Barksdale Series 5620 User Manual

Page 12

____________________________________

____________________________________

Barksdale, Inc. 3211 Fruitland Avenue, Los Angeles CA 90058 (800)835-1060 www.barksdale.com Bulletin No. 272350-A, 07-05-13

12

8.0

TROUBLE SHOOTING

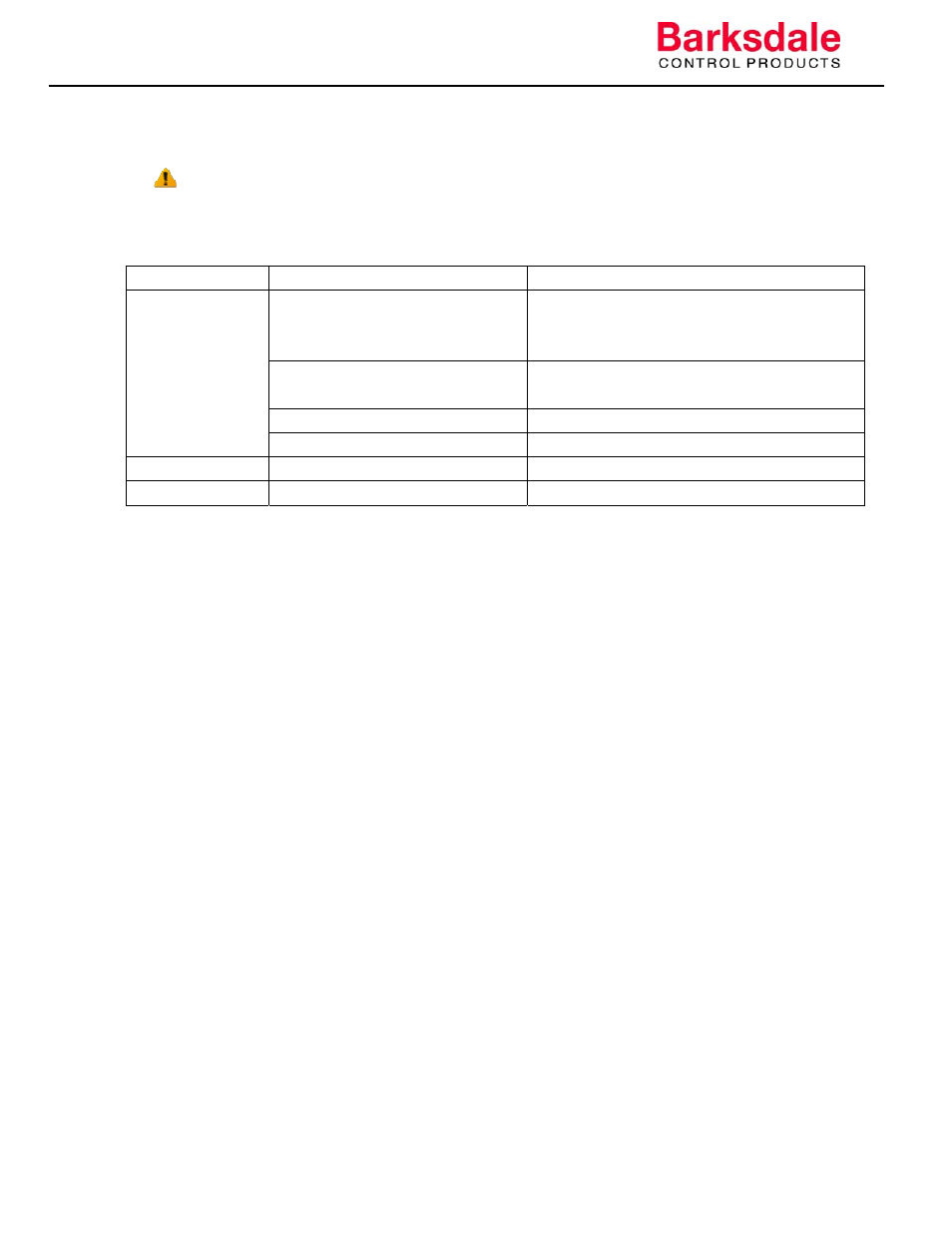

Caution: Chart is used as a quick trouble shooting tool and mainly for reference only. It does

not mean to list all possible causes and solutions to the problems as seen by the user on valve. Contact

factory or authorized dealers for technical support and issues.

PROBLEM

POSSIBLE CAUSE

SOLUTION / RECOMMENDATION

Handle does not

move

Incorrect valve plumbing

PRESS port for pressure source

RET return port is back to tank or atmosphere

‐ 250 psi back pressure max.

Return port is plugged

Return port cannot be plugged or line be

blocked.

Return port has restriction

Return port pressure is 250 psi or less.

Valve plumbed in series.

Return port pressure is 250 psi or less.

External Leakage

Loose connection

Tighten connections.

Internal Leakage

Valve handles not in detent.

Place handle in detent.

8.1 Maintenance

1. All Barksdale 4-Way Heavy Duty Control Valve are equipped with a grease

fitting in the housing. If media is oil-soluble greasing is not necessary, valve is

self-lubricated each time the valve is cycled. For non-oil based media valve can

be lubricated through this fitting. Frequency of lubrication depends entirely on

the duty cycle of the valve. An increase in handle load will indicate exactly what

lubrication schedule should be followed.

2. Disassemble and inspect valve, replace damaged/worn parts and O-rings every

two years or 2,000,000 cycles whichever occurs first.

3. At first sign of excessive internal leakage valve should be disassembled and

source of leakage repaired. Allowing the valve to continue in operation may

cause excessive wear or damage to other components. This is caused by the

escaping fluid which is generally in the form of a jet stream.