outside of the connectors)

• Air lines fitted with matching female quick connectors will now be a push fit to the tool

Fitting the paint container

• Before fitting the gravity feed Paint Container (2), pull out the plastic filter element that

sits inside the paint container connection of the spray gun, clean if necessary (see

‘Maintenance’) and inspect for damage

• Fit the paint container by screwing it in to the opening on top of the spray gun. Tighten

by hand

Note: Always inspect the O-ring on the paint container thread, and ensure it is in good

condition. Change if required.

Air supply connection

• This tool should be connected to a clean, dry air supply with water separator and filter

WARNING: Under no circumstances can the spray gun be used in a compressed air system

with integrated oiler.

Note: Achieving a fine spray finish without the use of a high quality separator filter is

virtually impossible.

• Do not allow supply pressure to exceed the maximum stated (see ‘Specifications’)

• Ensure that water is drained from air system daily

• Ensure that all parts of the system (hoses, couplers, etc.) are correctly rated for the air

pressure to be used

• Do not use non-conductive tubing to help prevent build-up of electrostatic charge

Setting the air pressure

• Spray pressure must be set properly to allow for the drop in air pressure between the

regulator and the spray gun

• Use recommended hose diameter to minimise pressure drop and adjust supply air

pressure according to ‘Specifications’

IMPORTANT: To reduce overspray and in order to obtain maximum efficiency, always spray

with the lowest possible air pressure.

Paint preparation

WARNING: Ensure the type of paint, solvent used and the viscosity is suitable for the

material and type of this spray gun.

• Mix, condition and filter the material to be sprayed according to the manufacturer’s

recommendations

• Refer to the manufacturer’s guidelines for storing and disposal of prepared material

Filling the paint container

1. Ensure the spray gun is disconnected from the air supply

2. Unscrew the Paint Container Lid (1)

3. Fill the paint container to the required level

Note: The outside of the paint container features a scale in ml. Never overfill (see

‘Specifications’ for max. paint container capacity).

4. Re-fit the lid of the paint container. Close tightly by hand

Note: The lid features a small hole for pressure equalisation and is therefore not

completely sealed. Take care not to spill material through this hole. Always ensure the hole

remains clean and unblocked.

Adjusting the spray gun

•

Bring the spray gun into the default position:

1. Carefully screw the Knurled Needle Adjustment Screw (4) clockwise until it stops

Note: The needle adjustment screw features a separate knurled locking ring that needs to

be loosened before adjustment is possible. Tighten this ring to lock the needle adjustment.

WARNING: The paint needle can easily be damaged. Be careful not to use too much force.

2. Carefully screw the Knurled Air Adjustment Screw (8) clockwise until it stops

WARNING: DO NOT use too much force, as this may damage the valve seat.

3. Turn the Pattern Adjustment Dial (5) clockwise until it stops

4. Loosen the Air Nozzle Locking Ring (12) about a quarter turn, to allow the Air Nozzle

(11) to be adjusted

Adjust the material output:

1. Connect the spray gun to the air supply

2. Direct the gun towards a large piece of cardboard or similar material

3. Hold the spray gun steady and depress the Trigger (9)

Note: In default position, there should be no material or air output.

