Installation, Caution – Comfort-Aire WDG Air Handler Series User Manual

Page 11

11

Installation, Operation & Maintenance

WDG AIR HANDLER SERIES

Heat Controller, LLC

CAUTION!

CAUTION! Installation of a factory supplied liquid line bi-

directional fi lter drier is required. Never install a suction line

fi lter in the liquid line.

CAUTION!

See compressor section IOM for refrigerant charge

information.

Line Set Installation

Figure 4 illustrates a typical installations of an air handler l matched

to an indoor compressor section. Table 1 shows typical line-set

diameters at various lengths. Lineset lengths should be kept to a

minimum and should always be installed with care to avoid kinking.

Line sets over 60 feet [18 meters] long are not recommended due to

potential oil transport problems and excessive pressure drop. If the

line set is kinked or distorted, and it cannot be formed back into its

original shape, the damaged portion of the line should be replaced.

A restricted line set will effect the performance of the system.

All brazing should be performed using nitrogen circulating at

2-3 psi [13.8-20.7 kPa] to prevent oxidation inside the tubing.

All linesets should be insulated with a minimum of 1/2” [13mm]

thick closed cell insulation. All insulation tubing should be

sealed using a UV resistant paint or covering to prevent

deterioration from sunlight.

When passing refrigerant lines through a wall, seal opening

with silicon-based caulk. Avoid direct contact with water

pipes, duct work, fl oor joists, wall studs, fl oors or other

structural components that could transmit compressor

vibration. Do not suspend refrigerant tubing from joists

with rigid straps. Do not attach line set to the wall. When

necessary, use hanger straps with isolation sleeves to

minimize transmission of line set vibration to the structure.

Installing the Indoor Coil and Lineset

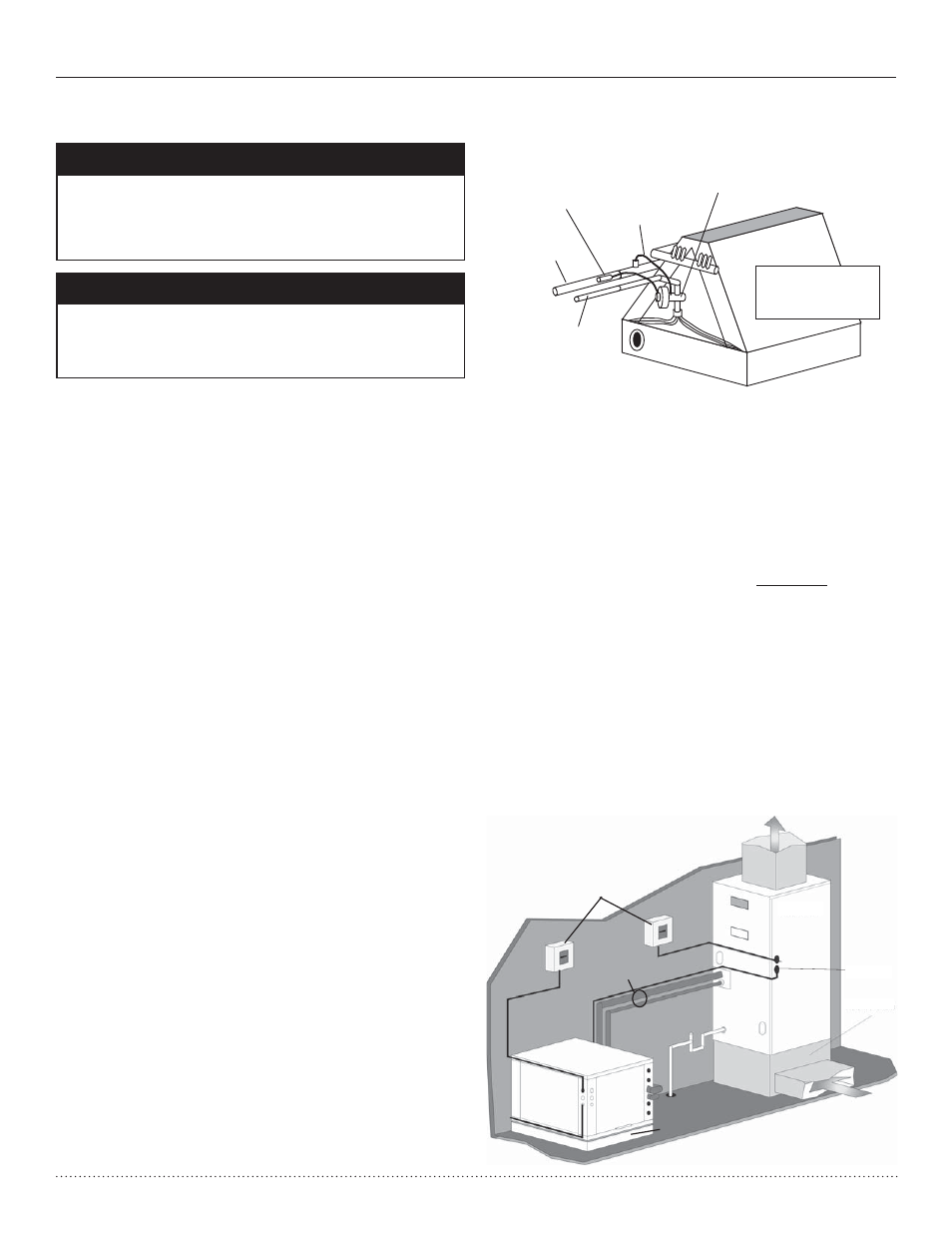

Figure 3 shows the installation of the lineset and TXV to a typical

indoor coil. Braze the copper line set to the coil. Nitrogen should be

circulated through the system at 2-3 psi

[13.8-20.7 kPa] to prevent

oxidation inside the refrigerant tubing. Use a low silver phos-copper

braze alloy on all brazed connections.

Installation

Figure 3: Air Coil Connection

TXV (‘IN’ toward

compressor section)

Suction Line

Liquid Line

Bulb

(Must be

Installed and

Insulated)

Equalizer

Line

TXV has internal

check valve

NOTICE! The air coil should be thoroughly washed with a fi lming

agent, (dishwasher detergent like Cascade) to help condensate

drainage. Apply a 20 to 1 solution of detergent and water. Spray

both sides of coil, repeat and rinse thoroughly with water. Care

should be taken not to overfl ow drain pan. Wash after connecting

condensate line.

Sensing Bulb

IMPORTANT: DO NOT perform any brazing with the TXV

bulb attached to any line. After brazing operations have been

completed, clamp the TXV bulb securely on the suction line at

the 10 or 2 o’clock position with the strap provided in the parts

bag. Insulate the TXV sensing bulb and suction line with the

provided pressure sensitive insulation (size 4” x 7”).

IMPORTANT: TXV sensing bulb should be located on a horizontal

section of suction line, just outside of coil box.

IMPORTANT: Always protect TXV from heat when brazing.

IMPORTANT: TXV sensing bulb is shipped unattached. Installer

must attach bulb to suction line after brazing and cooling line for

proper unit operation.

CAUTION! HFC-410A systems operate at higher pressures

than R-22 systems. Be certain that service equipment

(gauges, tools, etc.) is rated for HFC-410A. Some R-22 service

equipment may not be acceptable.

Figure 4: Typical Split/Air Handler Installation

Compressor Section

Low Voltage

Insulated

Linesets

Air pad or Extruded

polystryene

PVC Condensate

with vented trap

Power

Disconnects

Air

Handler

Low

Voltage

Return

Plenum