Series iii-l valve, Installation and operating instructions, For barksdale heavy duty integrated actuator valve – Barksdale Series III-L Valves User Manual

Page 10

Installation and Operating Instructions

Series III-L Valve

For Barksdale Heavy Duty Integrated Actuator Valve

____________________________________

____________________________________

Barksdale, Inc. 3211 Fruitland Avenue, Los Angeles CA 90058 (800) 835-1060 Bulletin No. 272346 Revision A

8.0

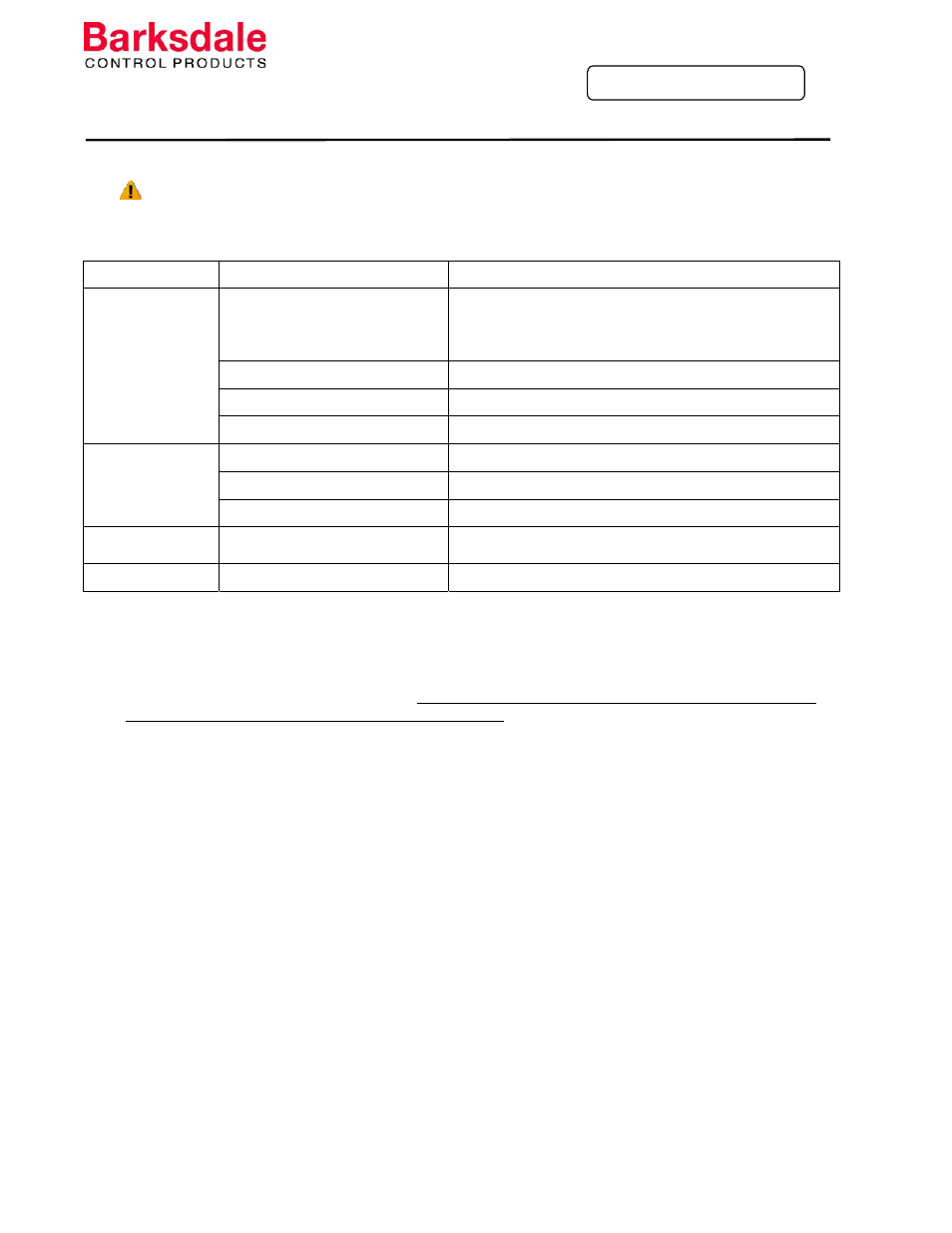

TROUBLE-SHOOTING

Caution Chart is used as a quick trouble shooting tool and mainly for reference only. It does not mean

to list all possible causes and solutions to the problems as seen by the user on the Series III-L. Contact

factory or authorized dealers for technical support and issues.

PROBLEM

POSSIBLE CAUSE

SOLUTION / RECOMMENDATION

Handle does not

move

Incorrect valve plumbing

PRESS port for pressure source;

CYL1 & CYL2 ports are for process

RET return port is back to tank or atmosphere - 250

PSI max back pressure

Return port is plugged

Return port cannot be plugged or line be blocked

Return line has restriction

Return port pressure is 250 PSI or less

Valve plumbed in series

Return port pressure is 250 PSI or less

No Actuation

No pilot pressure

Provide pressure to pilot line

Pilot line pressure blocked

Only one pilot port may be pressurized at a time.

Pilot line leaking

Tighten or replace pilot line

External

Leakage

Loose connections

Tighten connections

Internal leakage

Valve handle not in detent

Place handle in detent

9.0

TRANSPORT / STORAGE

Severe shock and vibration should be avoided during transport. Store it in a clean and dry environment.

Valves are ready for operation upon delivery. The protective port plugs should not be removed until

immediately before connecting the piping. To avoid damaging valve or/and position indicator, do

not lift or carry by the handle, or position indicator.

It is recommended to transport valve with the lifting equipment suitable for the weight to be moved. Do

not hook-up lifting equipment to accessory such as handle, or pressure bores. When using a

suspension belt it must be placed around the valve body, position indicator, providing edge protection

and ensuring weight distribution. Transport/storage temperature is recommended to be between

-40° C (-40° F) to +93°C (200°F). Protect existing sealing surface on the connections from damage. Do

not damage the corrosion protective layer.

10.0

DISPOSAL/RETURNS

Valves that have come in contact with health – threatening media must be decontaminated prior to

disposal or returned to Barksdale.

Follow proper Federal/ State and local regulations for appropriate disposal to protect the environment.