4. Turn the Knurled Air Adjustment Screw (8) anticlockwise to set the required air flow

5. Slowly turn the Knurled Needle Adjustment Screw (4) anticlockwise to open the

material flow

6. Adjust until the desired material output is reached

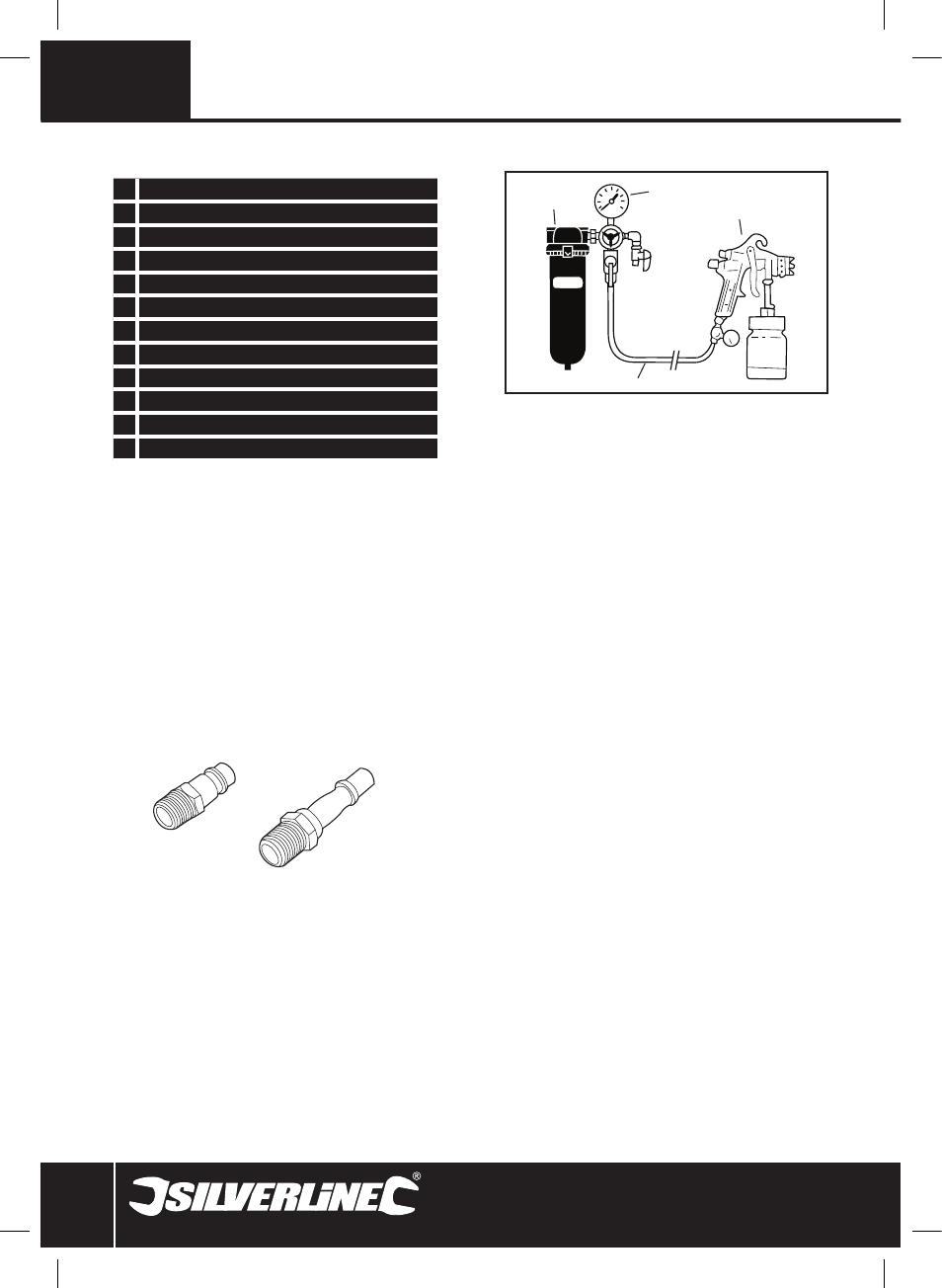

Pressure

regulator

Spray gun

Air line

Separator

filter unit

1

Paint Container Lid

2

Paint Container

3

Hanging Hook

4

Knurled Needle Adjustment Screw

5

Pattern Adjustment Dial

6

Handle

7

Quick Connector

8

Knurled Air Adjustment Screw

9

Trigger

10 Material Nozzle

11 Air Nozzle

12 Air Nozzle Locking Ring

Product Familiarisation

EQ-4

Europe

EN-6

UK

580420_Z1MANPRO1.indd 6

02/07/2013 15:27